Patents

Literature

31results about How to "Wrinkled evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

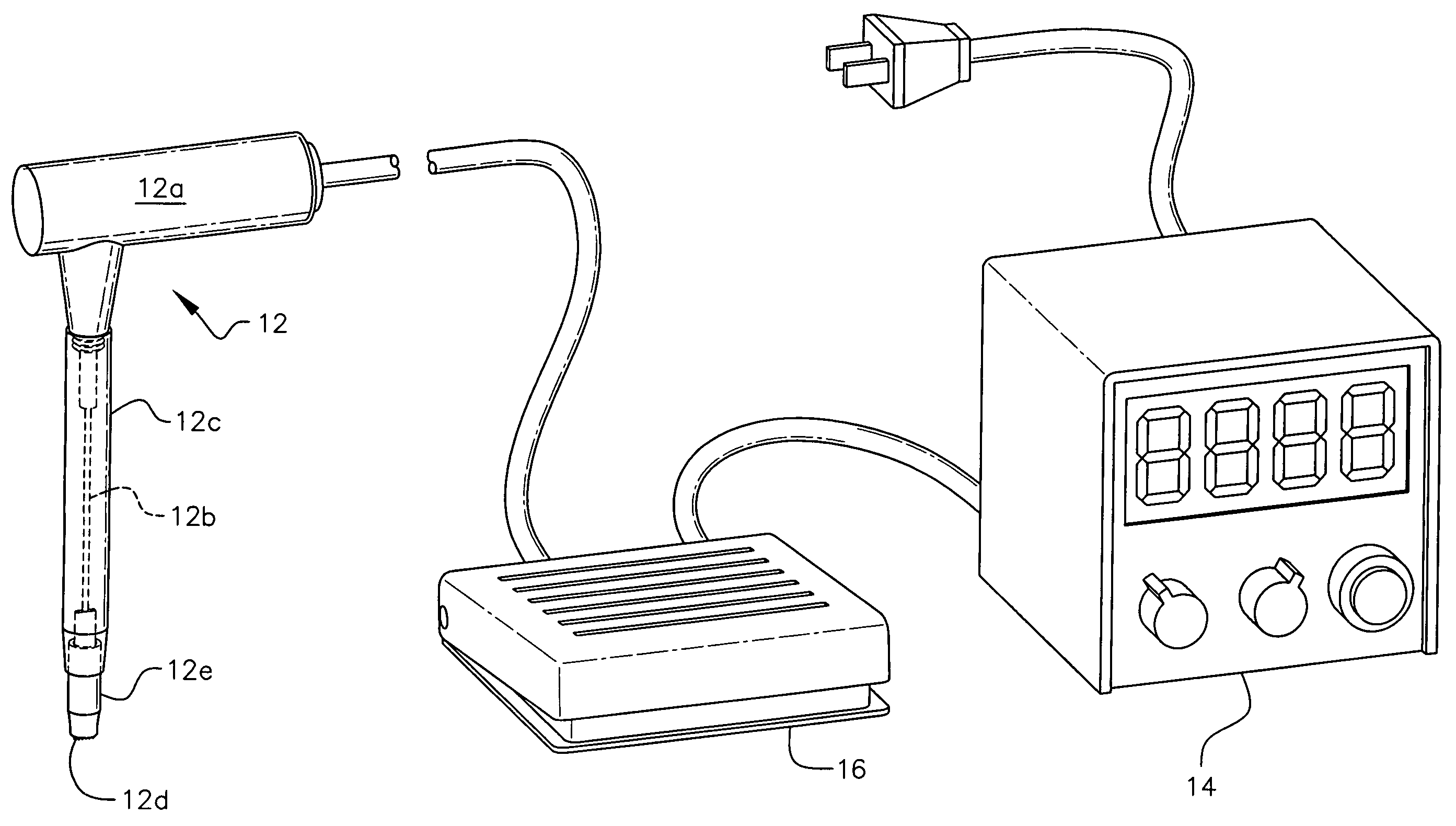

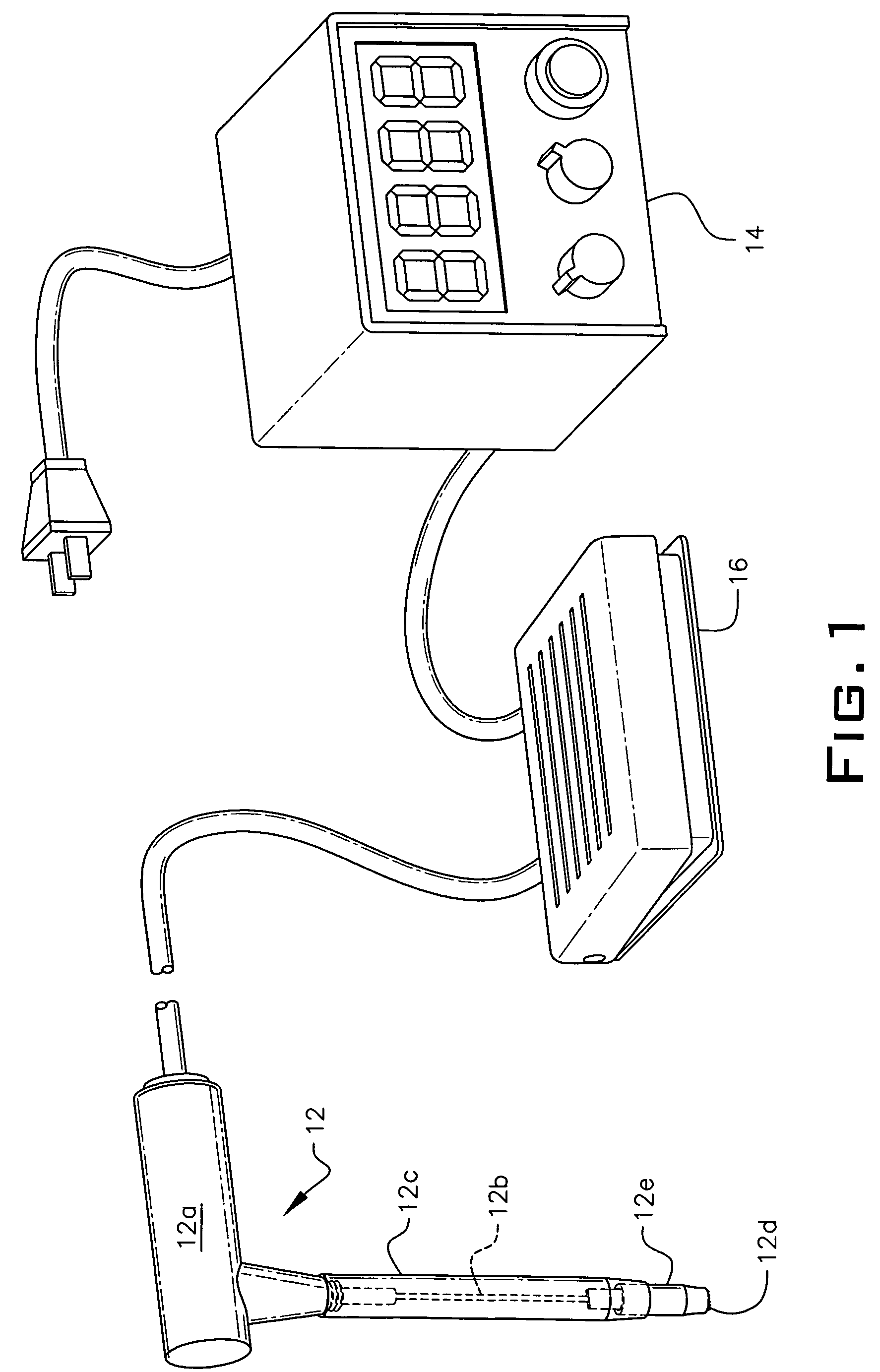

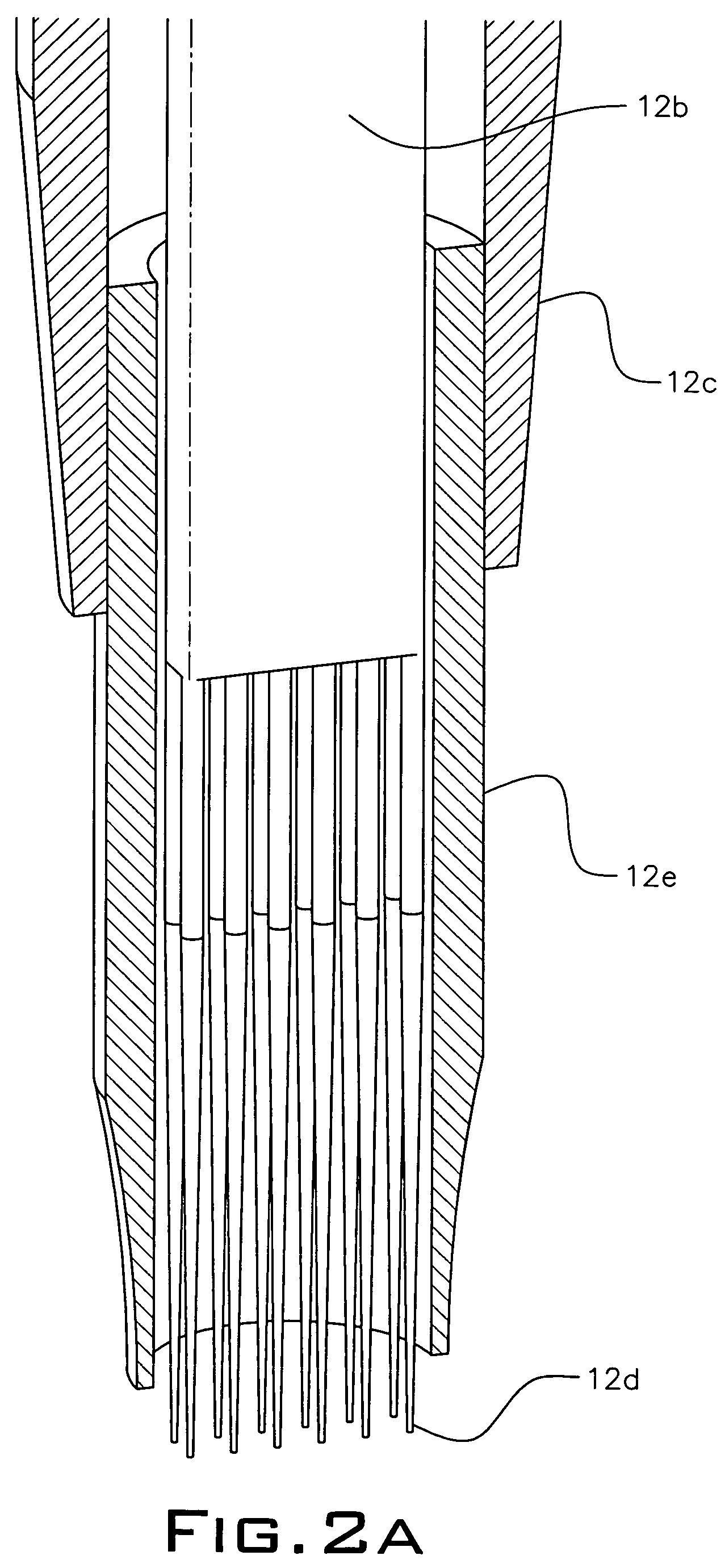

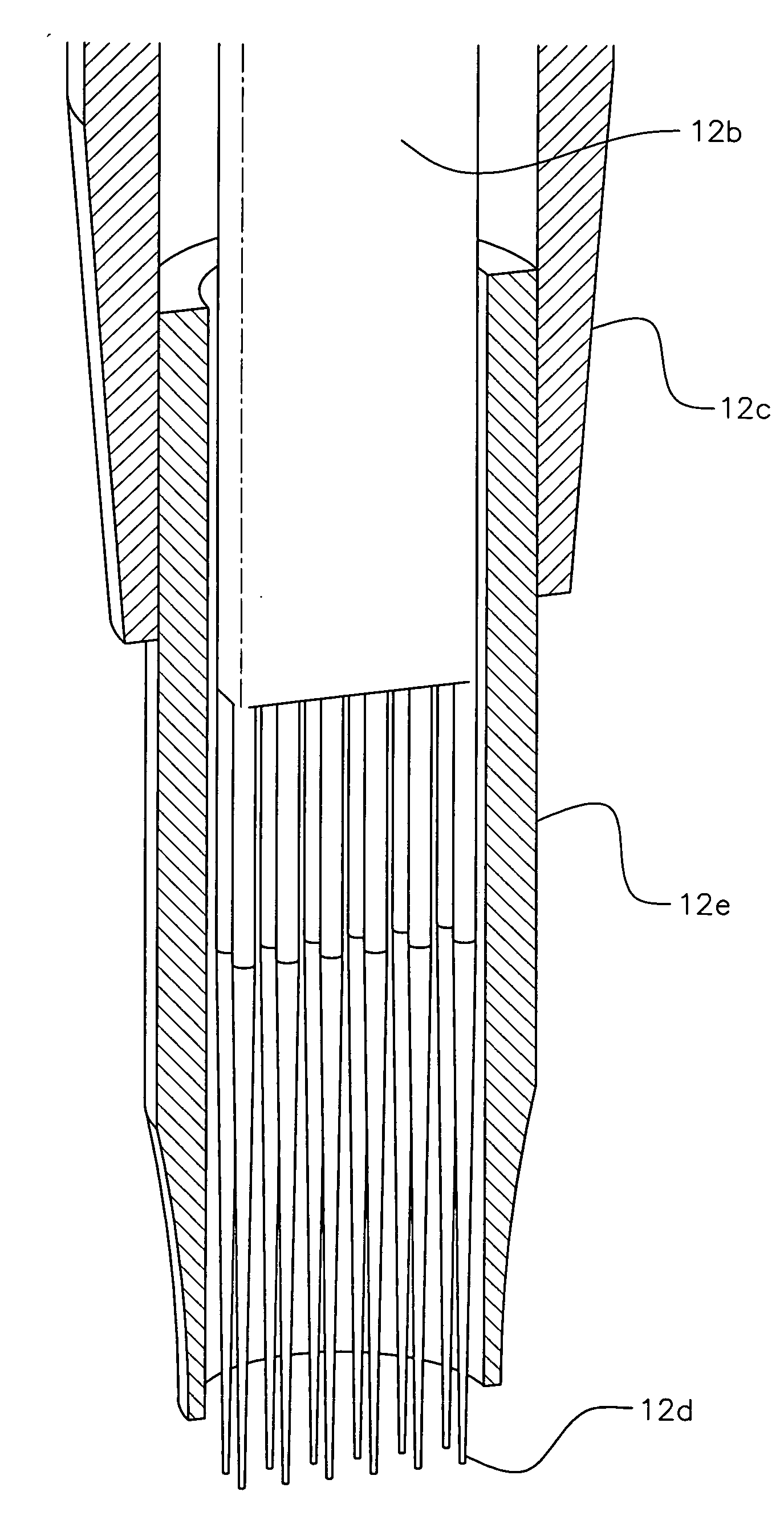

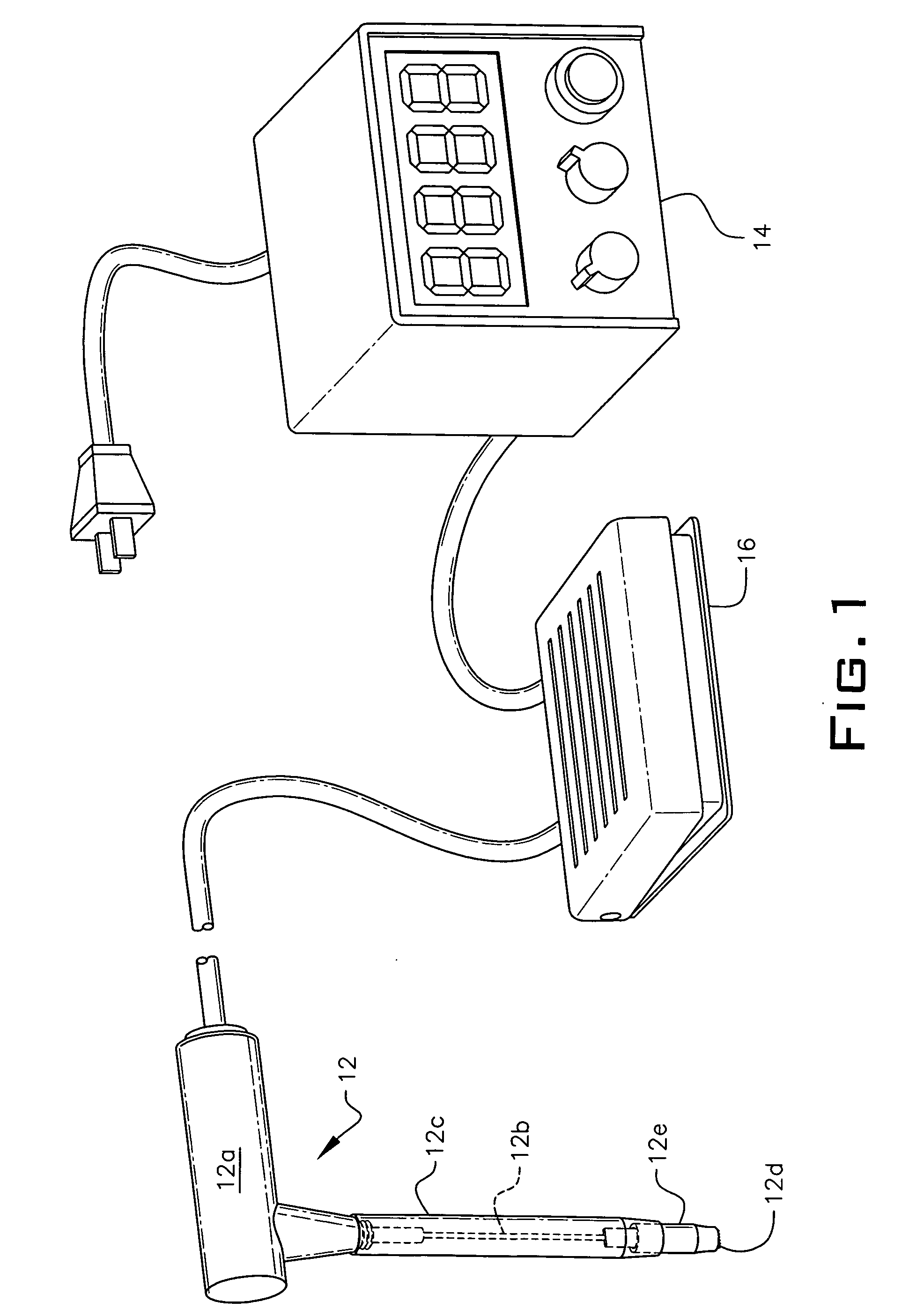

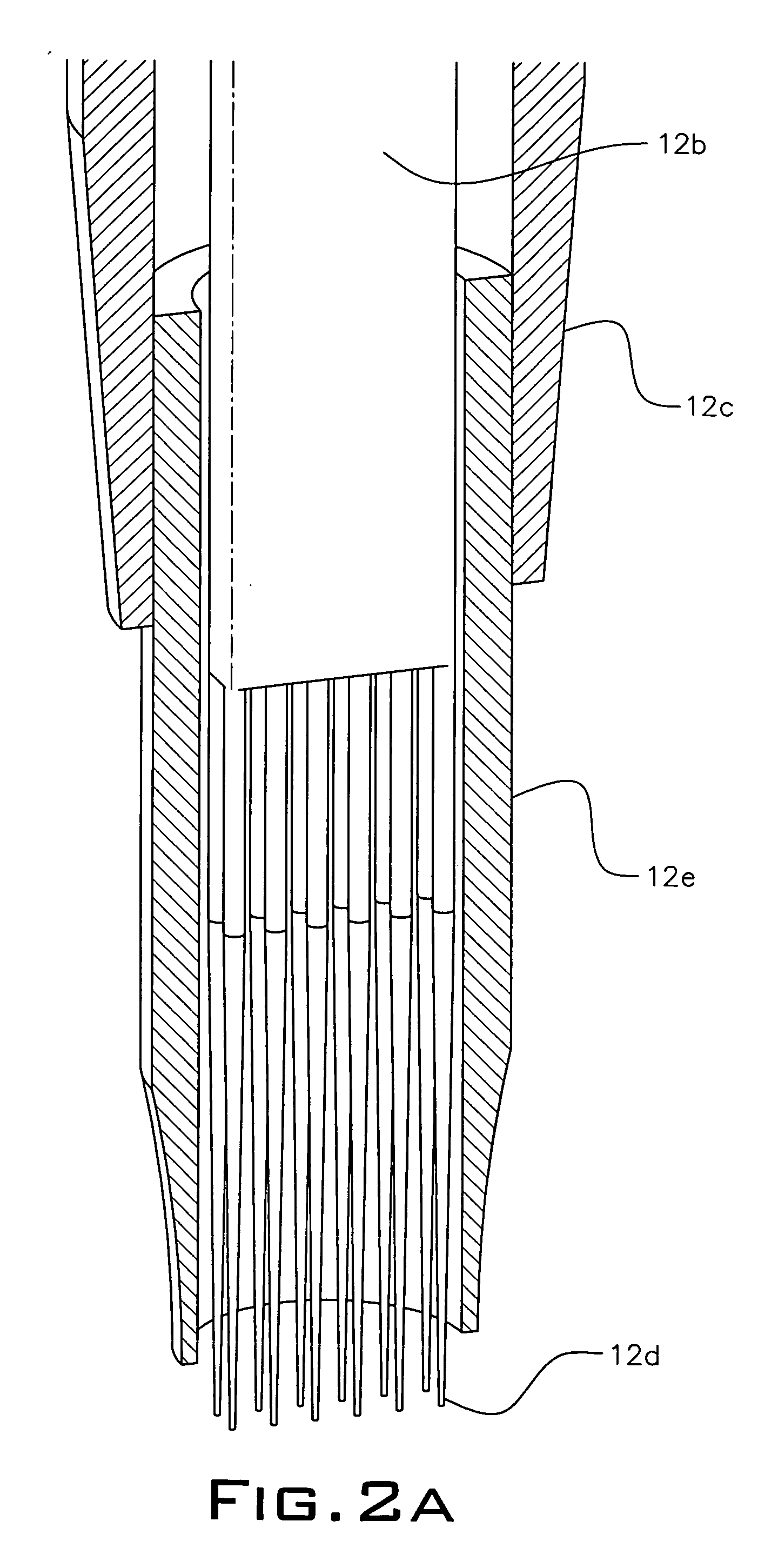

Skin rejuvination resurfacing method

ActiveUS7618429B2Eliminated or greatly reduced the wrinkle, scar or textural abnormalityWrinkled evenlySurgical needlesNon-surgical orthopedic devicesBiomedical engineering

Owner:INVASIX

Skin rejuvination resurfacing method

ActiveUS20070149991A1Eliminated or greatly reduced the wrinkle, scar or textural abnormalityWrinkled evenlySurgical needlesNon-surgical orthopedic devicesTissue skin

