Filter element with guide shaft

A filter element and guide channel technology, which is applied in the direction of dispersed particle filtration, vehicle parts, household appliances, etc., and can solve the problem of damage to corrugated boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

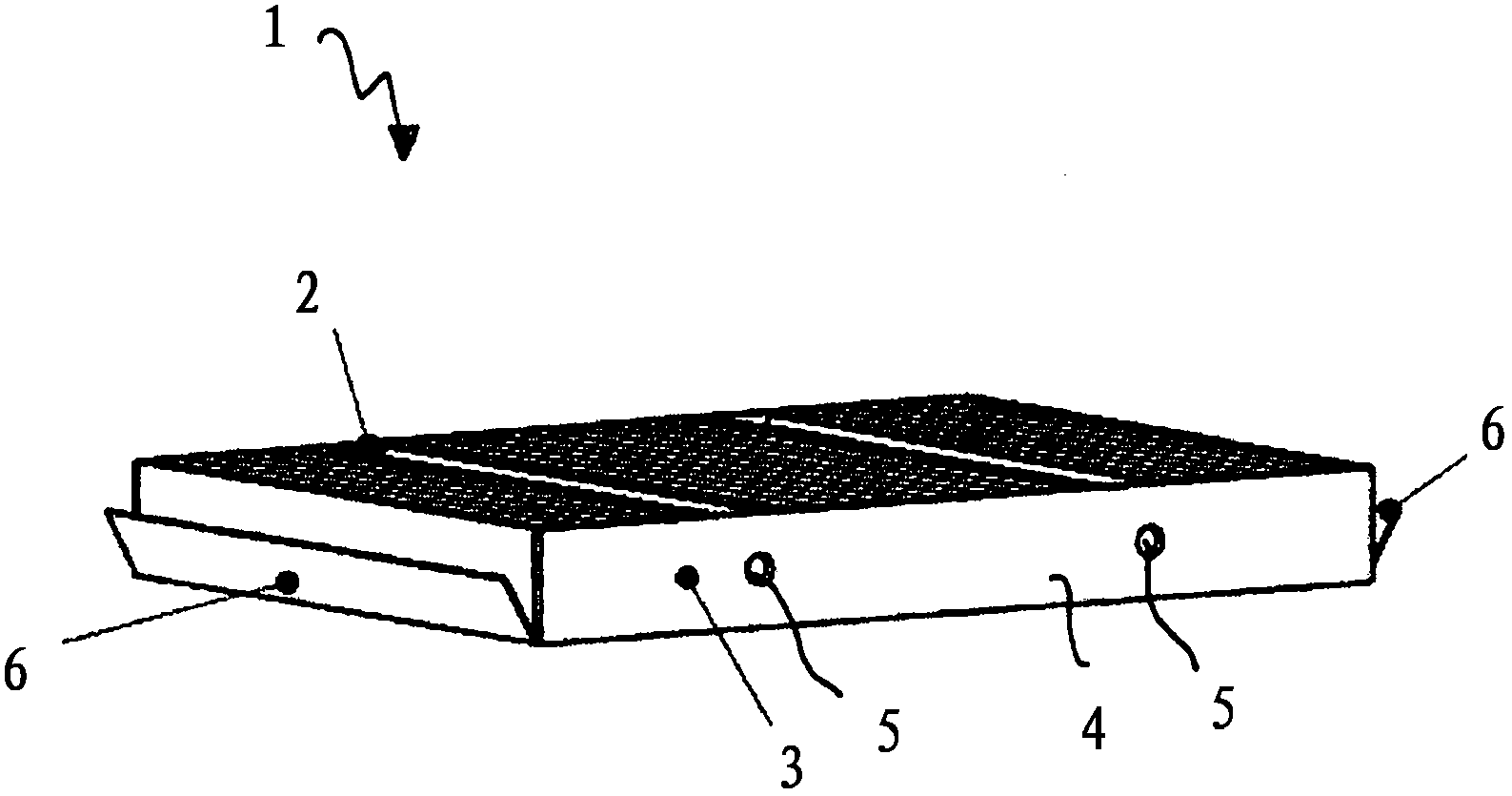

[0040] figure 1 A cuboid filter element 1 is shown in perspective for installation in a housing of a ventilation or air conditioning system. The filter element 1 comprises a bellows box 2 which has bellows and an end face which can face the wall of the housing. The end side 3 is surrounded by an edge strip 4 into which a through-hole 5 for a guide pin is introduced.

