Ultrasonic wave heat testing device

A test device, ultrasonic technology, applied in the direction of measuring device, heat measurement, calorimeter, etc., can solve the problems of flow measurement stability and measurement accuracy, and achieve the effect of simple structure, accurate calculation accuracy and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

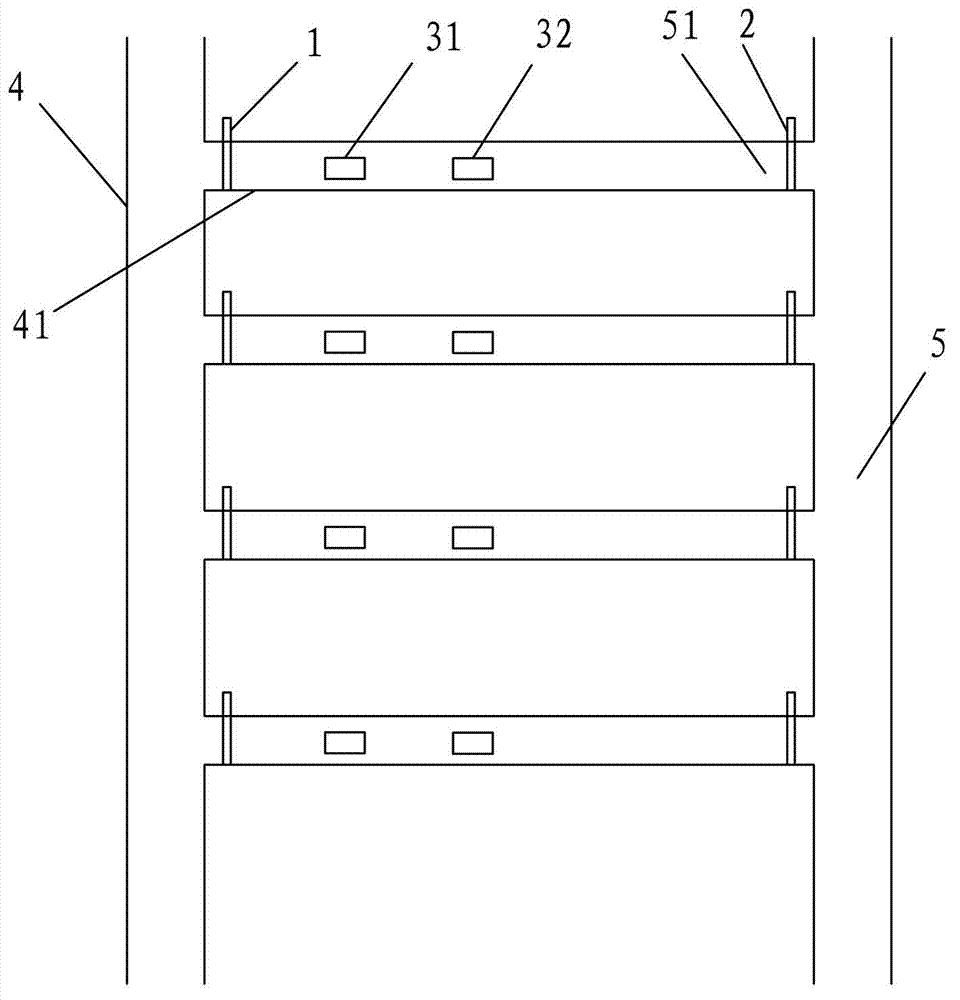

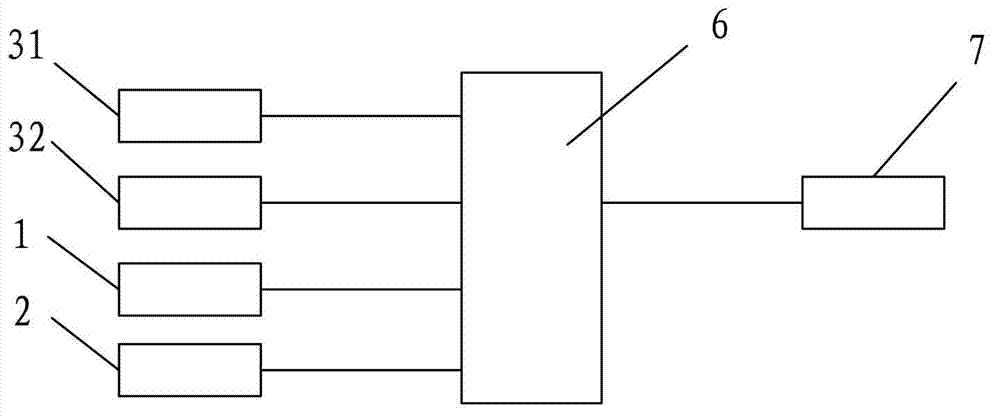

[0013] An ultrasonic heat testing device mainly includes a temperature sensor 1 and a temperature sensor 2 2, a pair of ultrasonic transceivers 31, 32, a controller unit 6, and a display instrument 7.

[0014] The temperature sensor one 1 and the temperature sensor two 2 have the same structure, but the installation positions are different, the temperature sensor one 1 is located at the outlet of the water supply, and the temperature sensor two 2 is located at the return water of the water supply. For a community or a user group composed of multiple users, a plurality of unit water supply pipes 41 are set up from the water supply main pipe 4, and then the return water of each user is recovered from the unit return water pipe 51 and enters the return water main pipe 5 for recovery. When measuring the heat usage state of a single user, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com