Owner:INVASIX

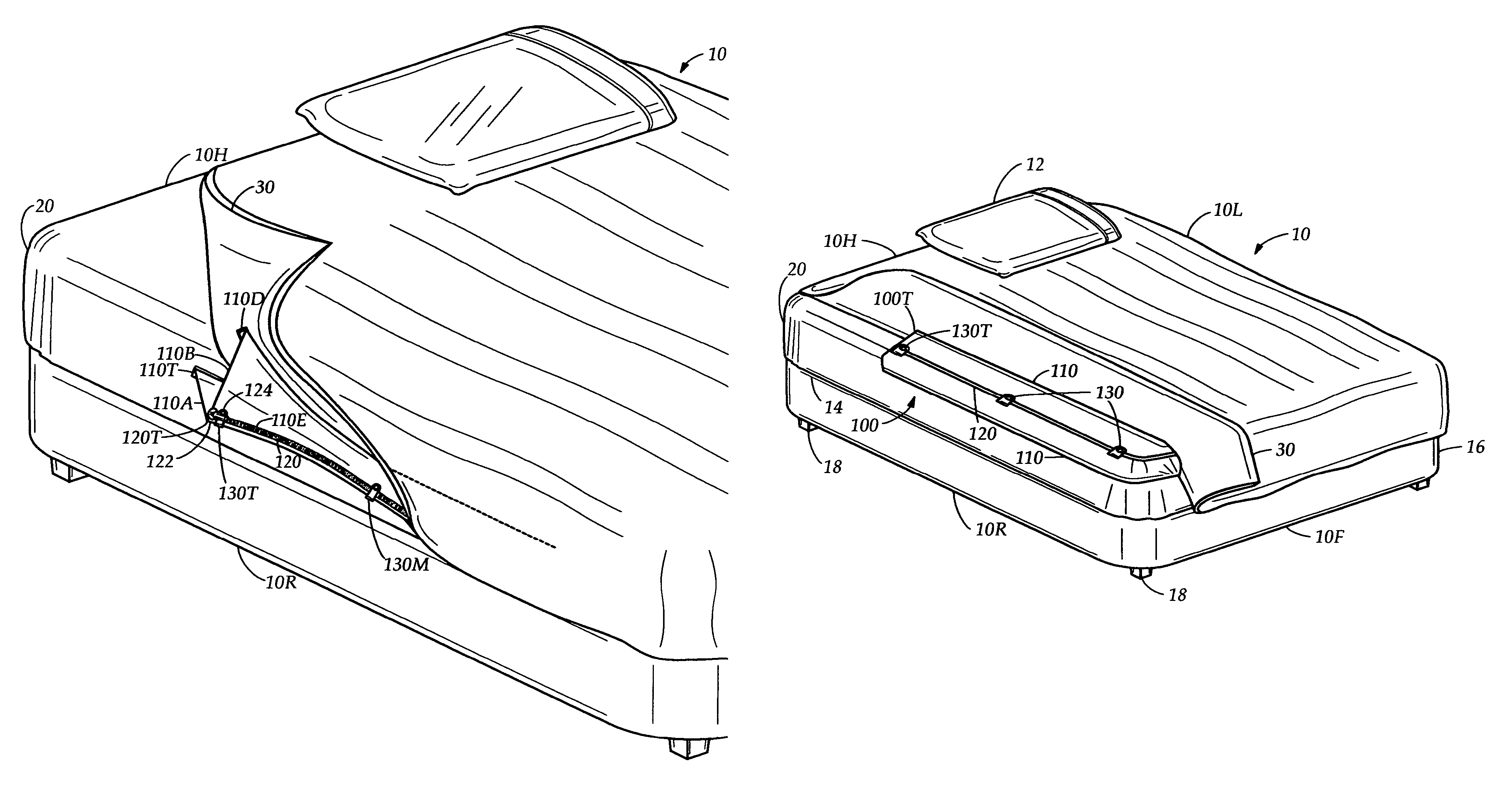

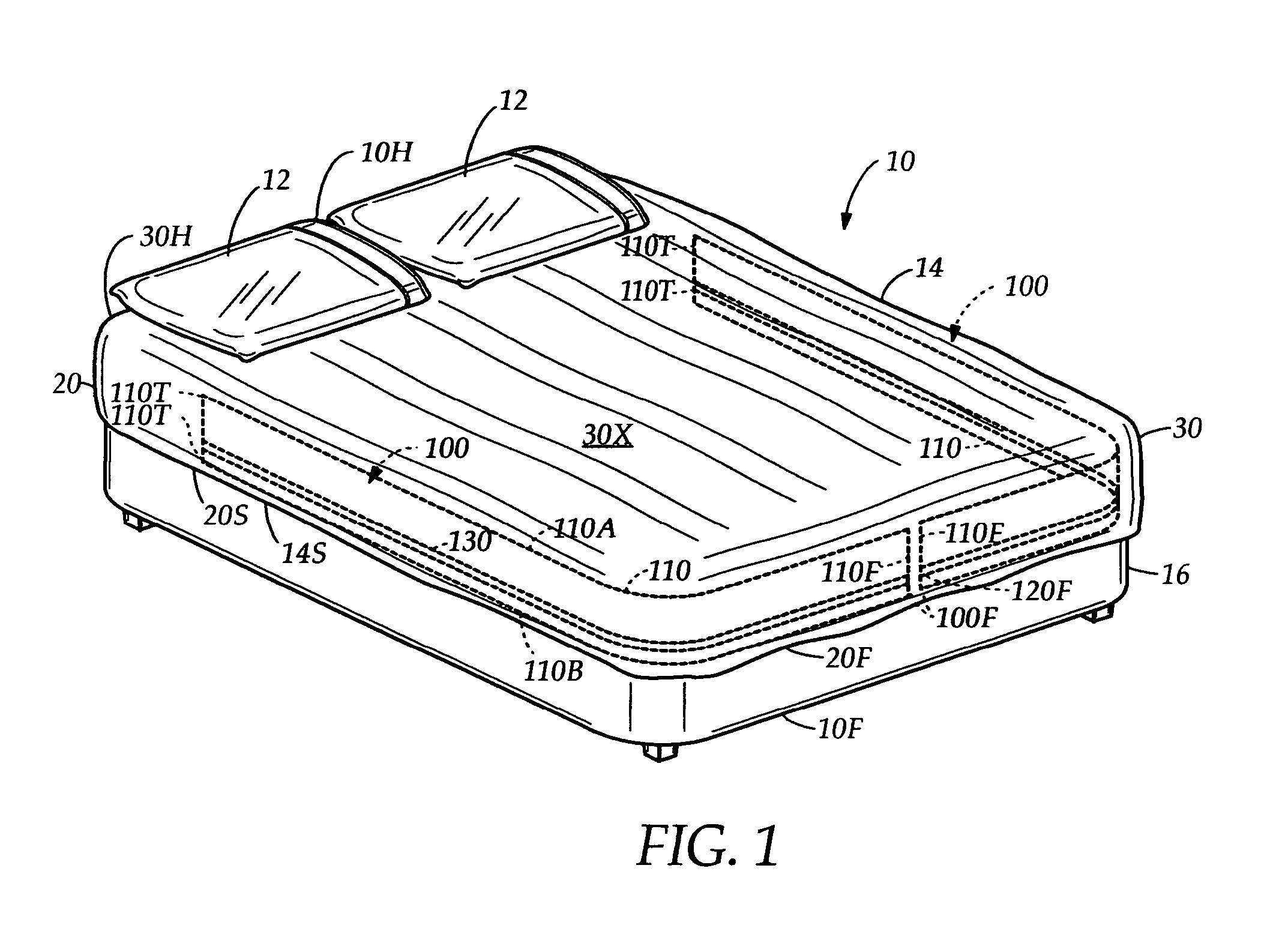

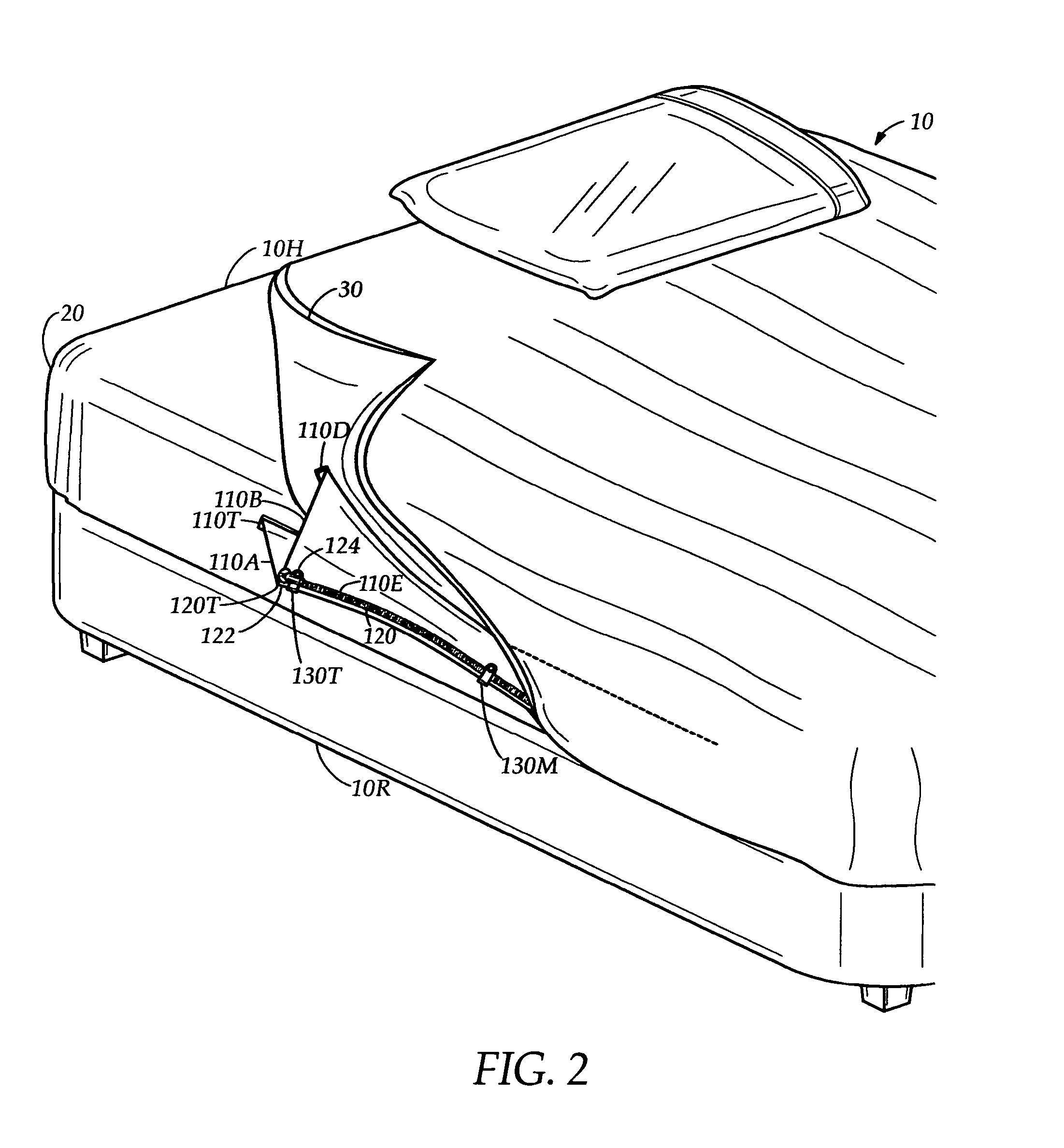

Bed sheet attachment system

A bed sheet attachment system with a pair of expansion panel assemblies that attaches a top cover to a bottom sheet by a plurality of panel strips connected by a plurality of fastener strips. The fastener strips are prevented from opening during sleep by a plurality of snap tabs. The plurality of panel strips provides increased cubic capacity between the top cover and bottom sheet for the sleeper to slip into and move within the bed. The plurality of snap tabs allows the panel strips to be separated at discrete lengths to accommodate the sleeper's needs and desires for the arrangement of the top cover during sleep. The bed sheet attachment system simplifies the daily making of the bed by maintaining the proper position of the top cover during sleep so that the user merely smoothes out the wrinkles on the top cover upon arising.

Owner:GEORGATOS NAPOLEON

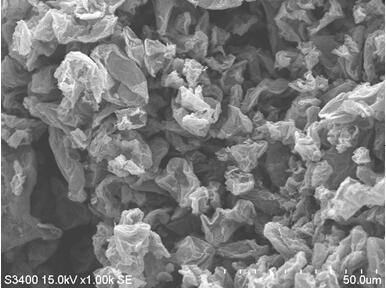

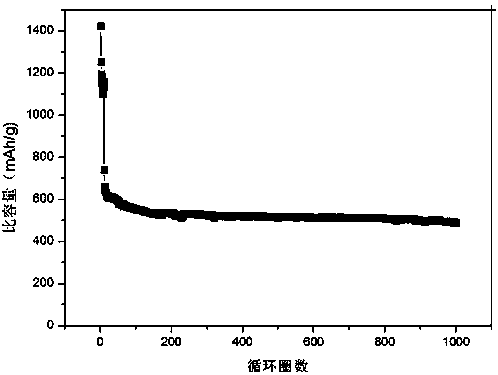

Preparation method and application of metal-loaded nitrogen-doped wrinkled graphene

PendingCN111072018AChange the electrochemical performanceEvenly dopedPhysical/chemical process catalystsOrganic compound preparationPhysical chemistryElectrochemistry

The invention discloses a preparation method and application of metal-loaded nitrogen-doped wrinkled graphene. Graphene oxide, ethylenediamine-terminated polyvinylamine and corresponding metal salt are used as raw materials. The preparation method comprises the following steps: dispersing graphene oxide into a certain solvent to form a solution A; preparing an ethylenediamine-terminated polyvinylamine solution with a certain concentration, adding a certain amount of a metal salt into the solution to form a solution B, mixing and stirring the solution A and the solution B, carrying out a hydrothermal reaction in a hydrothermal reaction kettle, collecting a solid after cooling, washing the solid, and drying the solid to obtain the final product. The experimental process is simple, the operability is high, and industrial popularization is facilitated; the prepared metal-loaded nitrogen-doped wrinkled graphene has the advantages of large specific surface area, a large number of wrinkles and pores, good structure retentivity, uniform nitrogen doping and uniform metal loading, greatly changes the catalytic and electrochemical properties of graphene, and widens the application of graphenein the fields of catalysis and energy storage.

Owner:JIANGSU UNIV OF TECH

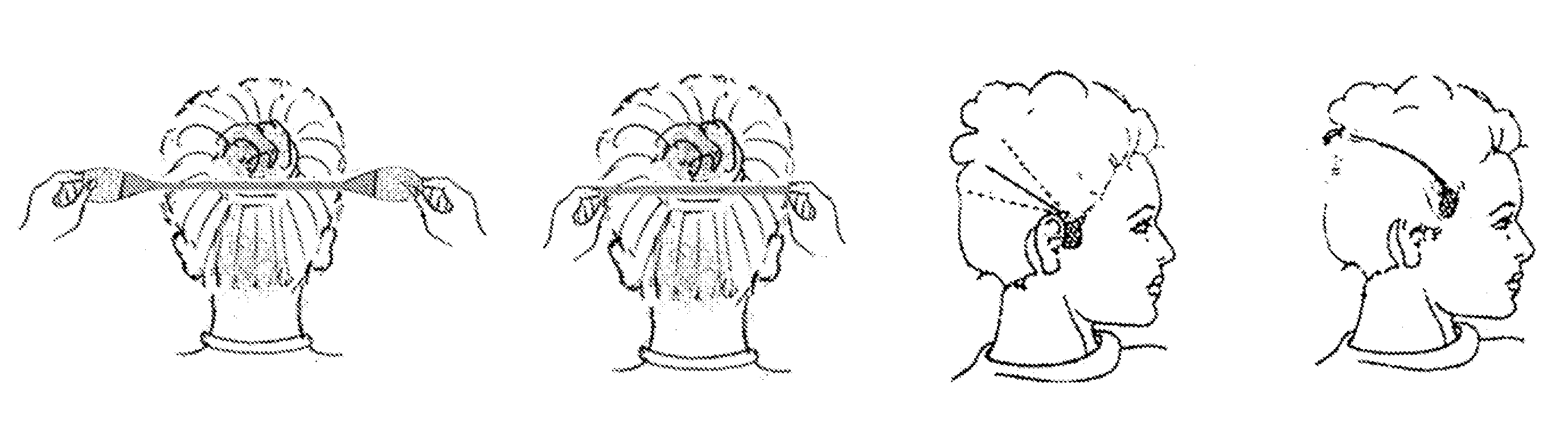

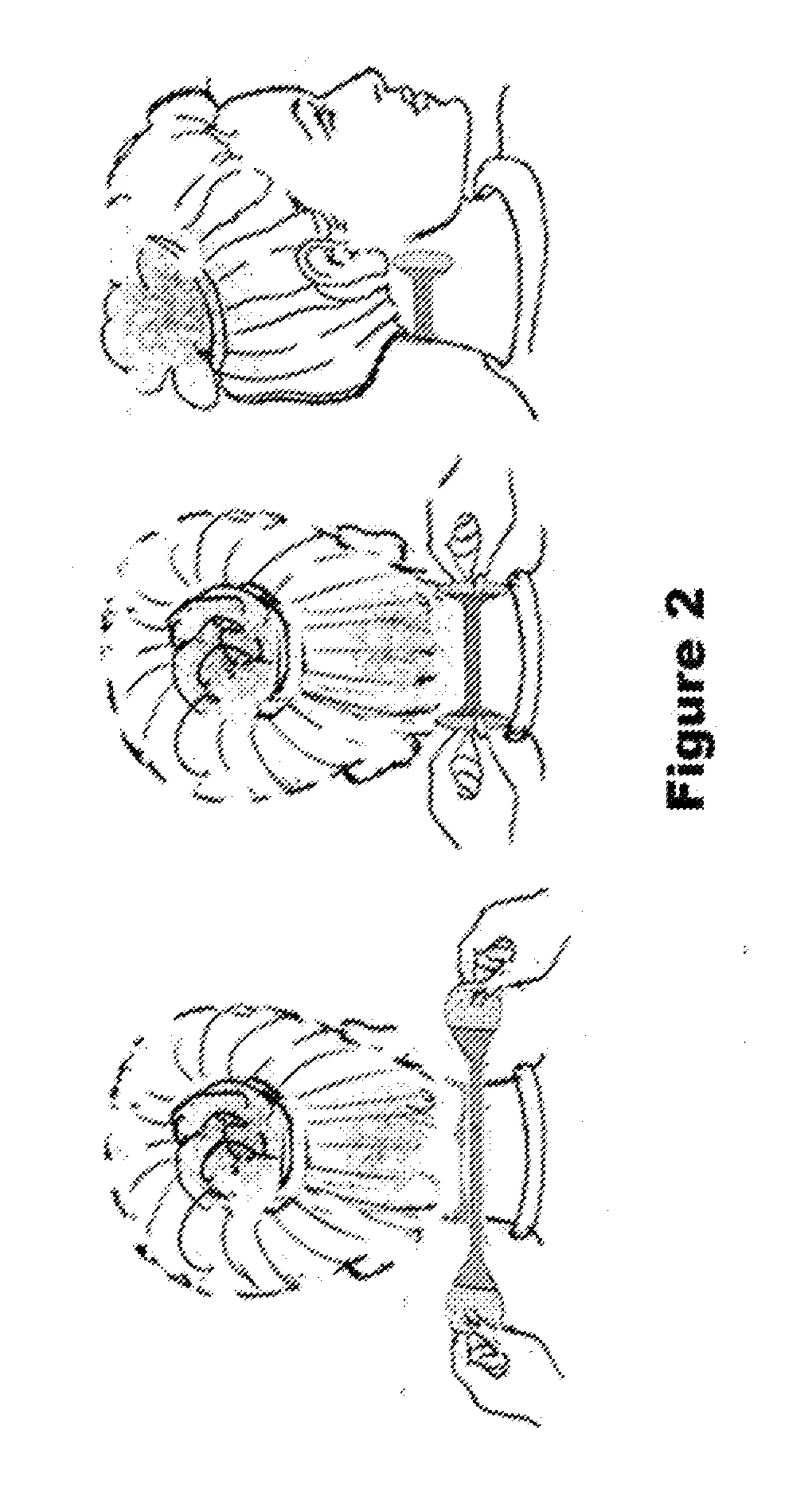

Face lifting device for face and neck

InactiveUS20140243886A1Highly effectiveWrinkled evenlyHead bandagesNeck bandagesEngineeringFace lifting

Provided herein is a face lifting, device to be worn by a user to lift sagging skin or smooth wrinkles of the face or neck; the device comprising a singular construction of a stretchable portion and an adhesive portion at each end of the stretchable portion. Also, provided herein is a kit for lifting sagging skin or smoothing wrinkles of the face or neck; the kit comprising: a face lifting device comprising a singular construction of a stretchable portion and an adhesive portion at each end of the stretchable portion, wherein the adhesive portion is adapted for attachment to the user's facial eye area; and a face lifting device comprising a singular construction of a stretchable portion and an adhesive portion at each end of the stretchable portion, wherein the adhesive portion is adapted for attachment to the user's neck or jaw area.

