Single FPC board for connecting multiple modules and touch sensitive display module using same

A flexible circuit board and touch display technology, which is applied in printed circuit parts, structural connection of printed circuits, printed circuit assembly of electrical components, etc., can solve problems such as increasing cost and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

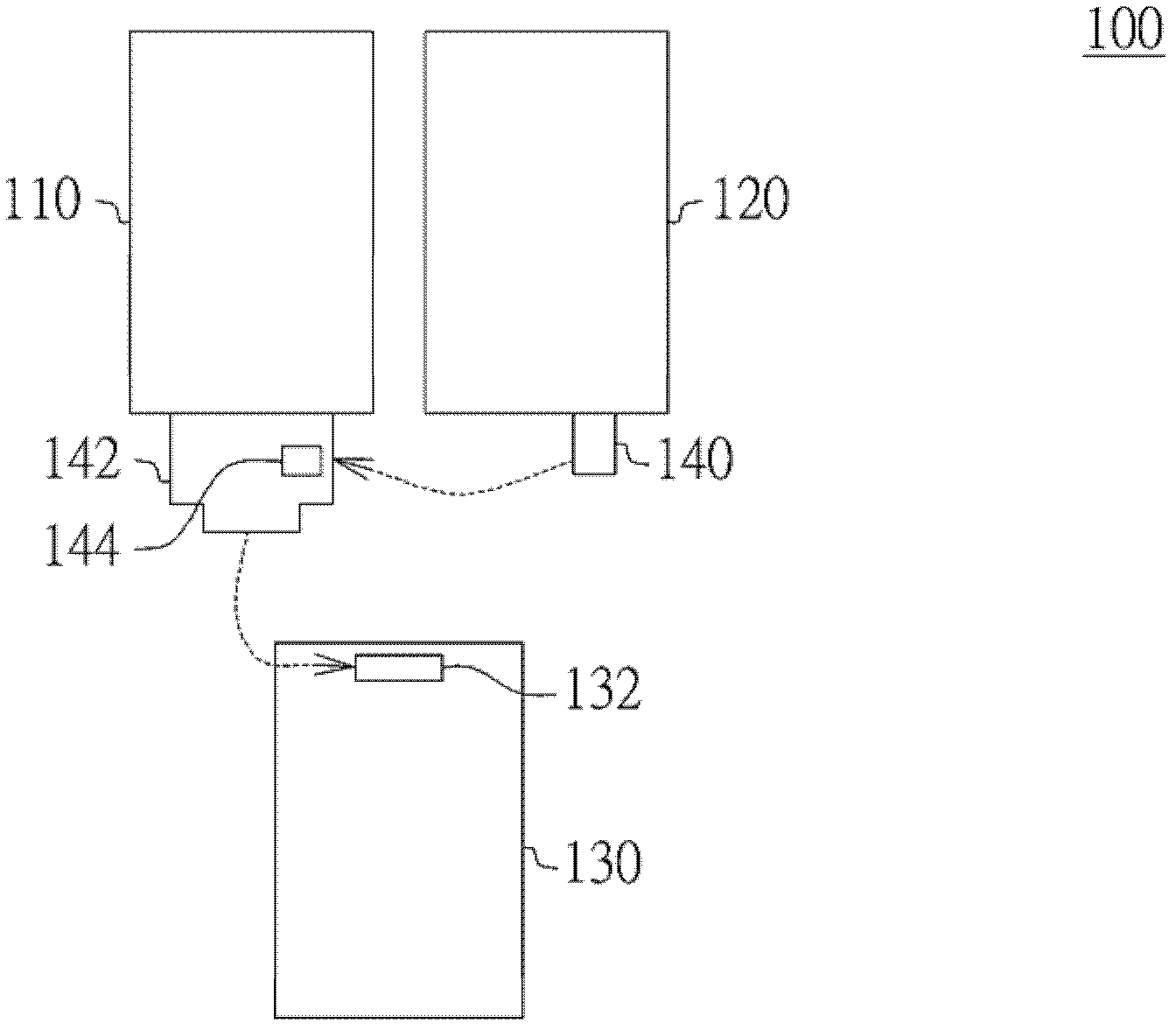

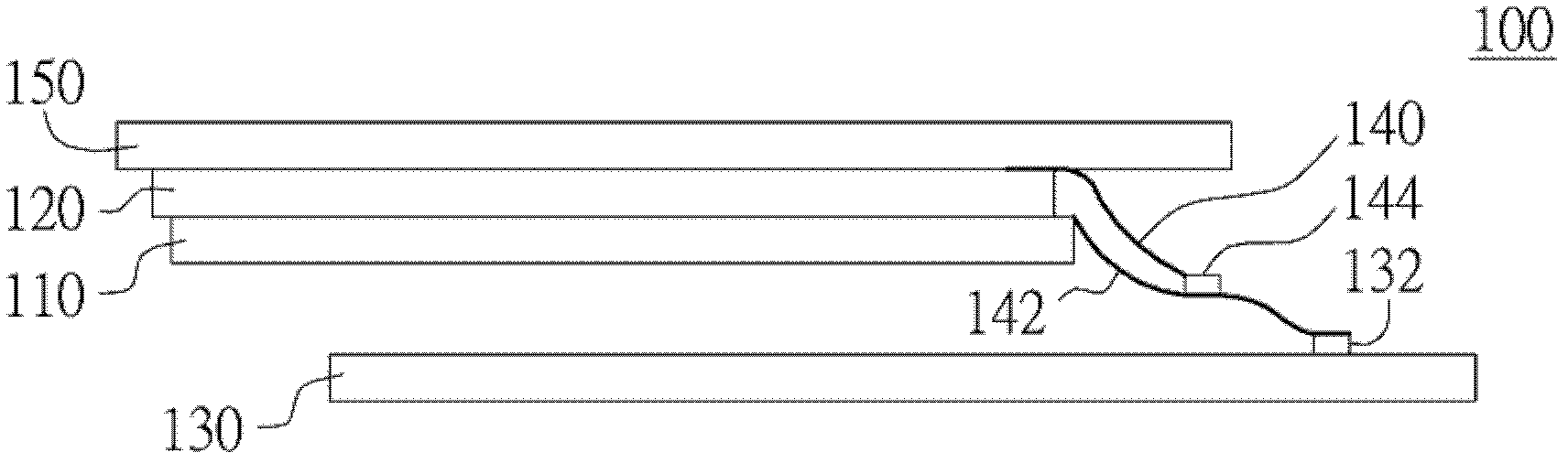

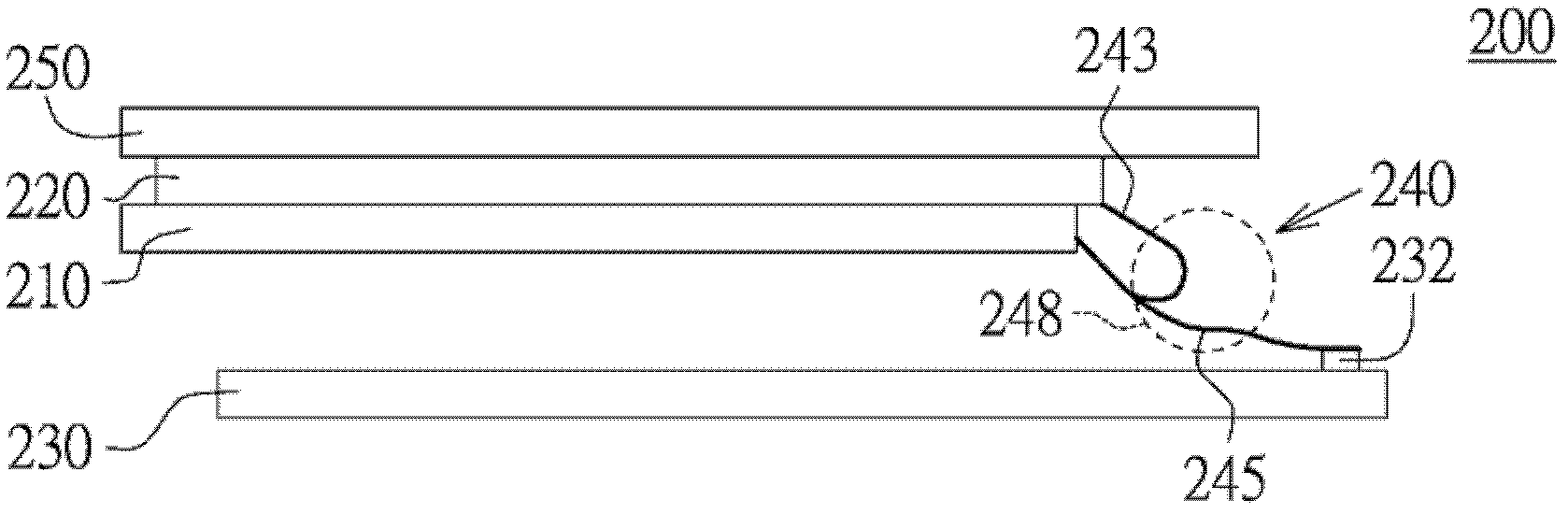

[0052] Please refer to Figure 3A ~ Figure 3C and Figure 4 ,in Figure 3A ~ Figure 3C The assembly structure diagrams of the touch display module according to an embodiment of the present invention are shown respectively. Figure 4 A schematic diagram of a single-chip flexible circuit board connecting multiple modules according to an embodiment of the present invention is shown. The touch display module 200 includes a first module 210 , a second module 220 , a third module 230 and a single-chip flexible circuit board 240 . The one-piece flexible circuit board 240 is connected to the first module 210 , the second module 220 and the third module 230 . The first