Back plate component and liquid crystal display

A technology for a liquid crystal display and a backplane assembly, which is applied in the field of the backplane assembly and the liquid crystal display, can solve the problems that the thickness of the border of the liquid crystal display cannot be narrowed, and the maximum viewing area cannot be enlarged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Further details will be given below in conjunction with the embodiments shown in the accompanying drawings.

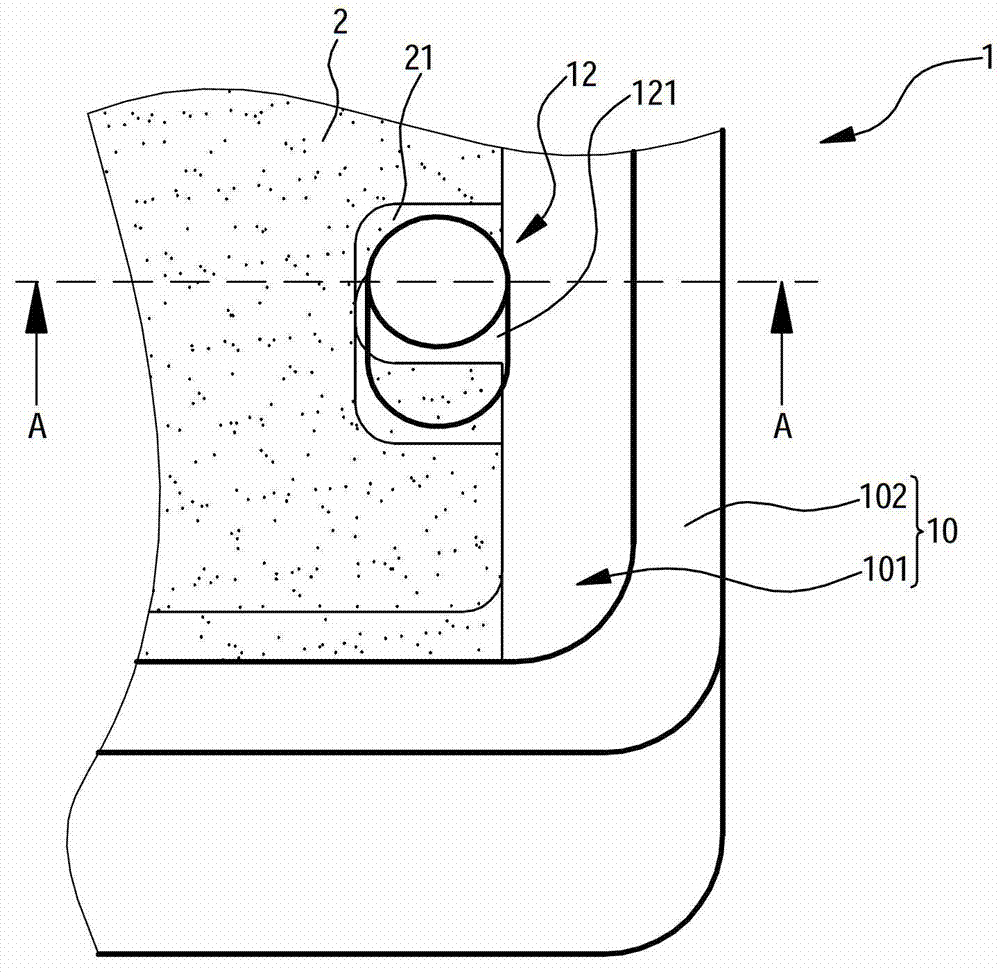

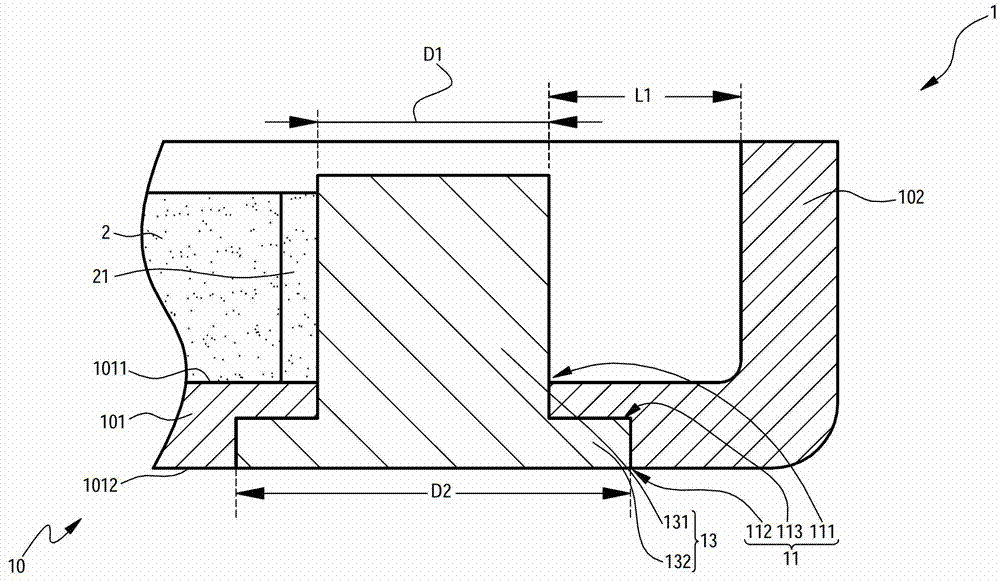

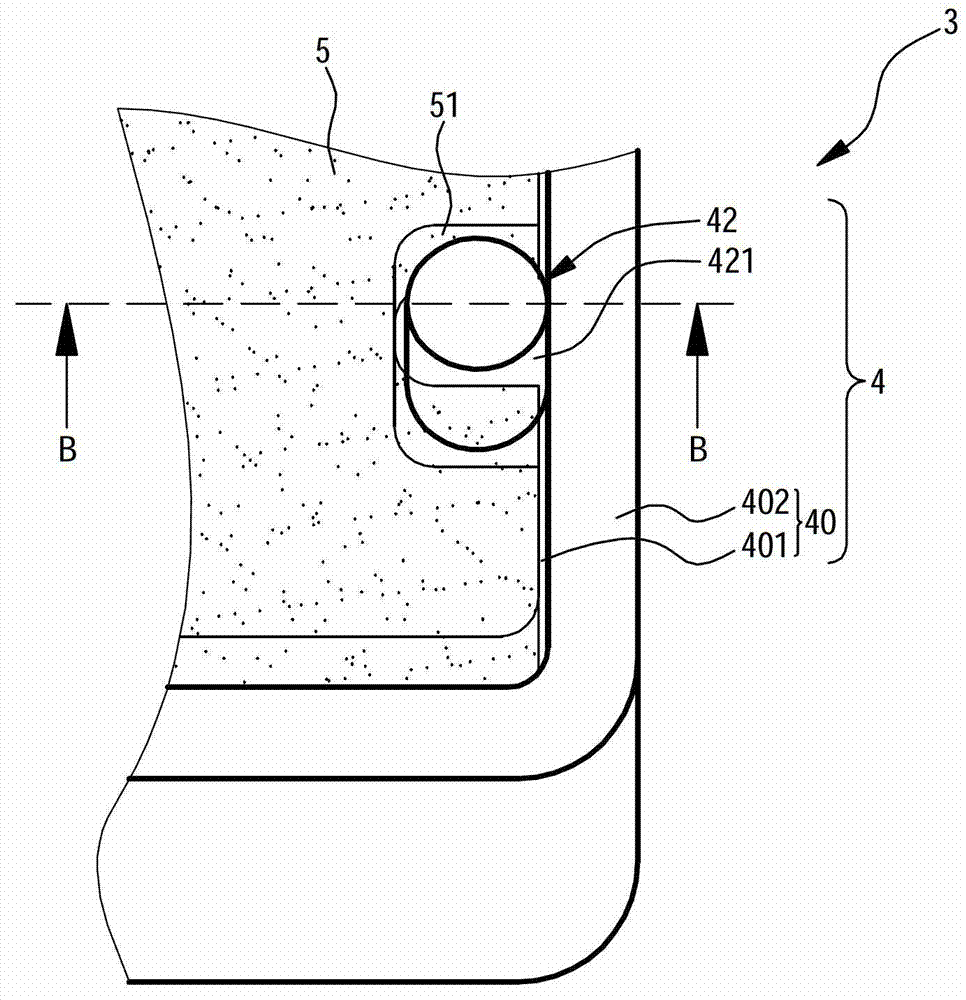

[0034] Please also refer to image 3 and Figure 4 , image 3 It is a structural diagram of a backplane assembly 4 of the present invention. Figure 4 It is an enlarged cross-sectional view of the backplane assembly 4 of the present invention along the section line BB.

[0035] The figure shows a partial structure of a backlight module 3 , the backlight module 3 includes: a backplane assembly 4 and an optical unit 5 . Firstly, the back plate assembly 4 is suitable for accommodating and positioning the optical unit 5 , and the back plate assembly 4 includes: a back plate 40 , a plurality of tapered holes 41 and a plurality of optical unit positioning posts 42 .

[0036] The backboard 40 includes: a plate 401 and an upright side 402 . The board 401 has a first surface 4011 and a second surface 4012 , and the second surface 4012 is opposite to the first surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com