[0041] Furthermore, the filter element 1 has side strips 6 from which V-shaped sealing webs protrude. The corrugated box 2 is made of non-woven fabric. The edge strip 5 is likewise made of non-woven fabric. The side strips 6 are also made of non-woven fabric, apart from the V-shaped protruding sealing flaps.

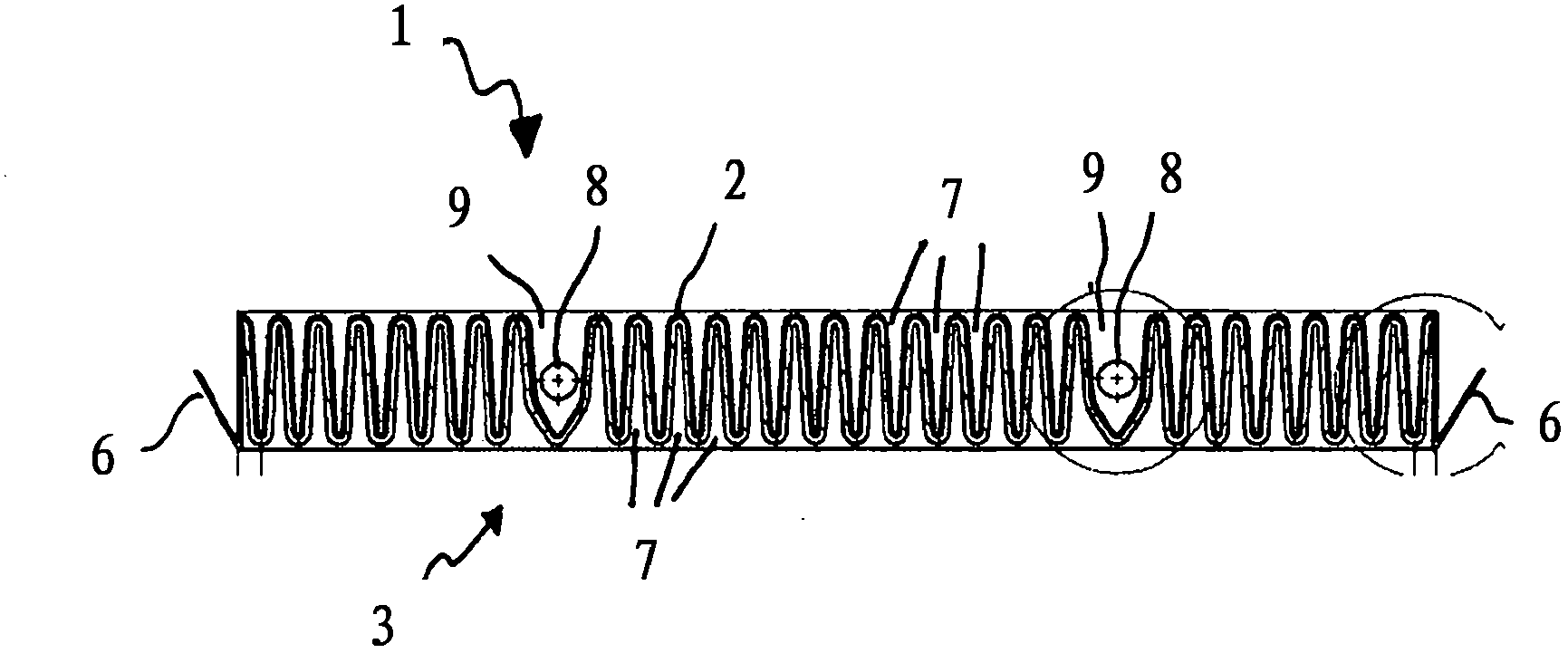

[0042] figure 2 Shows figure 1 A cross-sectional view of a cube-shaped filter element 1 .

[0043] figure 2 Shown is a filter element 1 for installation in a housing of a ventilation or air-conditioning system, which comprises a bellows box 2 with corrugations and an end side 3 which can face the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com