Owner:COSMESEARCH

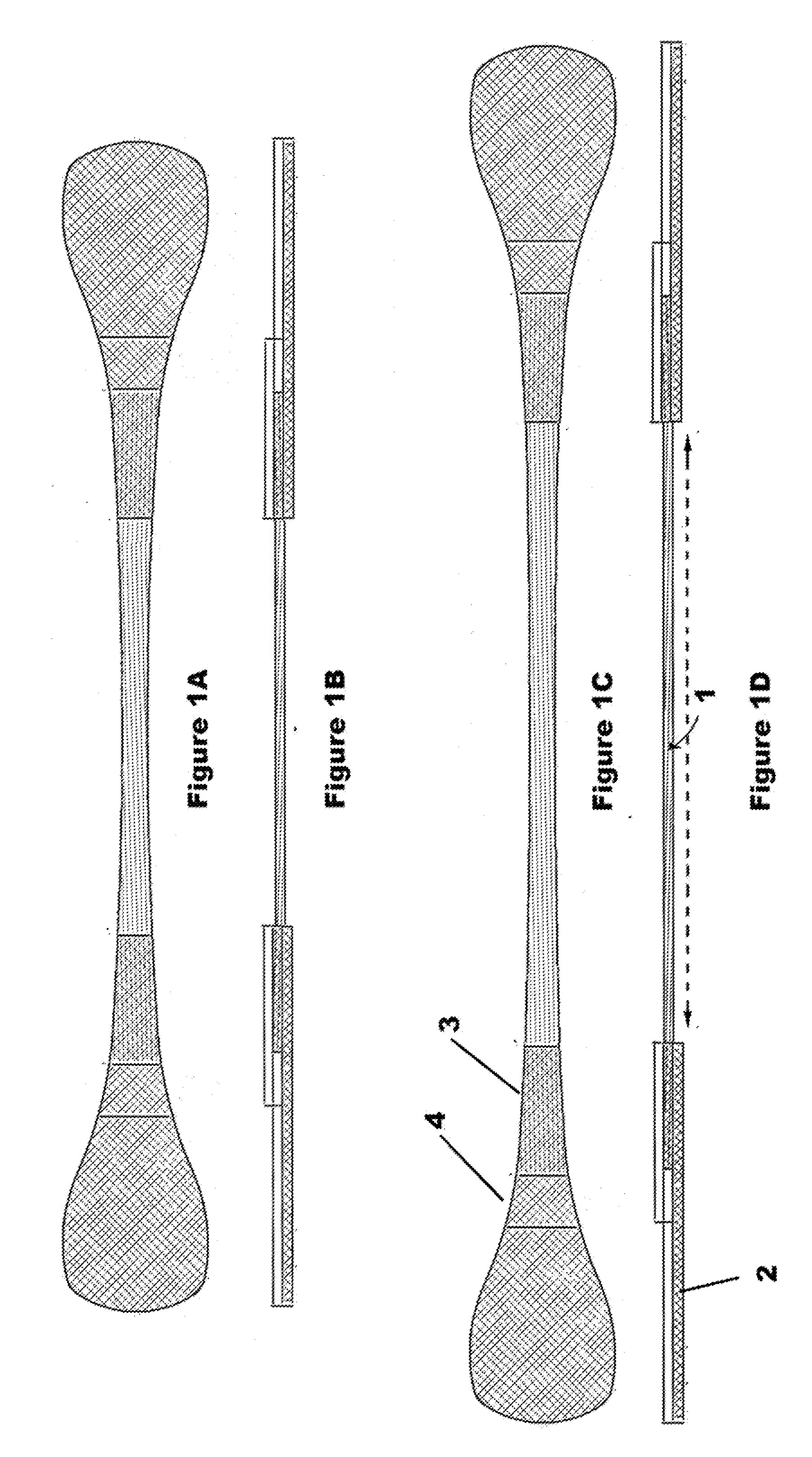

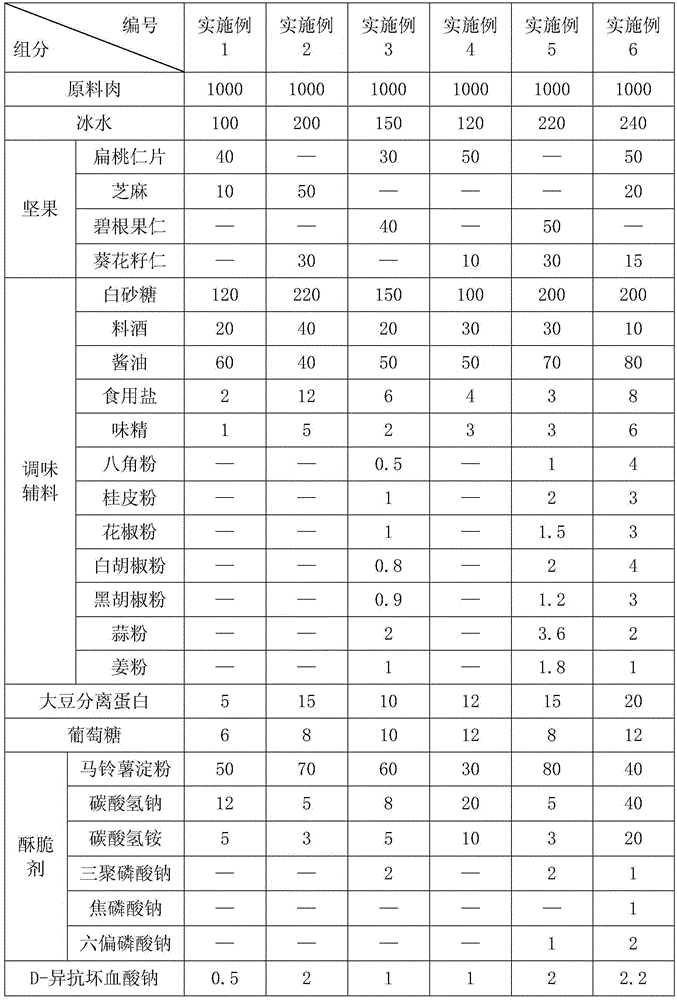

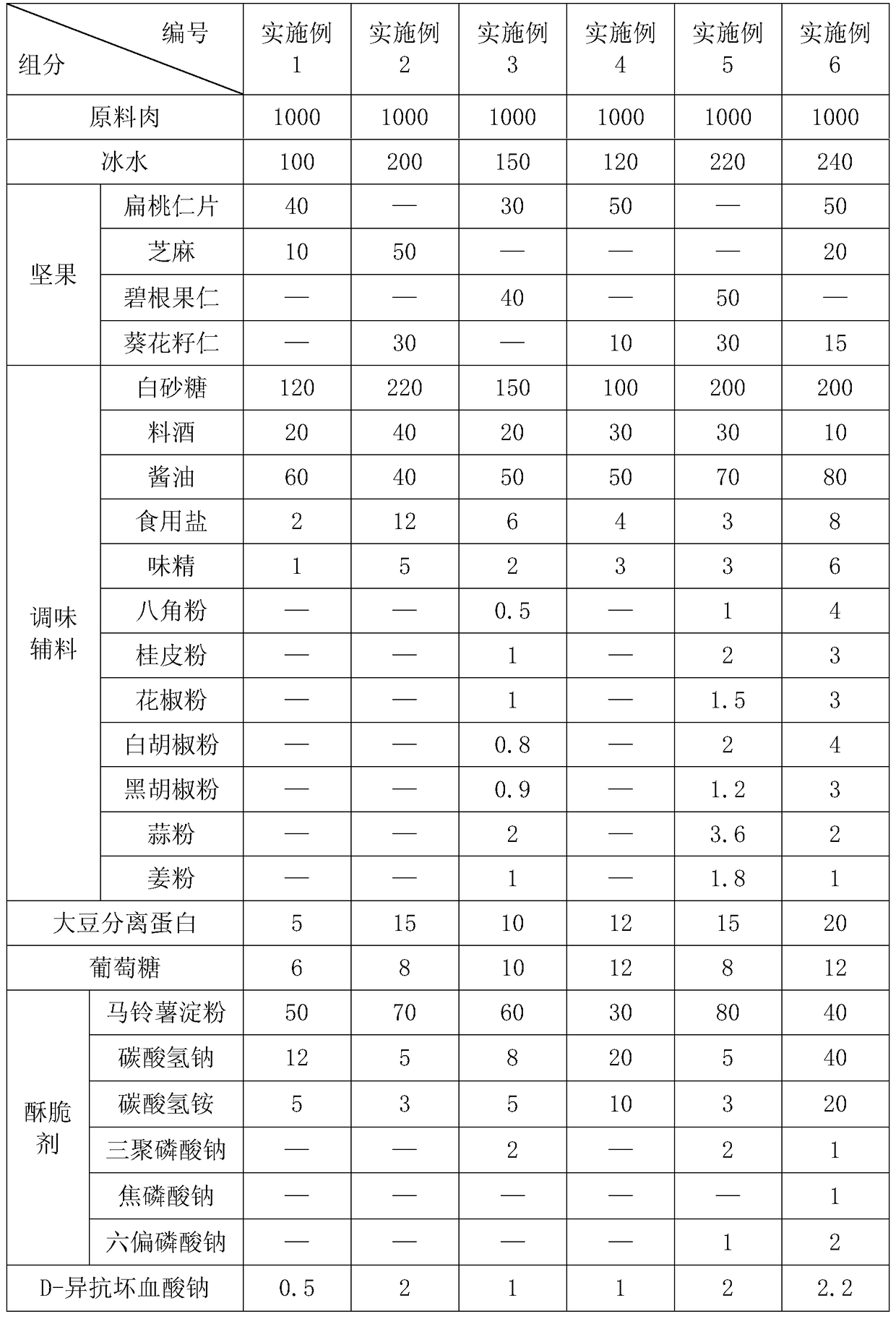

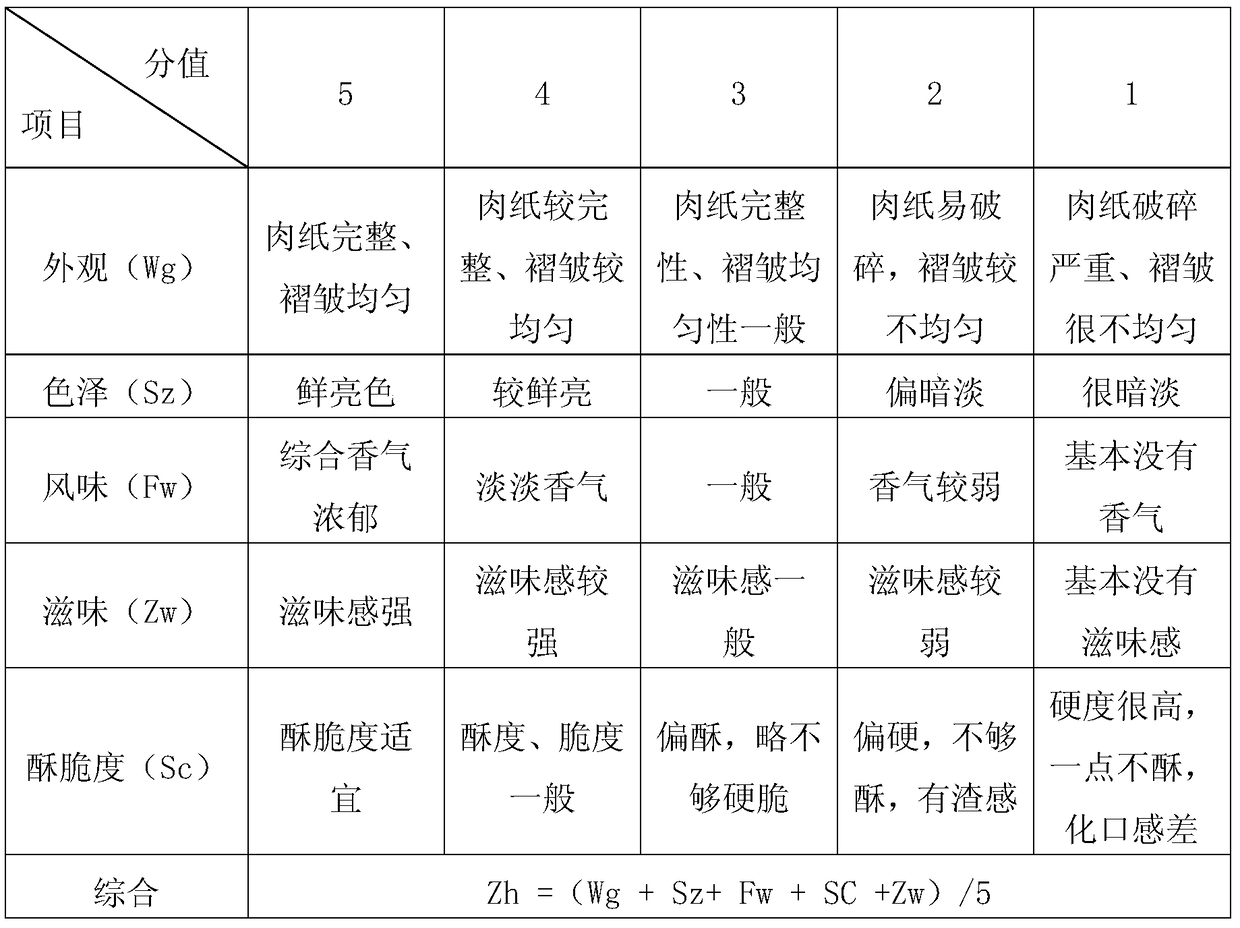

Pigment free, transparent, thin and crisp meat paper and processing method thereof

The present invention discloses a pigment free, transparent, thin and crisp meat paper and a processing method thereof. The processing method comprises the following processing steps: 1) weighing raw materials of raw material meat, iced water, nuts, auxiliary materials, isolated soy proteins, glucose, crisp agent, and D-sodium erythorbate in proportion; 2) mixing the above raw materials evenly and pickling the mixed raw materials to obtain a filling material; 3) pouring the filling into a mold to be compacted tightly into a block meat base material and quickly freezing the meat base material; 4) placing the frozen meat base material under a temperature of 10-20 DEG C for storage and when the center temperature is raised to -3 to -5 DEG C, slicing the meat base material into thin meat slice using a slice cutter; 5) firstly conducting a low-temperature drying for the thin meat slice, then conducting a high temperature drying and curing of the low-temperature dried thin meat slice, air-blowing the dried thin meat slice after curing, and cooling the thin meat slice into a room temperature to obtain the transparent, thin and crisp meat paper; 6) placing the transparent and thin meat paper in a packaging workshop with a relative humidity less than 40% and packaging and storing the thin meat paper. The obtained meat paper has a complete appearance, and is even in folds, not easily broken, strong in sense, and transparent, crisp and so on.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

Double-layer elastic anti-crumple jacquard fabric and manufacturing technology thereof

InactiveCN108642646ASimple processReduce manufacturing costHeating/cooling textile fabricsDyeing processYarnManufacturing technology

The invention provides a double-layer elastic anti-crumple jacquard fabric and belongs to the technical field of textile fabric production and processing. The fabric includes, by mass, 55%-65% of warpand 35%-45% of weft, wherein the warp adopts two kinds of 75D-100D low stretch yarn different in color, and the weft adopts two kinds of 75D-100D high stretch yarn and 75D-100D dacron cation silk which are different in color. The fabric is formed by weaving double-layer jacquard texture, and radial straight creases and a jacquard pattern are formed on the front surface of the fabric. The manufacturing technology of the double-layer elastic anti-crumple jacquard fabric includes the following steps of weaving and manufacturing of gray fabric, adoption of cation dyes for dyeing, reduction clearing, dewatering, shaping by a softening agent, examination, reeling and storage in a warehouse. A traditional crumpling technology is abandoned, and the same crumpling effect is achieved, so that the technology processes are simplified, and the production cost is greatly reduced. The fabric is soft in hand feeling and has uniform creases which are not likely to fade, and the straight creases can last forever. The production technology processes are environmentally friendly and free of pollution, and the fabric is high-end and safe and has a great market prospect.

