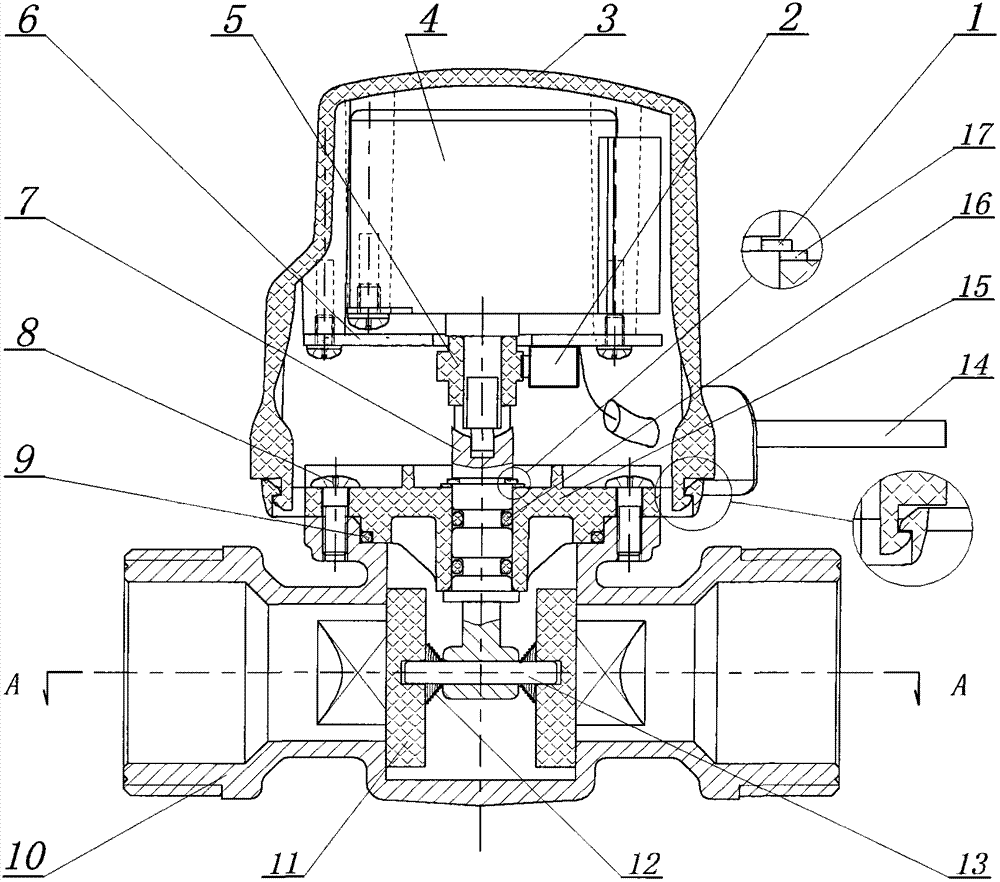

Electrically adjusted self-compensating plug valve

A technology of automatic compensation and electric adjustment, which is applied to the cocks, valve details, valve devices, etc. of the cutting device, which can solve the problems of manual adjustment and repair, affecting the normal operation of the supply system, etc., and achieves simplified structure, simplified structure, and production cost. falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

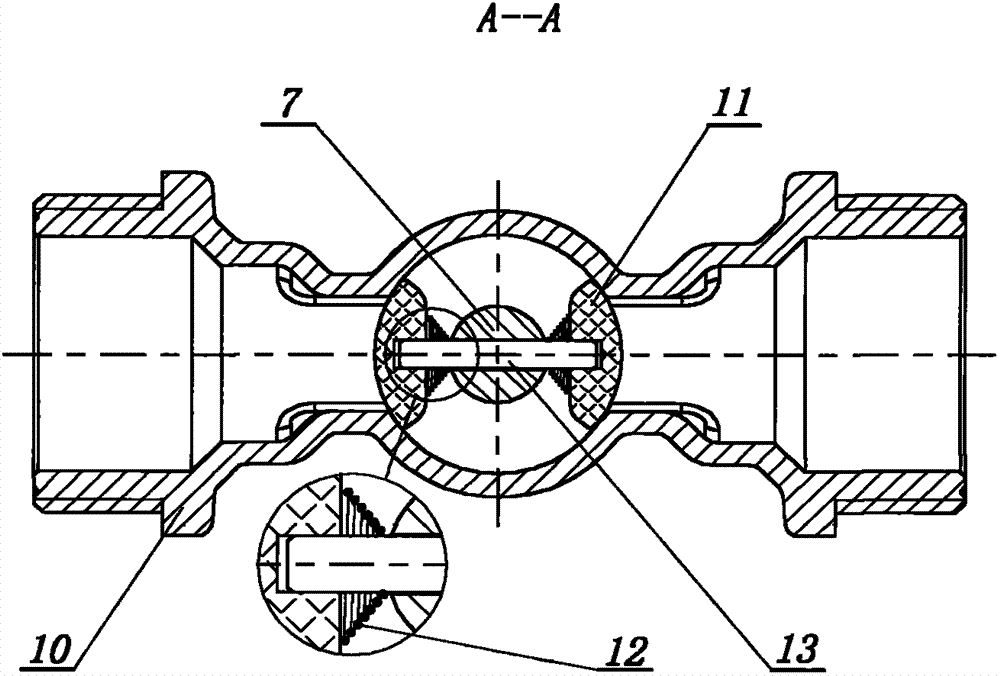

[0012] The valve body 10 is a three-way body, and the two ends of the straight-through are inlet and outlet, and are provided with external threads connecting the pipe; the center line of the bypass port is perpendicular to the center line of the straight-through pipe, and is arranged in the middle area of the straight-through pipe; the center of the bypass port extends to The intersection of straight pipes is a cylindrical hole, and the orifice is provided with a stepped flange connected to the lower casing 15 of the driver. A large sealing ring is arranged at the step, and threaded holes for mounting screws 8 are provided on the flange. The driver lower case 15 is made of nylon plastic, and is generally in the shape of a cylindrical step. The center is provided with a through hole for installing the valve stem 7 , and the plane is provided with a screw 8 mounting hole connected to the valve body 10 . The lower plane of the driver lower case 15 is provided with a cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com