A Bearing Fault Prediction Method Based on Gaussian Process Regression

A Gaussian process regression and fault prediction technology, applied in special data processing applications, instruments, electrical and digital data processing, etc. issues of sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

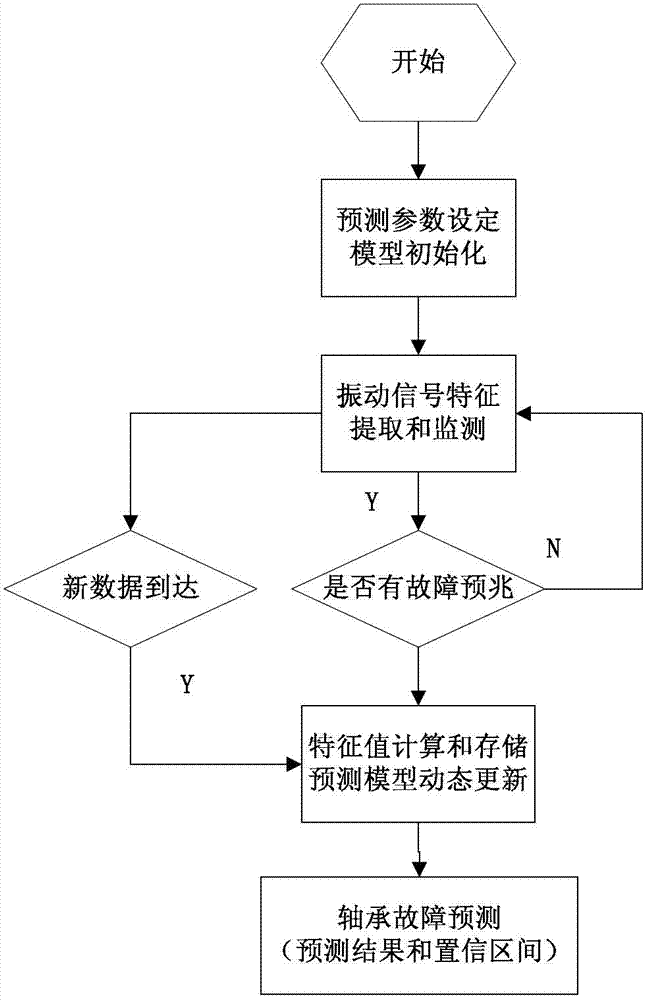

[0039] See figure 1 , the present invention, a bearing fault prediction method based on Gaussian process regression, the specific steps of the method are as follows:

[0040] Step 1: Set the parameters of the forecasting system and initialize the Gaussian process regression model.

[0041] Set the prediction system Judgment Threshold 1 and Judgment Threshold 2. When the characteristic parameters are higher than the judgment threshold 1, it is judged that the bearing is in a sub-healthy state, and the fault prediction model is used for fault prediction; when the predicted characteristic parameters reach the judgment threshold 2, it is judged that the bearing is about to fail and should be repaired and replaced.

[0042] The determination threshold should be set through self-study combined with previous experience. For dimensioned indicators ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com