Owner:绍兴水乡纺织科技有限公司

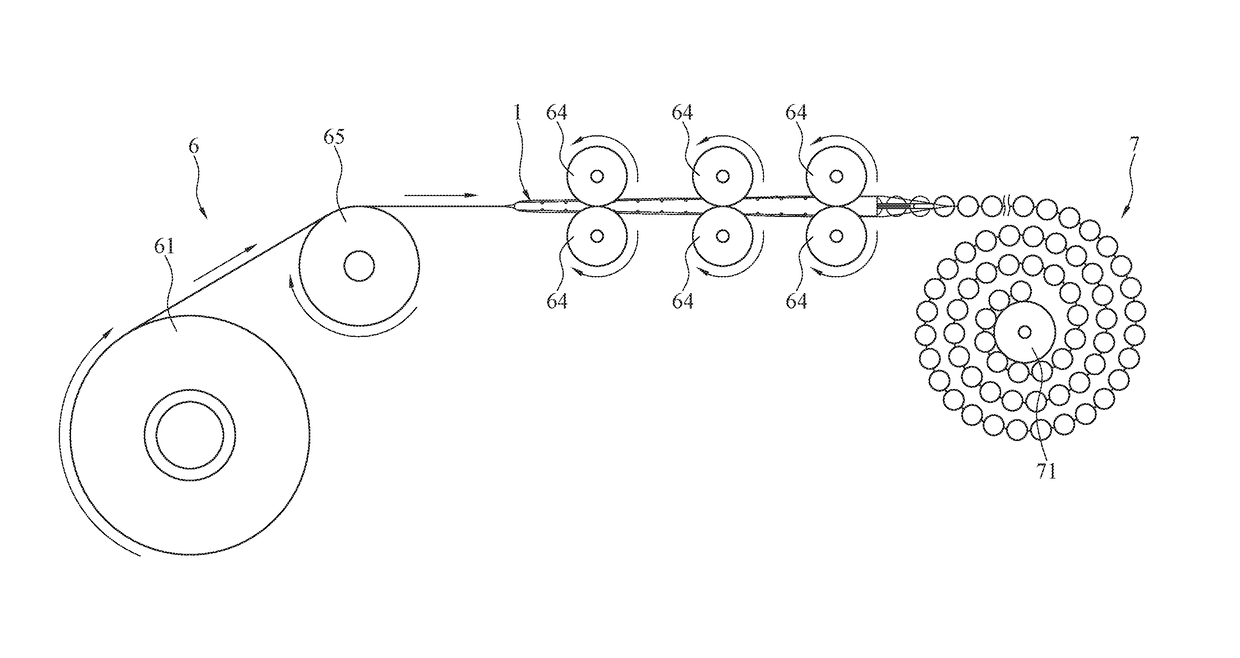

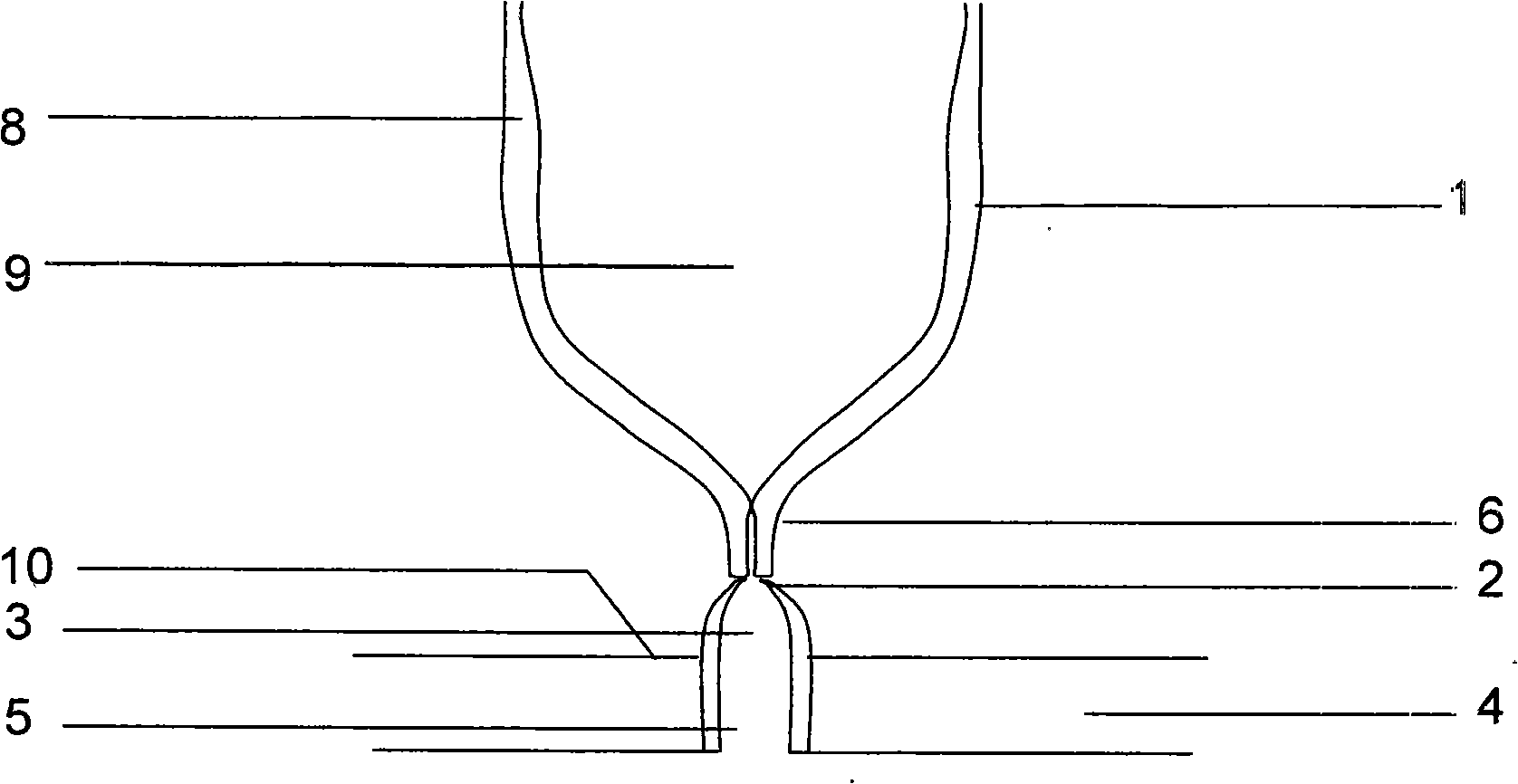

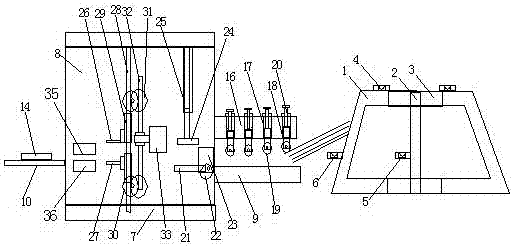

Inflating stick and processing machine

ActiveUS20180297729A1Speed up gas flowWrinkled evenlyPaper/cardboard articlesBag making operationsEngineeringMechanical engineering

An inflating stick and a processing machine are provided. The inflating stick includes a body, a link rod, a cutter, and one or more inflating tubes. A front end of the body includes a guiding segment with a cone structure. A rear end of the body includes a packing segment. The body includes a gas inlet formed on the packing segment, an internal chamber allowing gas to flow into through the gas inlet, and gas outlets formed on an outer wall of the body allowing gas to flow out. The packing segment includes a first locking structure and a second locking structure. The first locking structure and the second locking structure communicate with the gas inlet. The second locking structure is detachably fastened to the first locking structure. The link rod and the cutter are disposed in rear of the body. The inflating tube is connected to the gas inlet.

Owner:AIR BAG PACKING +1

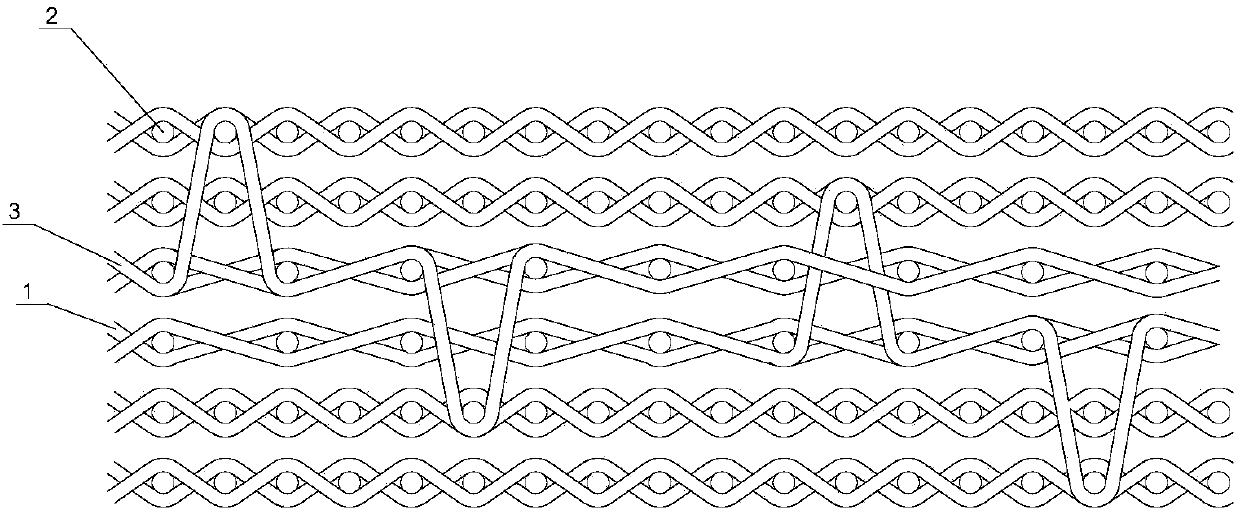

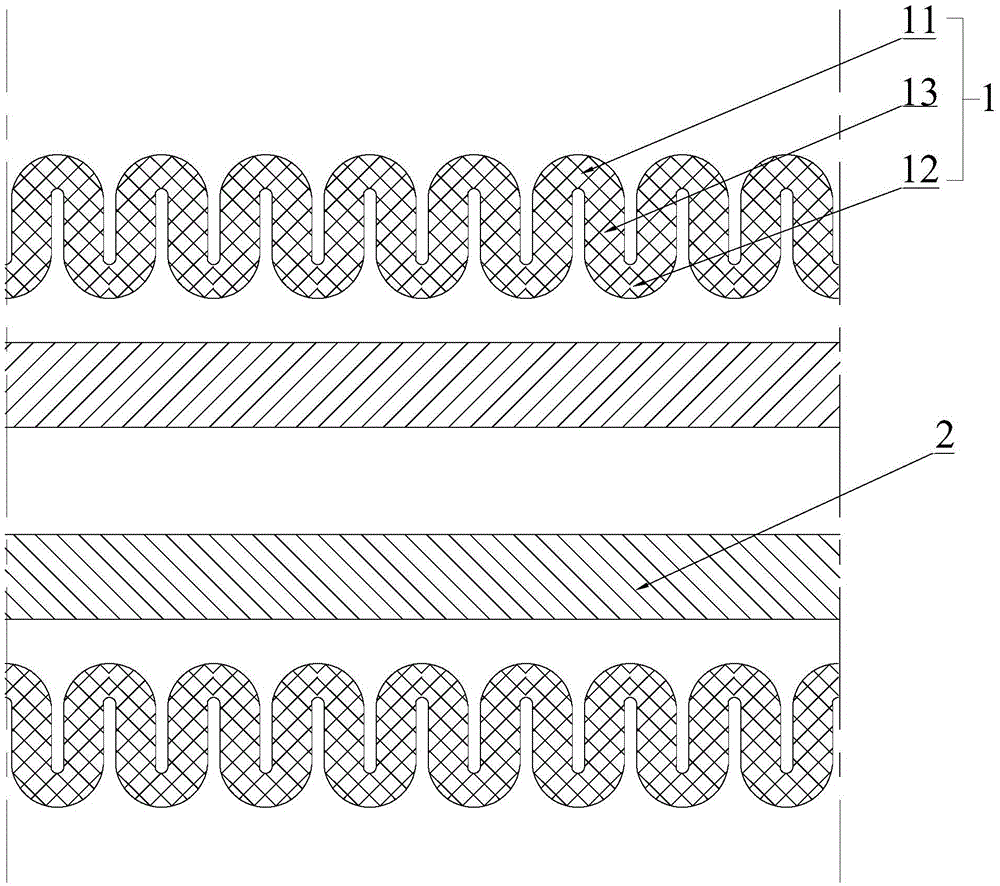

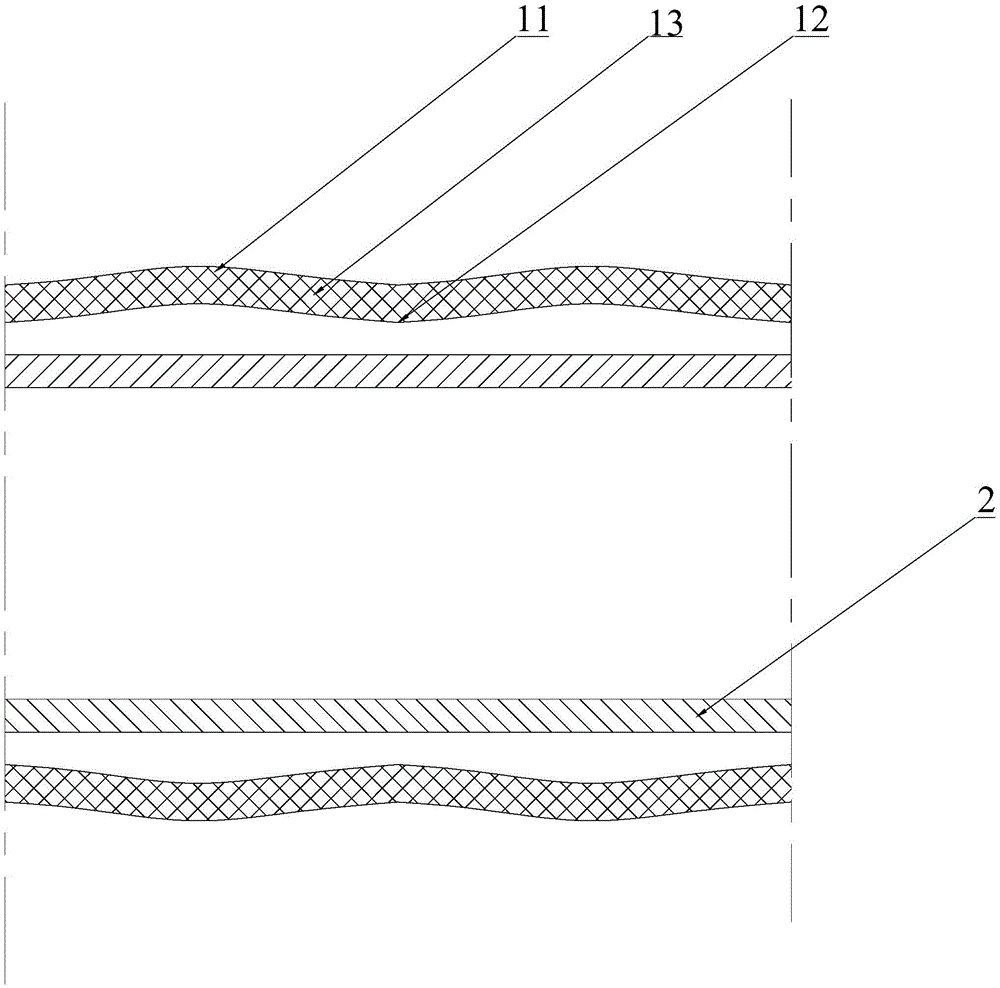

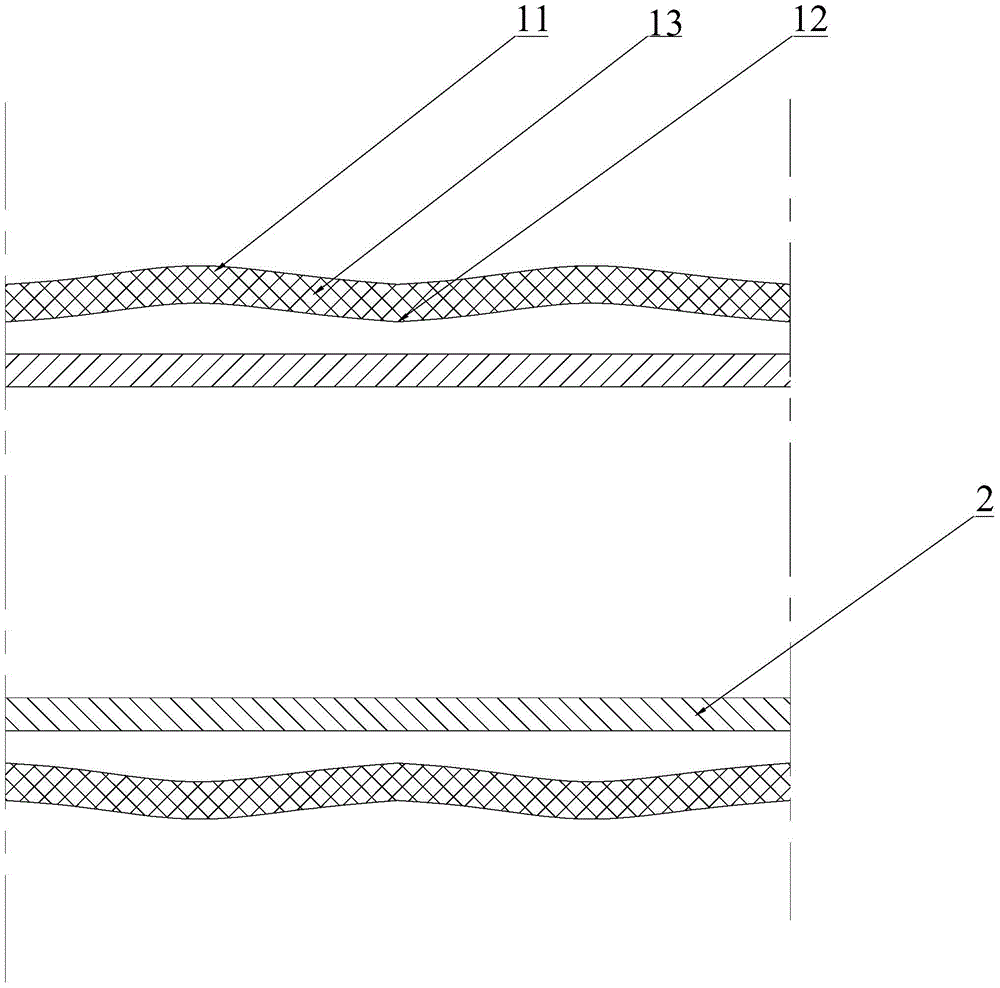

Multilayer cloth and manufacturing method thereof

InactiveCN107587229AEvenly distributedReasonable structureMulti-ply fabricsLiquid/gas/vapor textile treatmentEngineeringWeft yarn

