Backlight module, display panel and preparation method of backlight module

A backlight module, one-sided technology, applied in optics, nonlinear optics, identification devices, etc., can solve problems such as unstable quality of backlight modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

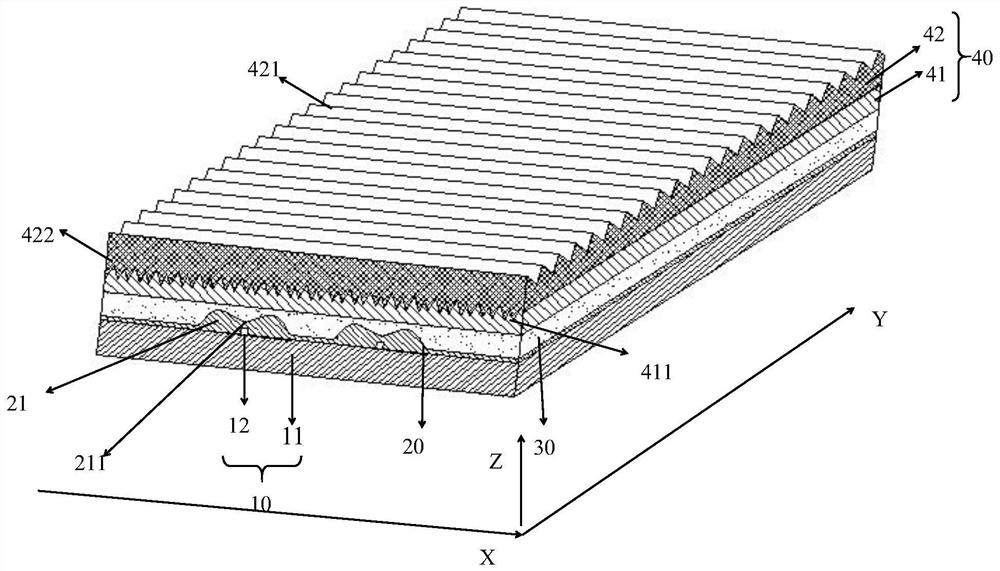

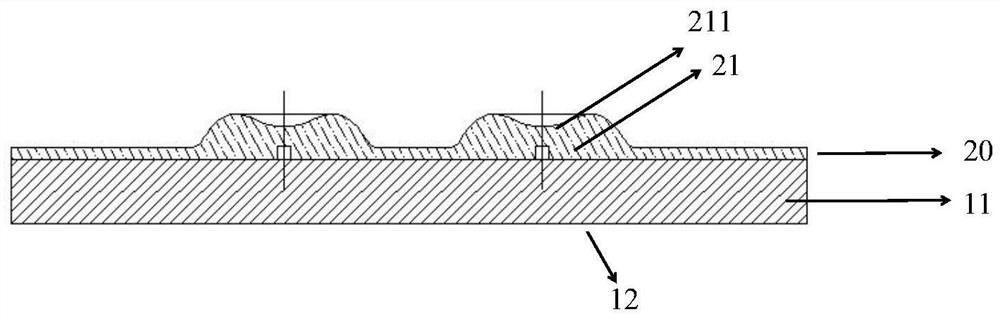

[0051] refer to figure 2 , shows a backlight module, the present invention provides a backlight module in one aspect, the backlight module includes: a lamp board 10 and a plurality of adhesive layers stacked on the lamp board 10, the lamp The board includes a substrate 11 and a plurality of point light sources 12 distributed on the substrate 11, and the plurality of adhesive layers include:

[0052] a light-scattering layer 20 covering the plurality of point light sources 12;

[0053] a diffusion layer 30 coated on the side of the light scattering layer 20 facing away from the lamp panel 10;

[0054]The correction layer 40 coated on the side of the diffusion layer 30 away from the light-scattering layer 20, the correction layer 40 is used to correct the light output by the diffusion layer 30 toward the normal direction of the light exit surface of the correction layer 40.

[0055] In the embodiment of the present invention, the function of the lamp board is mainly to arrang...

Embodiment 2

[0084] refer to Figure 12 , showing a flow chart of the steps of a method for preparing a backlight module provided by an embodiment of the present invention; the method specifically includes the following steps:

[0085] Another aspect of the present invention is to provide a method for preparing a backlight module, including:

[0086] Step 201, provide a lamp board, the lamp board includes: a substrate and a plurality of point light sources distributed on the substrate.

[0087] Among them, the function of the lamp board is mainly to arrange lamps, and the substrate serves as the carrier of the entire point light source.

[0088] Wherein, preparing a plurality of adhesive layers on the lamp panel specifically includes the following steps:

[0089] Step 202, coating a light-scattering layer on the lamp panel so that the light-scattering layer covers the multiple point light sources.

[0090] In the embodiment of the present invention, the light-scattering layer mainly exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com