Light kiln vehicle

A kind of kiln car and light technology, which is applied in the direction of furnace type, furnace, lighting and heating equipment, etc. It can solve the problems of poor sealing, heavy vehicle weight, corrosion, etc., and achieve strong practical value, low cost and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

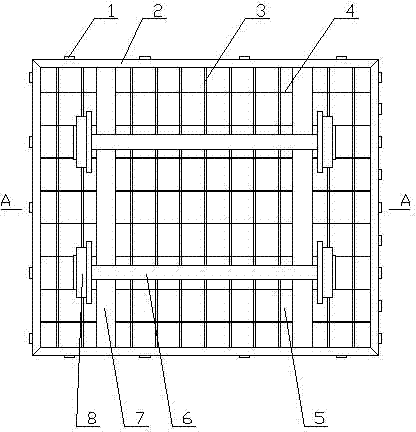

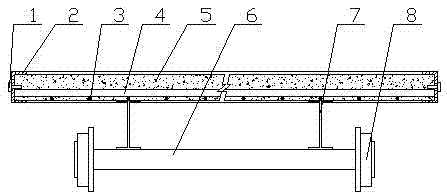

[0015] In the accompanying drawings, this light-duty kiln car includes a rectangular car body frame welded by channel steel 2, threaded steel 3, strip steel 4 and I-beam 7; the bottom of I-beam 7 is fixedly connected with kiln car Axle 6 and kiln wheel 8; the car body frame is poured with a 10 cm thick fireproof and heat-resistant concrete car surface 5, which increases the stability and sealing of the kiln car.

[0016] The car body frame is made of two equal-length and parallel I-beams 7 as the main support frame; the top of the I-beams 7 is equidistantly provided with threaded steel 3 in the same direction; The strip 4.

[0017] The distance between the I-beams 7 is not greater than 2 / 4 of the width of the kiln car.

[0018] The intersection angle between the rebar 3 and the strip 4 is 90 degrees.

[0019] The steel strips 4 are erected, and the distance between them is 17-23 centimeters, preferably 20 centimeters; the distance between the rebars 3 is 12-18 centimeters, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com