The invention relates to multilayer cloth and a manufacturing method thereof. The multilayer cloth comprises multiple base cloth layers formed by weaving warp yarn and weft yarn, the base cloth layersare connected through connecting points, and the warp yarn of one base cloth layer bypasses the weft yarn of other base cloth layers and then is connected to form a structure serving as one connecting point. The warp yarn comprises weaving warp and connecting warp, the weaving warp is only woven in the local layer, and the connecting warp serves as the weaving warp of the layer where the connecting warp is located originally, is woven with the weft yarn of the layer where the connecting warp is located originally, bypasses the weft yarn of the other base cloth layers at the interval of multiple pieces of weft yarn, and then returns to the layer where the connecting warp is located originally again to connect the multiple base cloth layers together. According to the weaving method, the multilayer cloth is woven integrally, and the process is simple and reasonable.

Owner:稳健医疗用品(荆门)有限公司

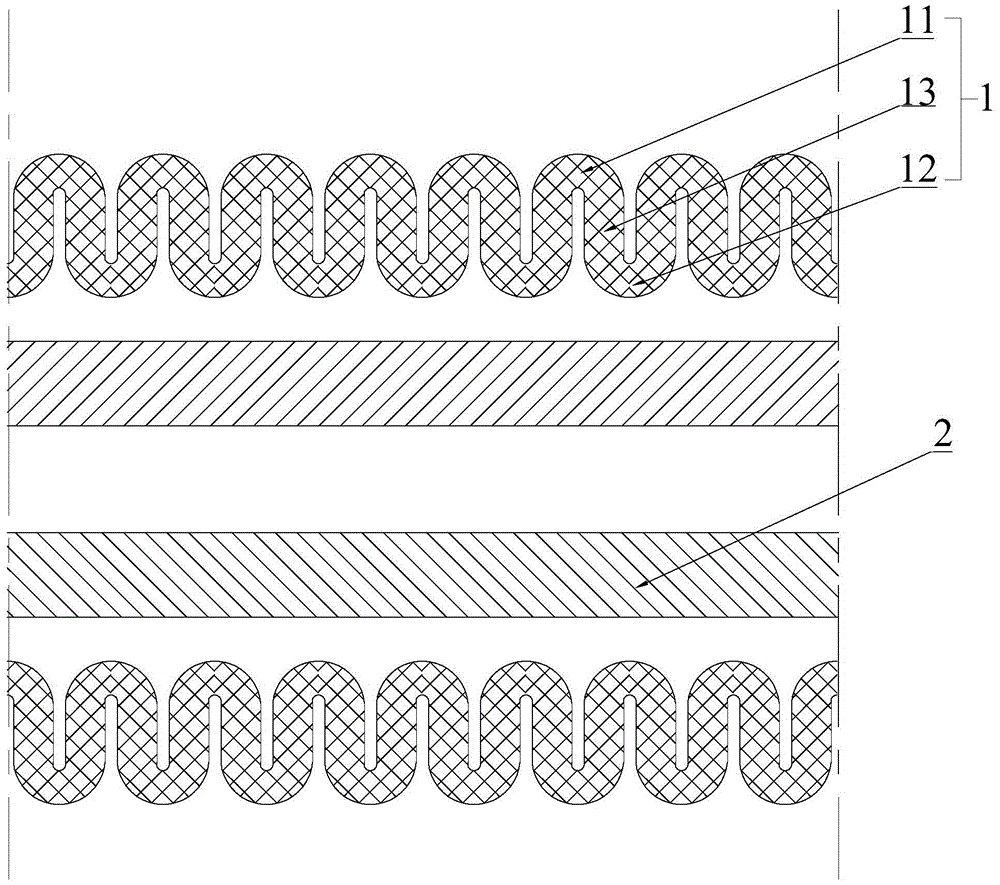

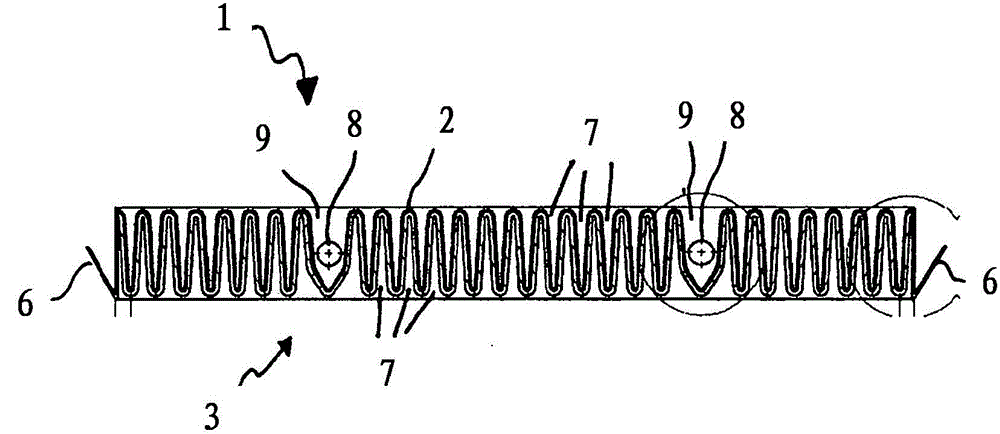

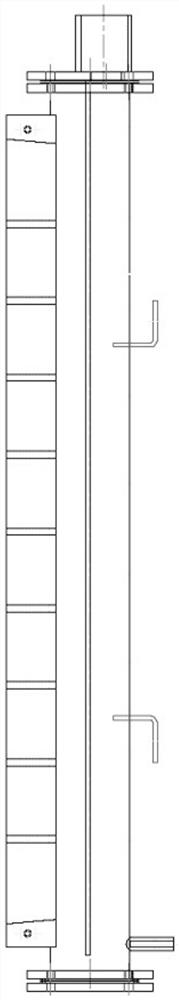

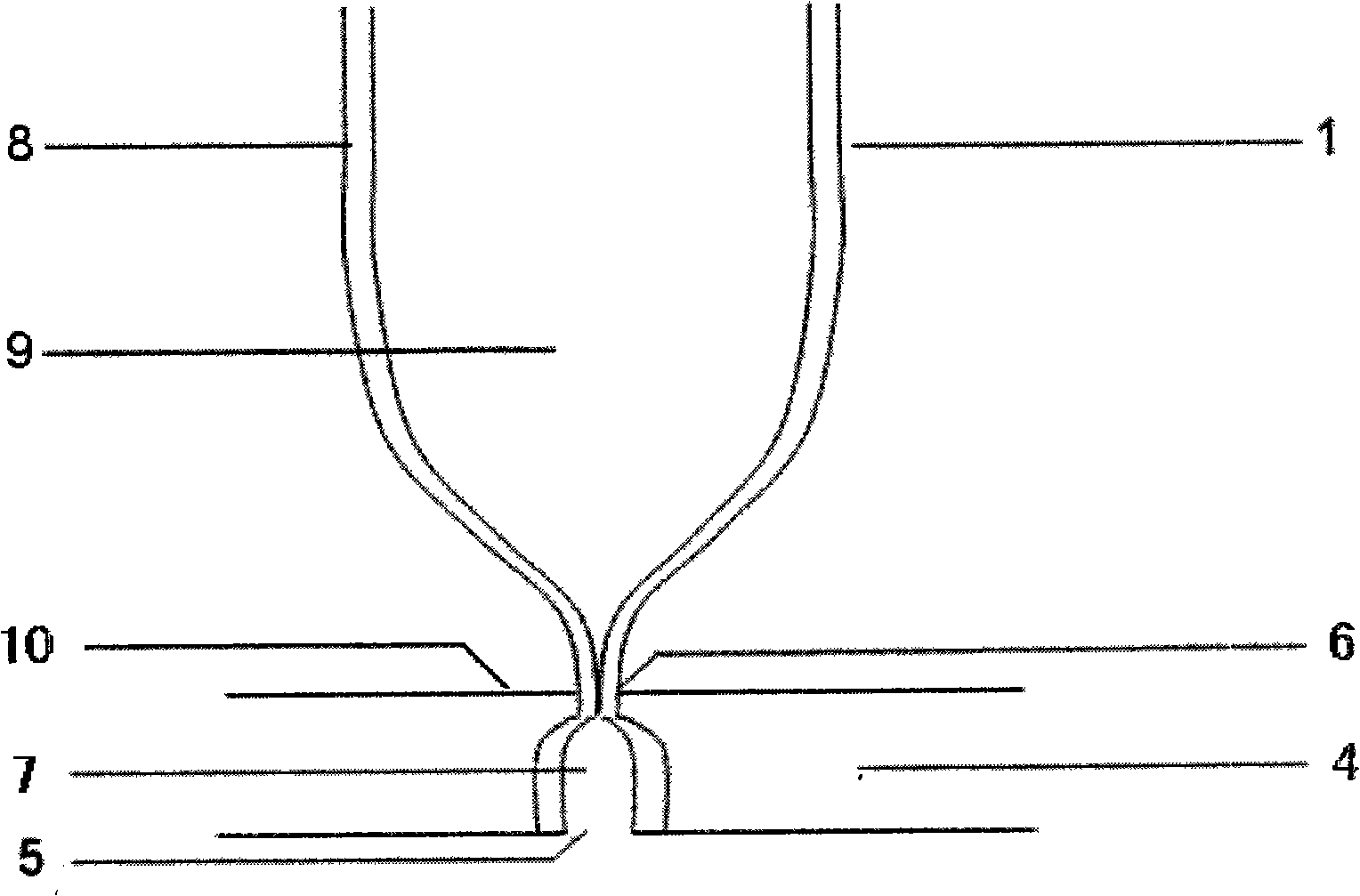

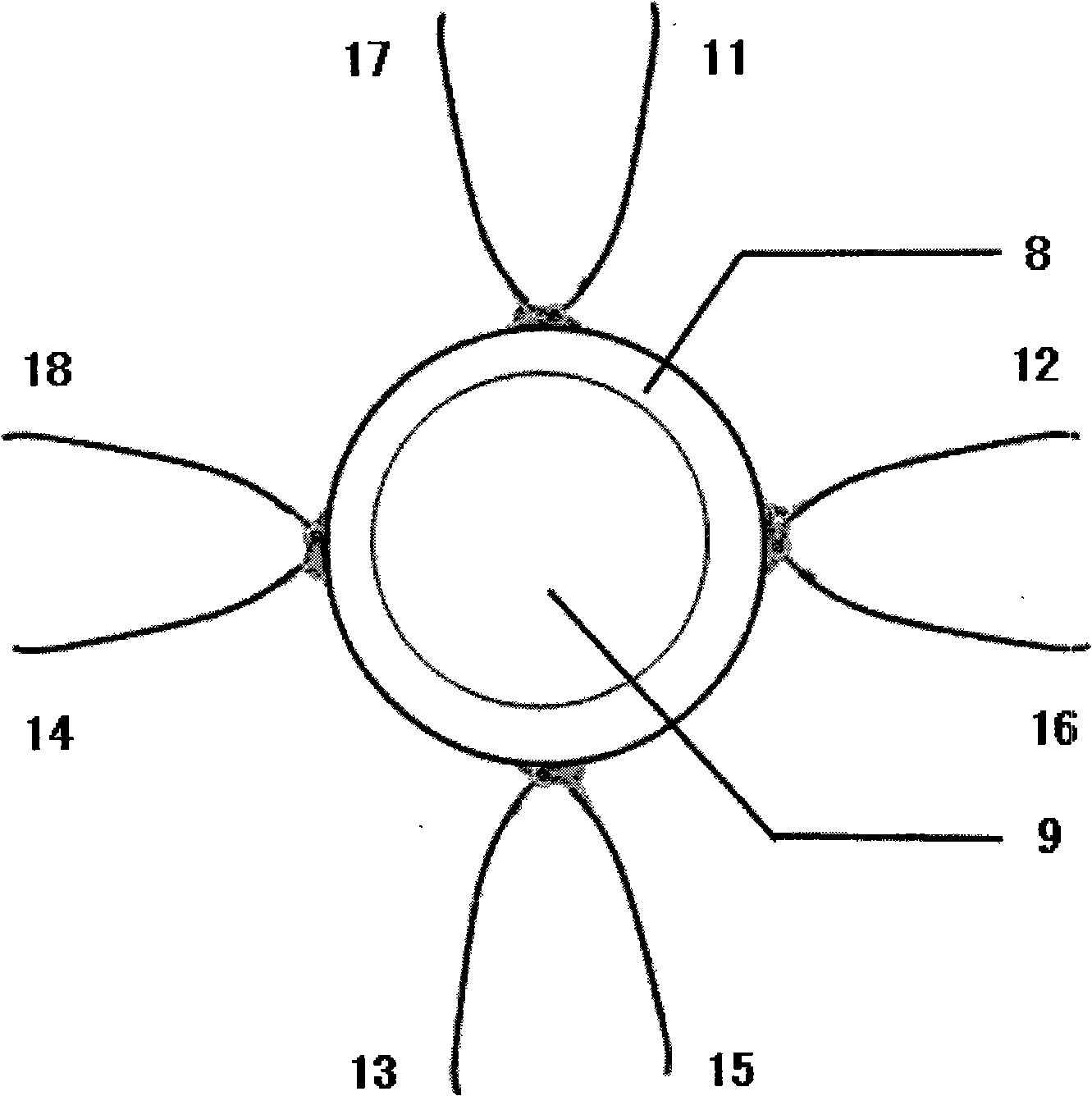

Pipe, pipe manufacturing method and stretchable water pipe

ActiveCN105465501AImprove structural strengthUniform shape deformationPipeline expansion-compensationFlexible pipesWrinkle skinUltimate tensile strength

The invention discloses a pipe, a pipe manufacturing method and a stretchable water pipe. The pipe is stretchable and uniform in structure and will not generate wrinkling angles when stretching or retracting. According to the technical scheme, the pipe is characterized by comprising a pipe body capable of stretching and retracting in the length direction, the pipe wall extends outwards integrally to form a plurality of flexible convex rings when the pipe body is in the natural retracting state, the pipe wall extends inwards integrally to form a plurality of flexible concave rings when the pipe body is in the natural retracting state, and the pipe body of the structure can deform uniformly; during retracting, the outer wall of the pipe is composed of outer walls of the multiple flexible convex rings, the inner wall of the pipe is composed of inner walls of the multiple flexible concave rings, and the shapes are uniform; due to the fact that no irregular wrinkles exist and no sharp wrinkle angles exist, materials inside and outside the pipe or skin will not be scratched; and during stretching, the pipe is in a similar pipe shape, in other words, the inner wall and the outer wall are of the micro wavy structures, the inner and outer wall stress of the pipe can be effectively buffered, the pipe has the good structural strength and can achieve uniform shape deformation, and the good application market is achieved.

