Array substrate, display panel and display device

An array substrate and display area technology, which is applied to static indicators, semiconductor/solid-state device parts, instruments, etc., can solve problems such as unfavorable narrow borders and large width of the non-display area of the array substrate, so as to reduce the production yield, The effect of improving process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the array substrate, the display panel and the display device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0023] The shapes and sizes of the elements in the drawings do not reflect the real proportion of the array substrate, but are only intended to schematically illustrate the content of the present invention.

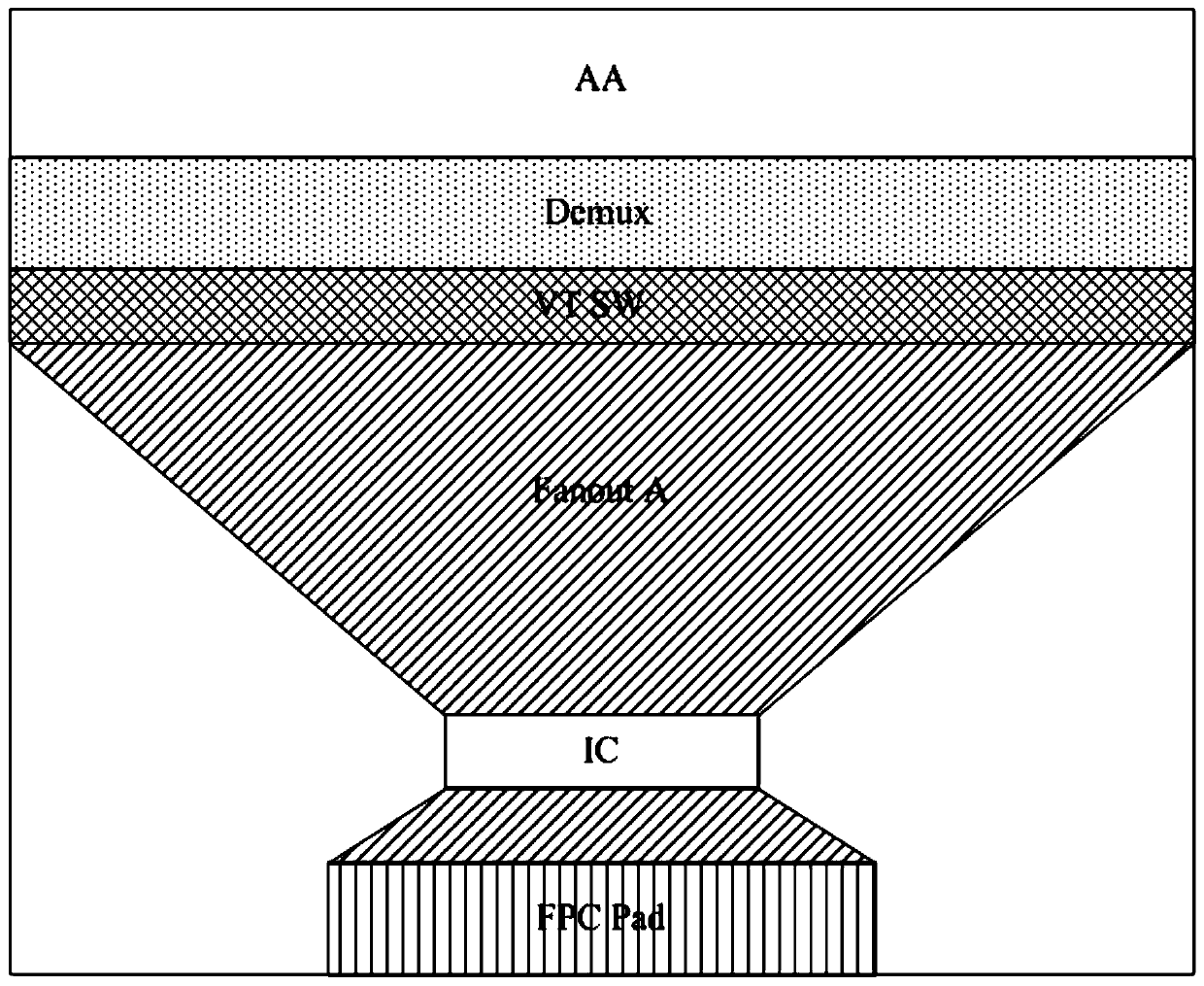

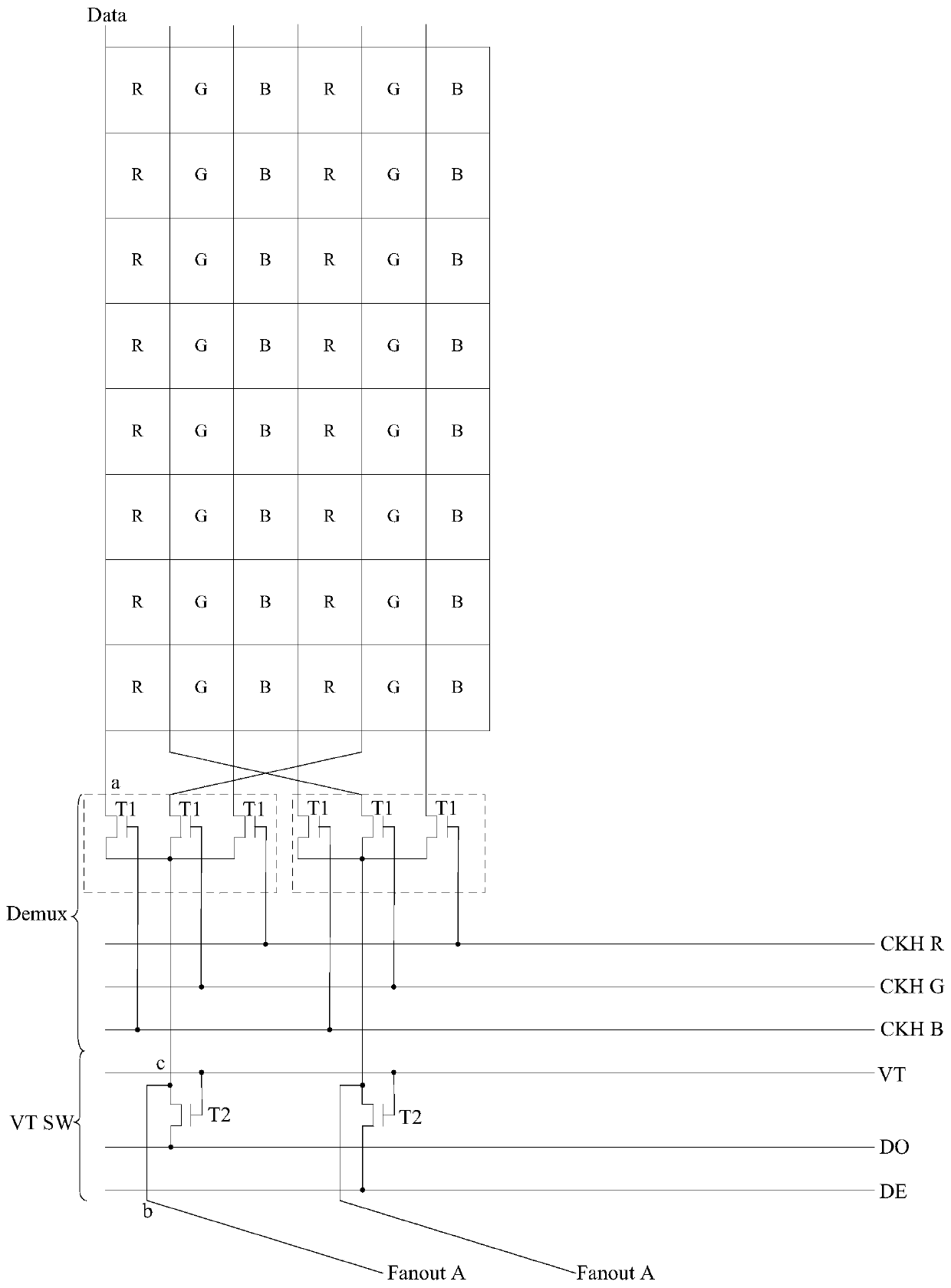

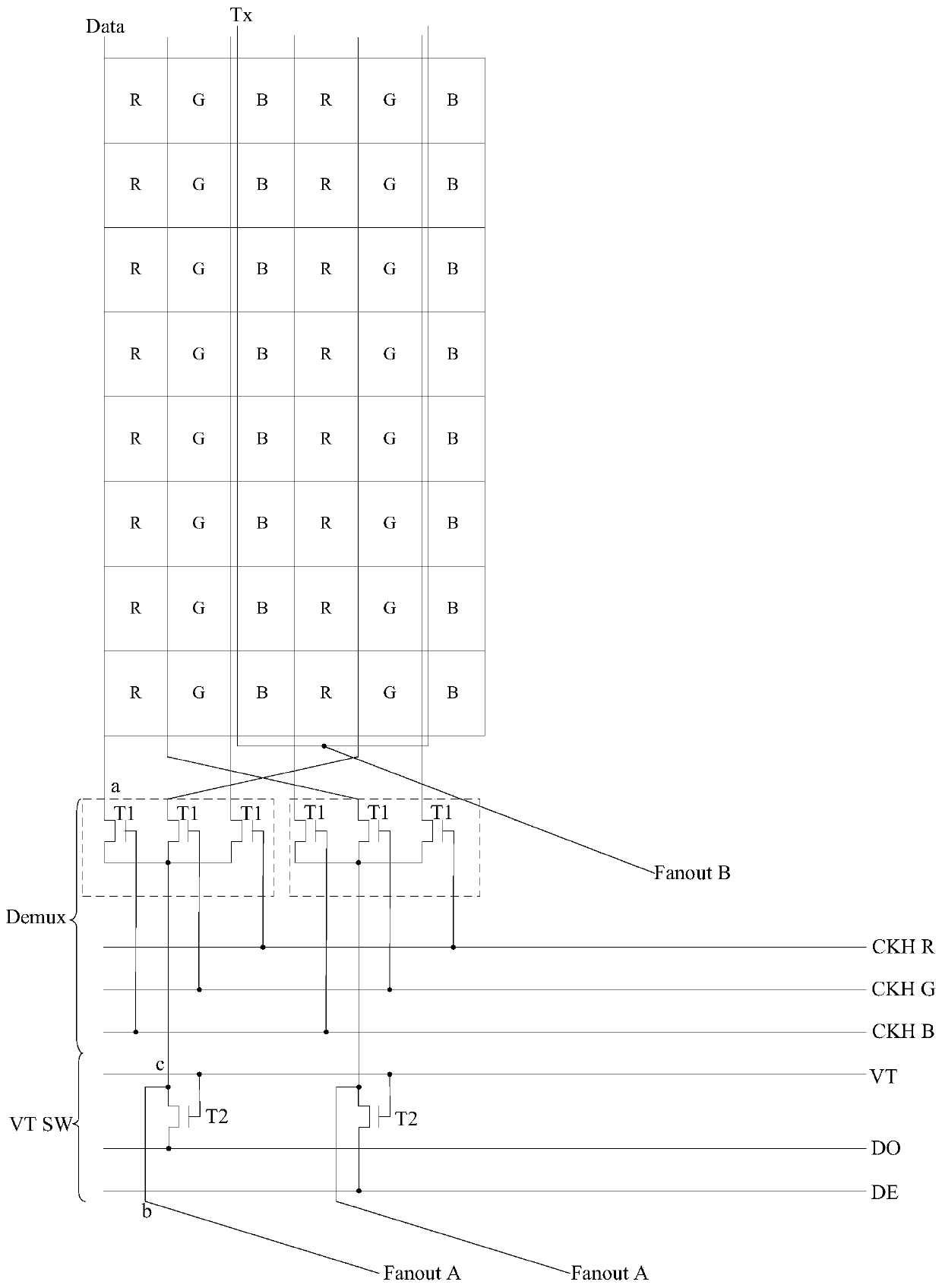

[0024] Currently, in some display array substrates, at one side of the non-display area such as the lower frame (border), such as Figure 1a As shown, it generally includes: demultiplexer component Demux, test switch component VT SW, data signal sector trace Fanout A, driver chip IC and flexible circuit board pad FPC Pad and other components.

[0025] At the lower frame, from the display area to the outer edge, the demux component Demux, the test switch component VT SW, the data signal sector trace Fanout A, the driver chip IC and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com