Multi-circle code converter based on mechanical gear set circle count

An encoder converter and gear set technology, which is applied in the direction of using optical devices to transmit sensing components, etc., can solve the problems of inaccurate memory number of turns, inability to remember the number of turns, limiting the application range of multi-turn absolute rotary encoders, etc., to achieve accurate The effect of memory laps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

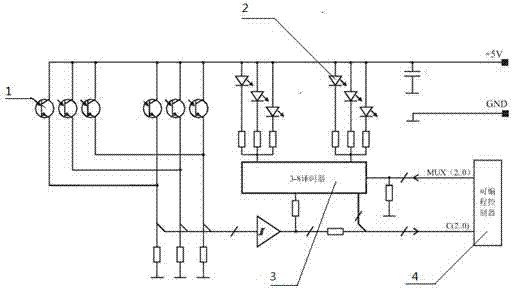

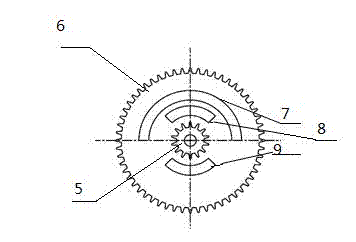

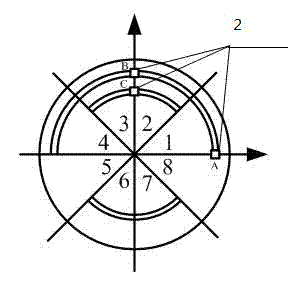

[0021] A multi-turn code converter based on the number of turns of a mechanical gear set, including a programmable controller 4 and 1 to 8 groups of photoelectric conversion mechanisms, each group of photoelectric conversion mechanisms includes an intermediate transmission gear, three light-emitting diodes 2 and light-emitting diodes The three phototransistors 1 corresponding to the diodes one by one, the light emitting diode 2 and the phototransistor 1 are respectively arranged on both sides of the intermediate transmission gear, and there is a light-transmitting groove on the intermediate transmission gear. The light-transmitting groove includes an inner ring groove and an outer ring arranged concentrically. The inner ring groove is a 90° fan-shaped groove 8,9 arranged symmetrically in two sections, the outer ring groove is a 180° semicircular groove 7, the center of the inner ring groove on the same side of the outer ring groove and the center of the outer ring groove and Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com