Owner:NINGBO FENGYUAN IMPORT & EXPORT CO LTD

Methods for protecting skin and/or promoting wound healing

ActiveUS20180064771A1High expressionPromote wound healingCosmetic preparationsToilet preparationsWound healingMedicine

A method for at least one of protecting skin and promoting wound healing is provided. The method comprises administering to a subject in need an effective amount of Poria cocos extract, dehydropachymic acid (DPA), pachymic acid (PA), dehydrotumulosic acid (DTA), tumulosic acid (TA), polyporenic acid C (PAC), 3-epi-dehydrotumulosic acid (EDTA), dehydrotrametenolic acid (DTTA), trametenolic acid (TTA), dehydroeburicoic acid (DEA), eburicoic acid (EA), poricoic acid A (PAA) and / or poricoic acid B (PAB).

Owner:SINPHAR PHARM CO LTD

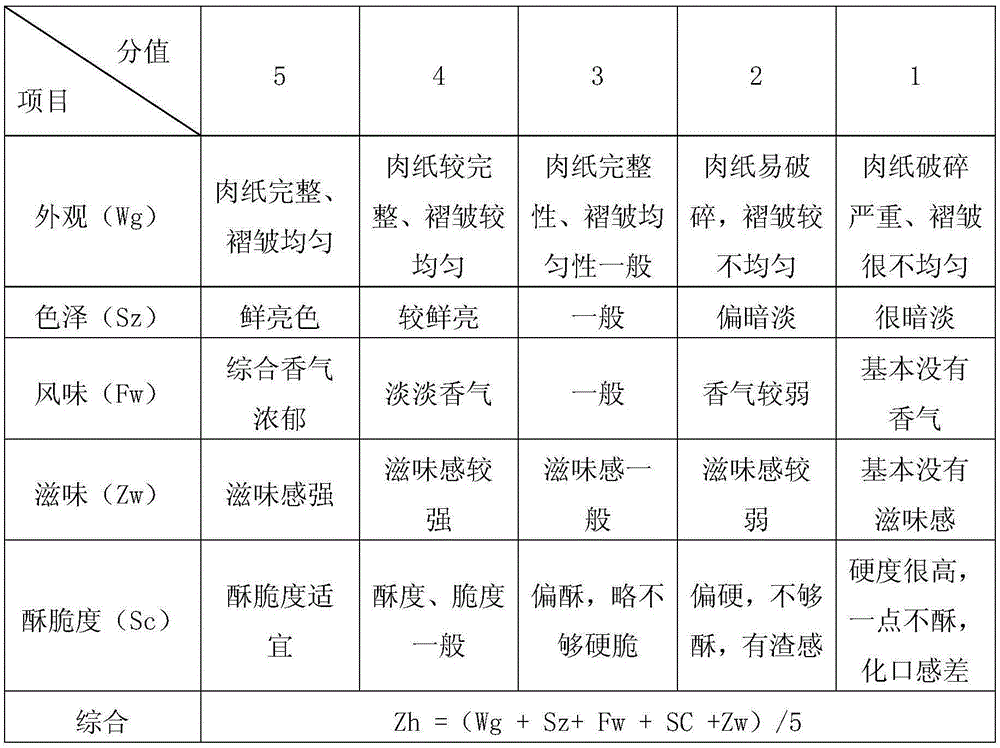

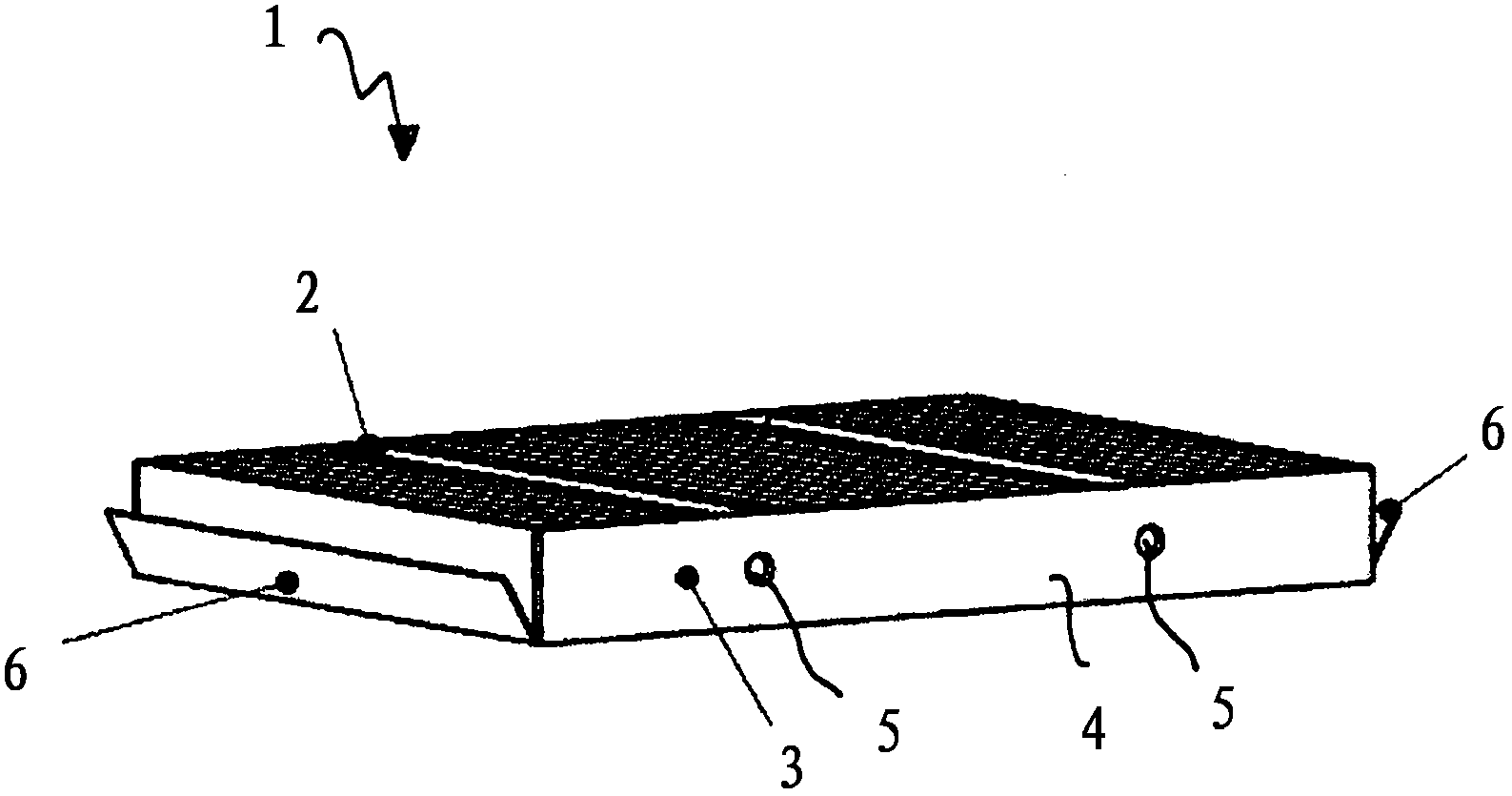

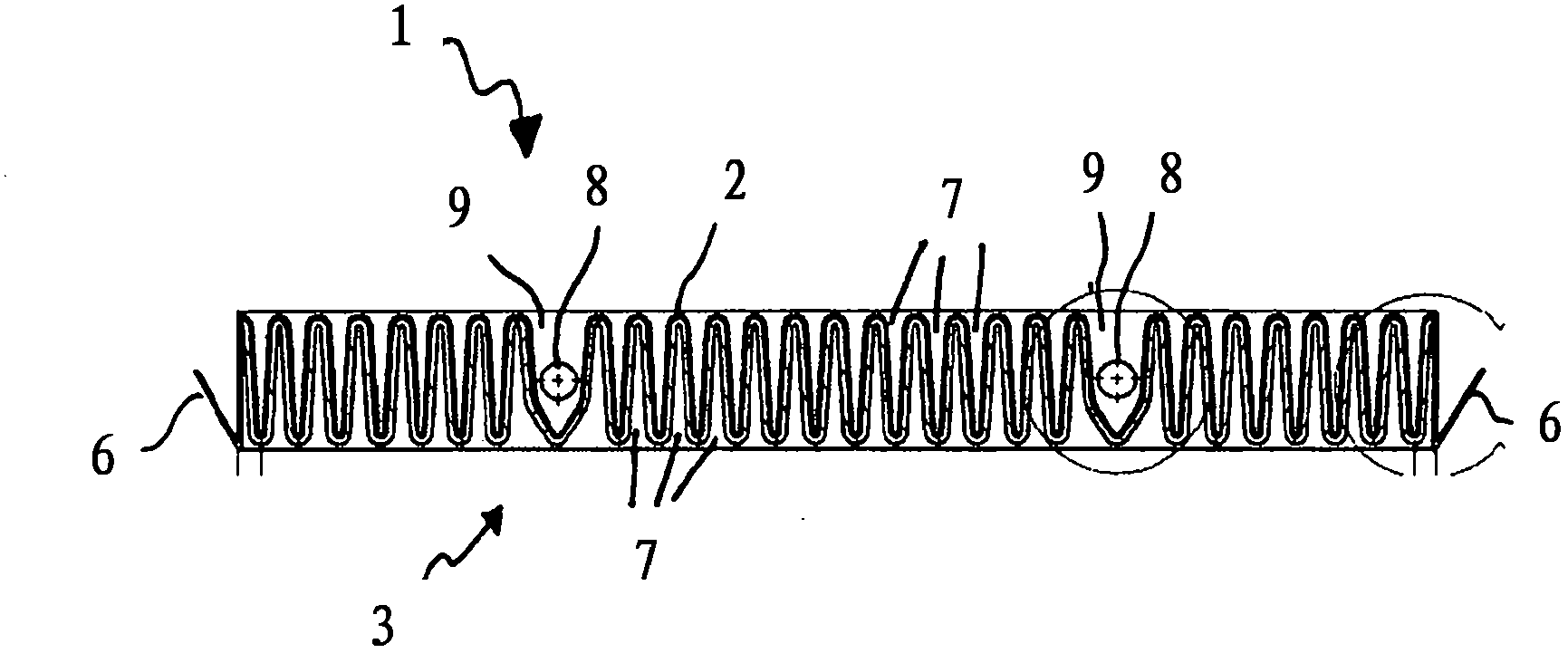

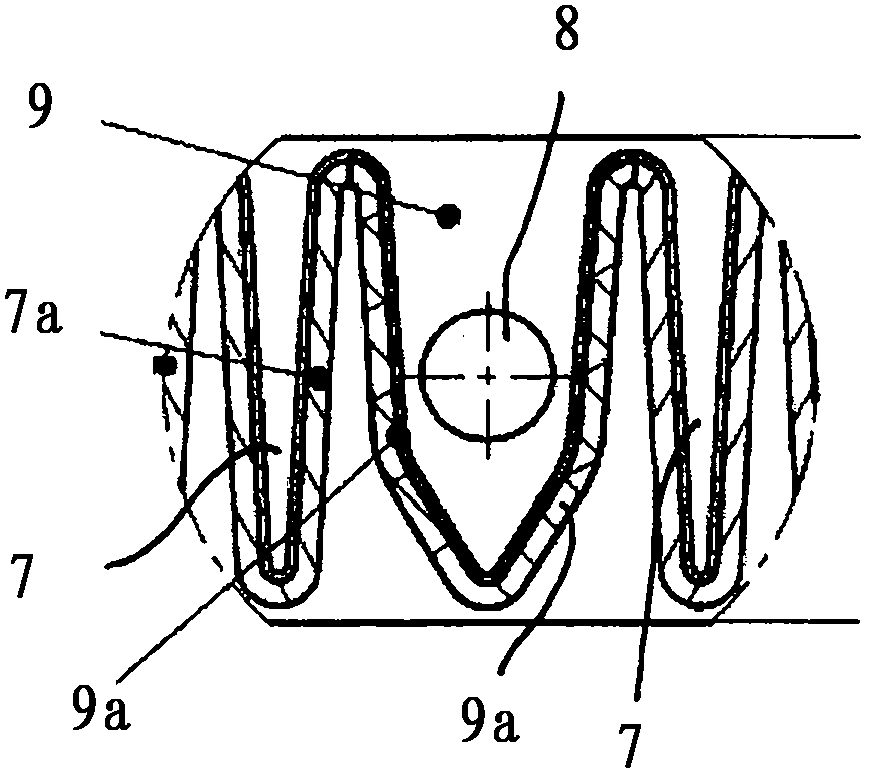

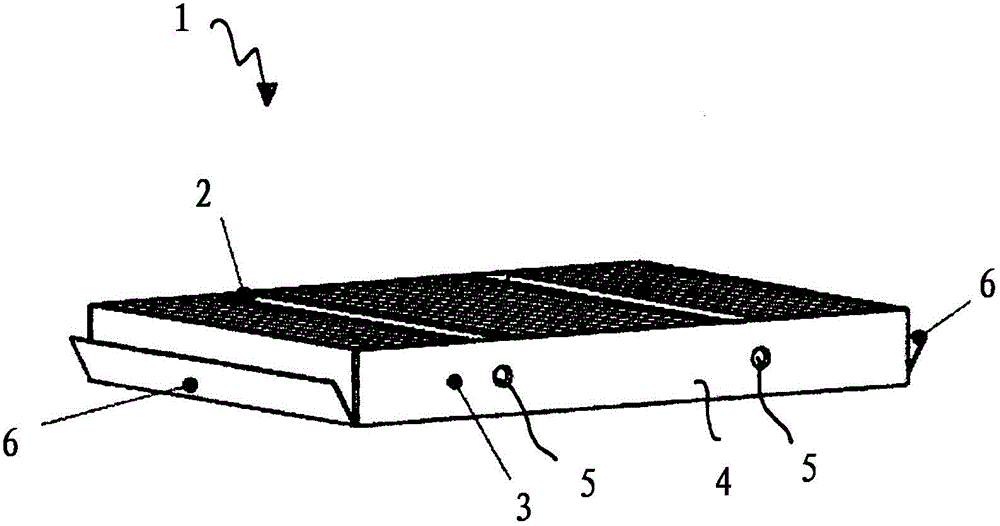

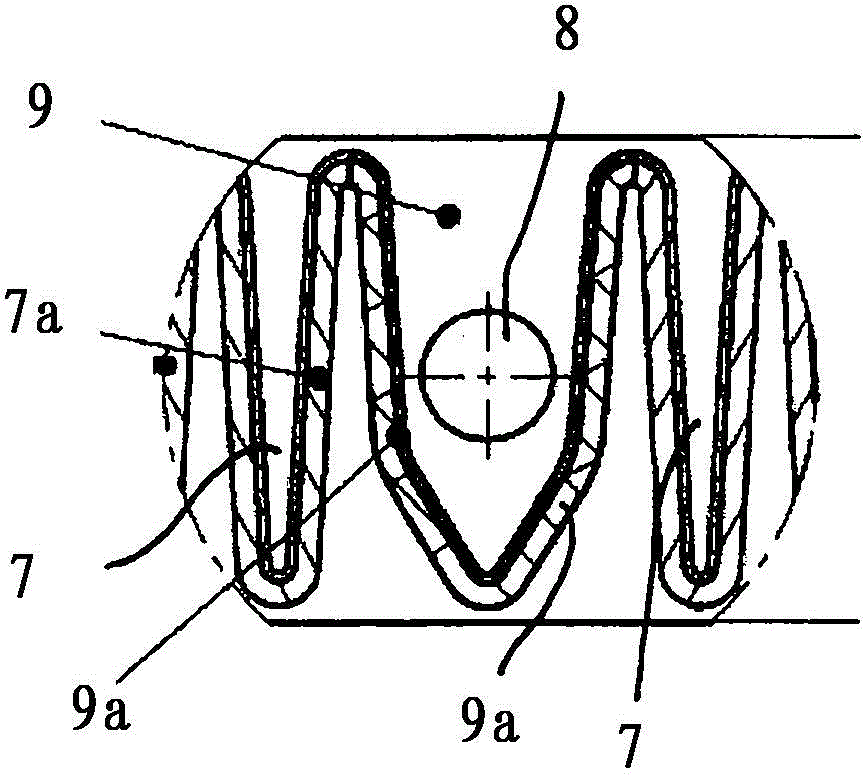

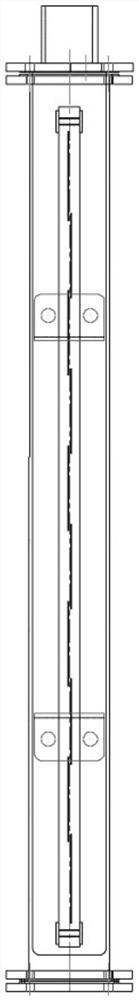

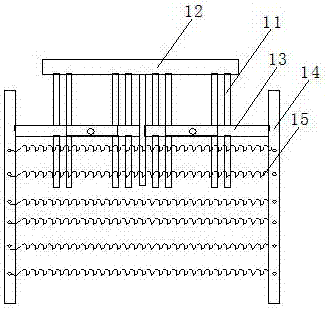

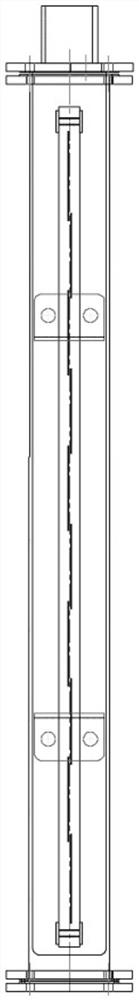

Filter element with guide shaft

ActiveCN102836595ASimple technologyWrinkled evenlyAir-treating devicesMechanical apparatusEngineeringFilter element

A Filter element (1) for insertion into a housing of a ventilation unit or air conditioner, comprising a bellows (2) with folds and a front side (3) which can face a wall of the housing, wherein the folds on the front side define fold cross-sectional surfaces (7,9); the front side is provided with at least one guiding slot (8); and a fold cross-sectional surface (9) in the area of a guiding slot( 8) has a geometry that is different from the fold cross-sectional surface of a multiplicity of folds (7).In view of the task of providing an efficient filter element which, after problem-free manufacture is equipped with guiding slots (8) into which guide pins can be inserted, and characterized in that a multiplicity of regular fold walls (7a) is provided, wherein each two flanking walls (9a) flank the guiding slot (8).

Owner:CARL FREUDENBERG KG

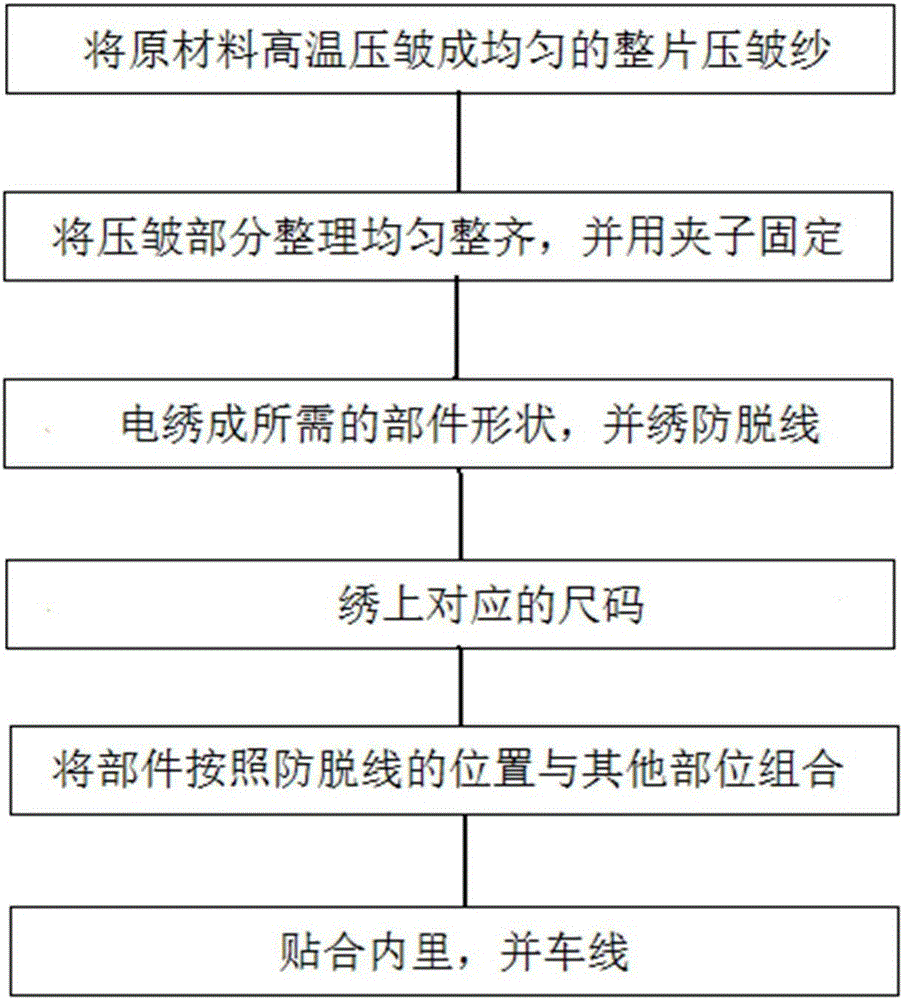

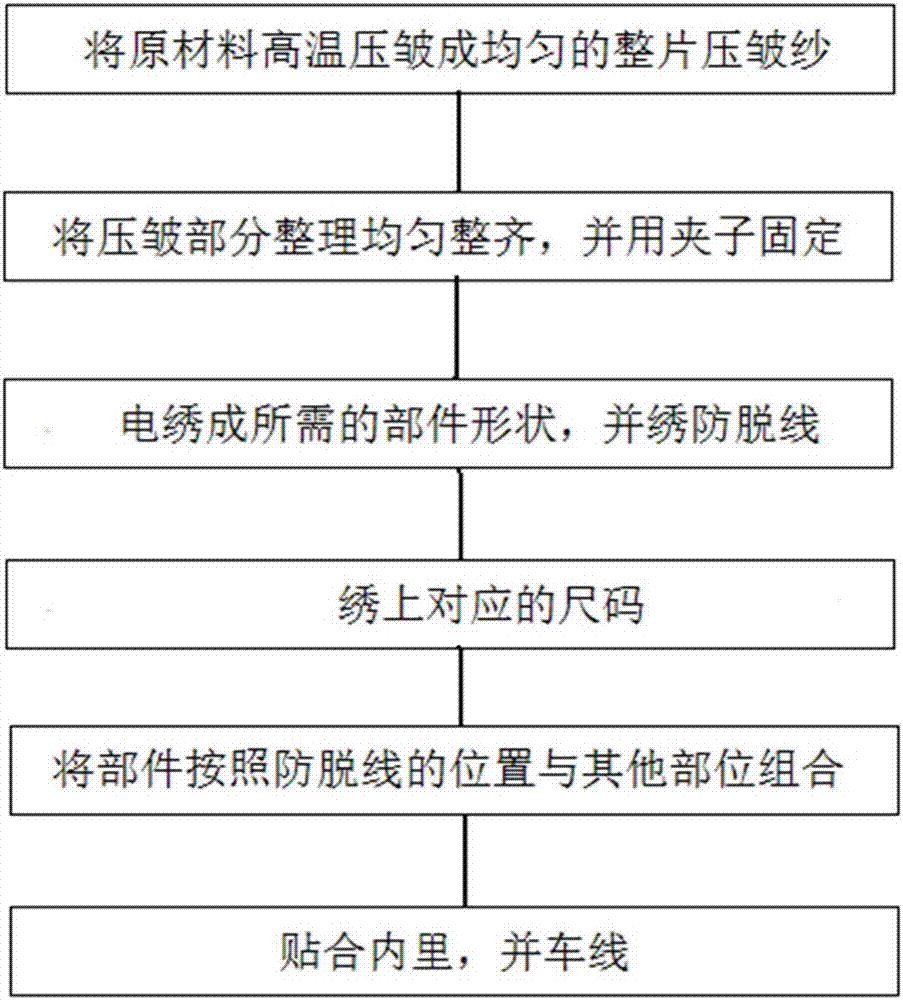

High-temperature-crumpling electrical-embroidering cutting and assembling method used for manufacturing shoes and shoes

