Water medium explosion technology

A water medium and technical technology, applied in the field of blasting technology, can solve the problems of harsh operation, high cost, strict requirements on blasting direction, etc., and achieve the effects of low blasting cost, light damage and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

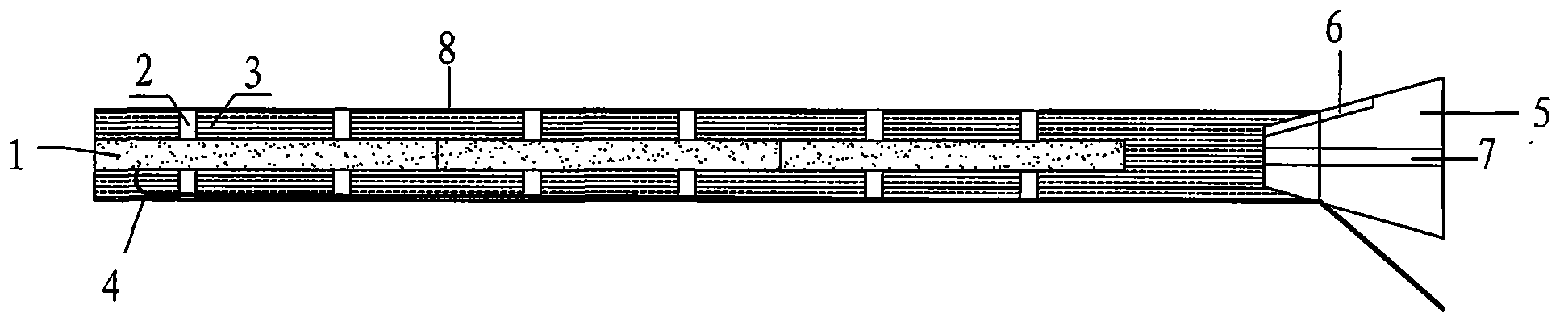

[0015] Such as figure 1 Shown, a kind of water medium blasting technology of the present invention: (1) select detonation point, drill hole, adopt common 2# rock emulsion explosives, calculate the charge of every hole; Frame 2 adopts the continuous charging method of fine powder coils, connects the powder coil 1 and the nonel tube 4, and loads them into the blast hole 8 in sequence; (3) put the blast hole plug 5 with the air guide groove 6 and the water injection hole 7 At the blasthole orifice, start injecting water 3 from the water injection hole 7 of the blasthole plug 5, and the air in the hole is discharged from the air guide groove 6; (4) When the water 3 is filled, quickly insert a small piece of foam into the water injection hole 7 Simultaneously, the blast hole plug 5 is pushed into the blast hole, the blast hole 8 is closed, and then the blast hole 8 is blocked with blasting mud; (5) detonating, the water 3 is equivalent to one deck film at the moment of blasting, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com