Novel sliding table saw

A sliding table saw, a new type of technology, applied in the direction of sawing components, sawing equipment, auxiliary sawing devices, etc., can solve the problems of affecting the service life and processing accuracy, affecting the mechanical accuracy, and wood chips flying to the machine, etc., to achieve simple structure, Improve sanitation and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

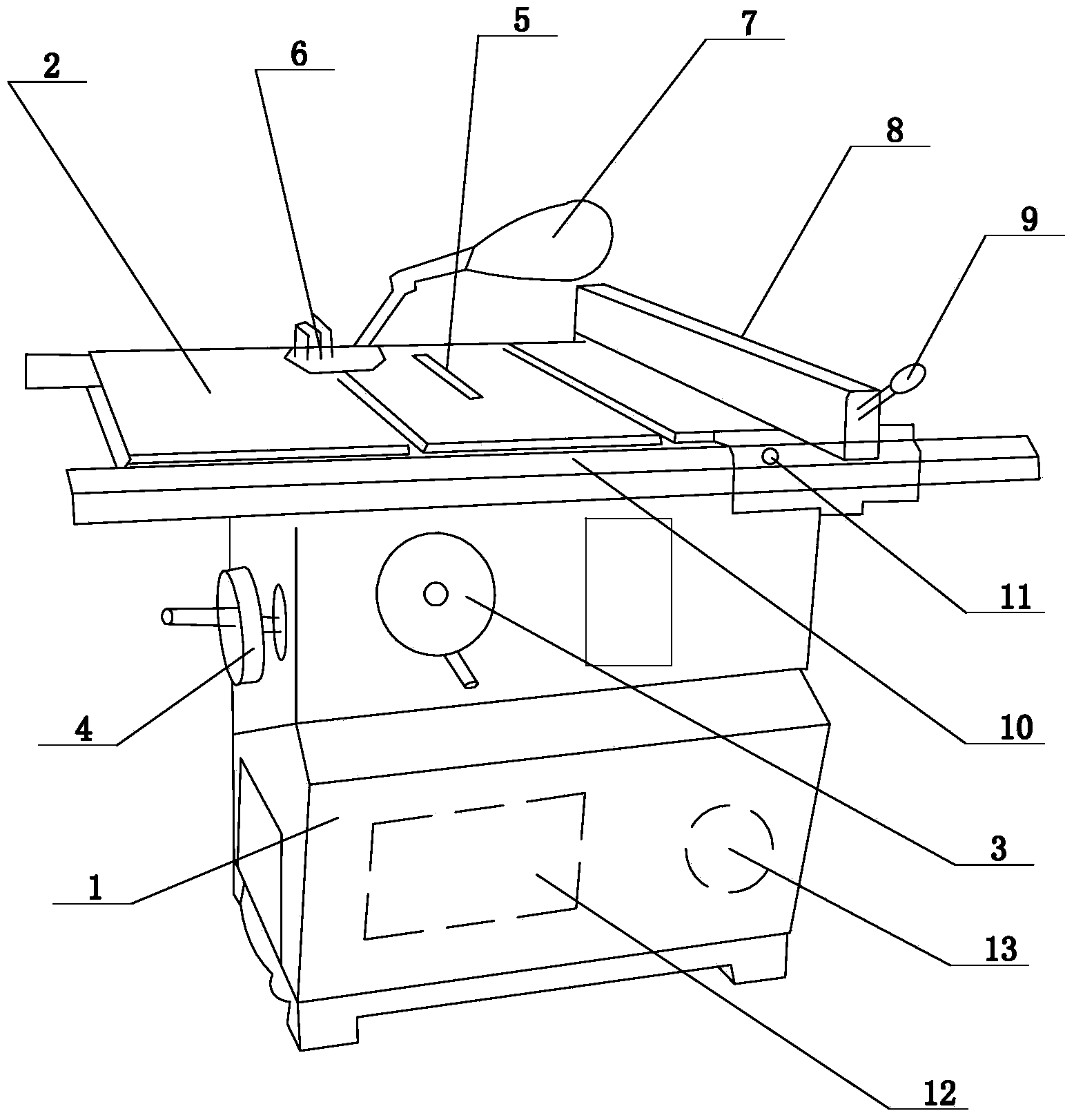

[0011] see figure 1 , the specific embodiment adopts the following technical solutions: it includes a base 1, a fixed table top 2, a saw blade lifting hand wheel 3, a saw blade inclination adjustment hand wheel 4, a saw blade groove 5, a mobile baffle plate 6, a safety shield 7, Move the stopper 8, the stopper adjustment rod 9, the scale 10, the transparent pointer 11, the dust suction device 12, the motor 13; the fixed table top 2 is arranged on the base 1, and the front side of the fixed table top 2 is provided with a saw blade lifting hand wheel 3, The side wall of the base 1 is provided with a saw blade inclination adjustment handwheel 4, and the middle of the fixed table 2 is provided with a saw blade groove 5, and a safety protection cover 7 is provided above the saw blade groove 5, and the safety protection cover 7 is a hollow safety protection. cover, the tail of the safety shield 7 is connected with the dust suction device 12, the dust suction device 12 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com