module 210 is, for example, a display panel. The second module 220 is, for example, a touch panel, and is disposed on the first module 210 . The third module 230 is, for example, a motherboard, and may be adjacent to the first module 210 . Preferably, the first module 210 is disposed between the second module 220 a...

no. 2 example

[0058] Please refer to Figure 6A ~ Figure 6C and Figure 7A ~ Figure 7B ,in Figure 6A ~ Figure 6C The assembly structure diagrams of the touch display module according to an embodiment of the present invention are shown respectively. Figure 7A and Figure 7B Schematic diagrams showing a single-chip flexible circuit board connecting multiple modules according to two embodiments of the present invention, both of which can be applied to Figure 6A ~ Figure 6C assembly structure. The touch display module 300 includes a first module 310 , a second module 320 , a third module 330 and a single-chip flexible circuit board 340 . The first module 310 is, for example, a display panel. The second module 320 is, for example, a touch panel. The third module 330 is, for example, a motherboard. In one embodiment, the touch panel can be attached to the lower surface of the cover plate 350 (such as Figure 6A As shown), it is a touch panel of an out cell solution, or a transparent co...

no. 3 example

[0065] Figure 9A ~ Figure 9B Schematic diagrams of single-chip flexible circuit boards connected to multiple modules according to two embodiments of the present invention are respectively shown. The one-piece flexible circuit board 440 has a single film 441 . The film 441 has a first module connecting portion 442 , a second module connecting portion 444 , a third module connecting portion 446 , a first slot S1 and a second slot S2 . These two embodiments are similar to the second embodiment, the main difference is that the first slot S1 and the second slot S2 are located on the same side of the film 441, and the second module connecting portion 444 is located between the first slot S1 and the second slot. between slots S2.

[0066] In these two embodiments, the first module connection part 442 is divided into a first signal connection part 442 a and a second signal connection part 442 b according to different signal sources. Wherein, the first slot S1 is separated between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com