Novel boiler igniting mechanism

A boiler ignition, a new type of technology, applied in the direction of combustion type, use of multiple fuels, combustion methods, etc., can solve the problems of insufficient combustion of heavy oil, large amount of heavy oil, waste, etc., to achieve fast operation response speed and extremely high oil consumption , The effect of saving fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

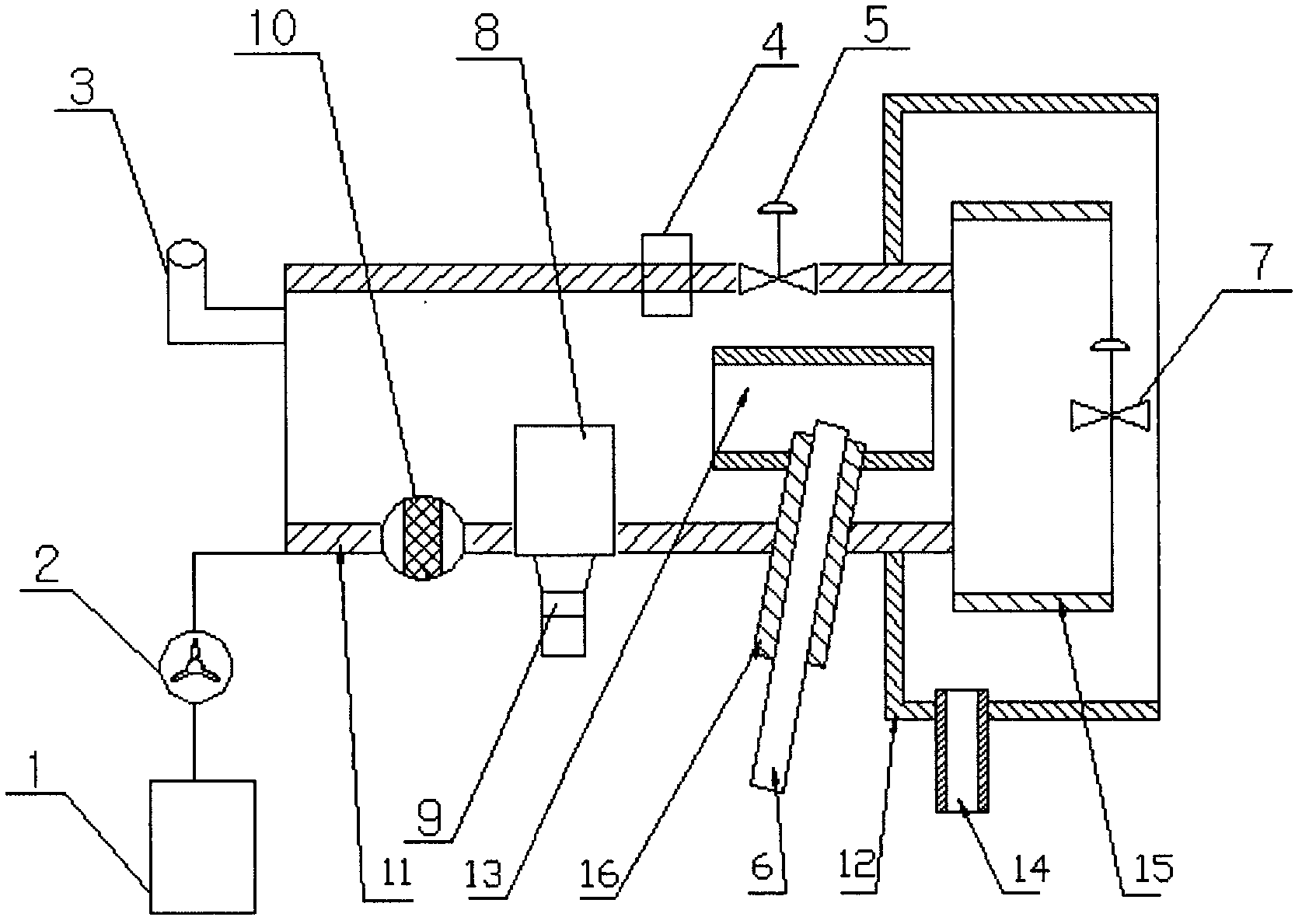

[0008] The ignition mechanism has a compressor 3, which is connected to the fuel gun 6 after connecting the compressor 3, the gas storage tank 4, and the shut-off valve 5; Connect with the fuel gun 6; connect the launch end of the transducer 9 with the atomization chamber 8; install the primary combustion chamber 13 on the pipeline 11, and the protective tube 16 communicates with the primary combustion chamber 13 from the outside of the pipeline 11, and the fuel oil The gun 6 is inserted into the primary combustion chamber 13 from the protective pipe 16, and the secondary combustion chamber 15 is installed at the pipeline 11 position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com