The invention provides a high-temperature-crumpling electrical-embroidering cutting and assembling method used for manufacturing shoes and the shoes. The high-temperature-crumpling electrical-embroidering cutting and assembling method comprises the following steps: pressing dense chiffon into a whole piece of uniform crumpled yarn by adopting a high-temperature-crumpling method; arranging the crumpled part of the whole piece of crumpled yarn to be uniform and tidy, and then fixing the whole piece of crumpled yarn by adopting a clip; carrying out electrical-embroidering on the whole piece of crumpled yarn so that the needed part shape is formed, and embroidering detachment-preventing threads on the peripheries of the parts; embroidering the corresponding size on each part; and assembling the part with the other parts according to the positions of the detachment-preventing threads on the peripheries, attaching the formed part to the lining, and carrying out stitching. The shoes are prepared by adopting a process comprising the high-temperature-crumpling electrical-embroidering cutting and assembling method. According to the method, a fabric is crumpled, and then the crumpled fabric is subjected to electrical-embroidering sizing according to the part shape, the sized fabric is cut, the cut parts are assembled, and then the size is electrically-embroidered to the crumpled fabric; the whole process is simple, and the crumpling is uniform and flat; the electrical-embroidering has the size, therefore, a worker can easily distinguish the size during the operation, and thus the cutting and assembling accuracy and the crumpling uniformity can be effectively improved.

Owner:GUANGZHOU RUNKAI IND CO LTD

Pipe material, pipe material manufacturing method and telescopic water pipe

ActiveCN105465501BImprove structural strengthUniform shape deformationPipeline expansion-compensationFlexible pipesWrinkle skinUltimate tensile strength

The invention discloses a pipe, a method for making the pipe and a telescopic water pipe, aiming to provide a pipe that can be stretched, has a uniform structure, and does not produce wrinkle angles when stretching. In the state of natural shrinkage of the pipe body, the pipe wall integrally extends outwards with several flexible convex rings, and in the state of natural shrinkage of the pipe body, the pipe wall integrally extends inward with several flexible concave rings. The pipe body of this structure can be uniform When deforming and shrinking, the outer wall of the pipe is composed of a number of flexible convex ring outer walls, and the inner wall is composed of a number of flexible concave ring inner walls. Or the skin, when stretched, the pipe is approximately tubular, that is, there are tiny wavy structures on the inner and outer walls, which can effectively buffer the force on the inner and outer walls of the pipe, so that the pipe has good structural strength and uniform shape deformation, and has a good application market.

Owner:NINGBO FENGYUAN IMPORT & EXPORT CO LTD

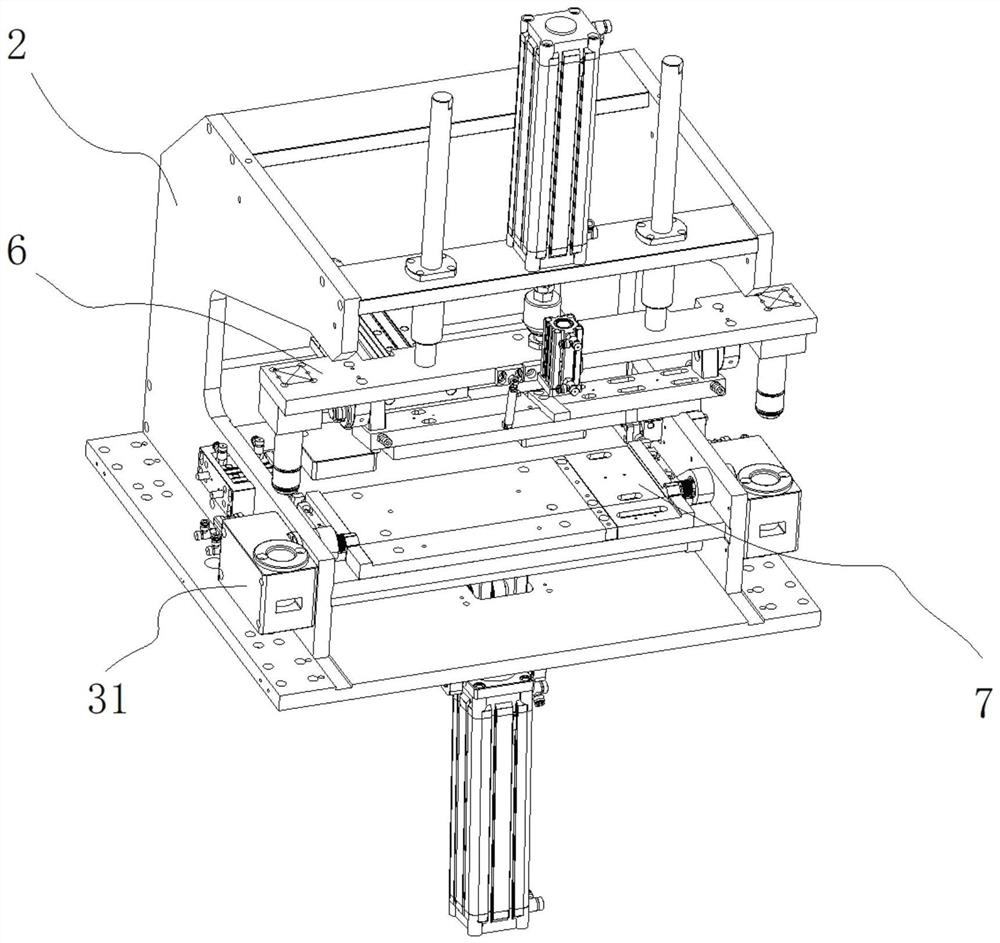

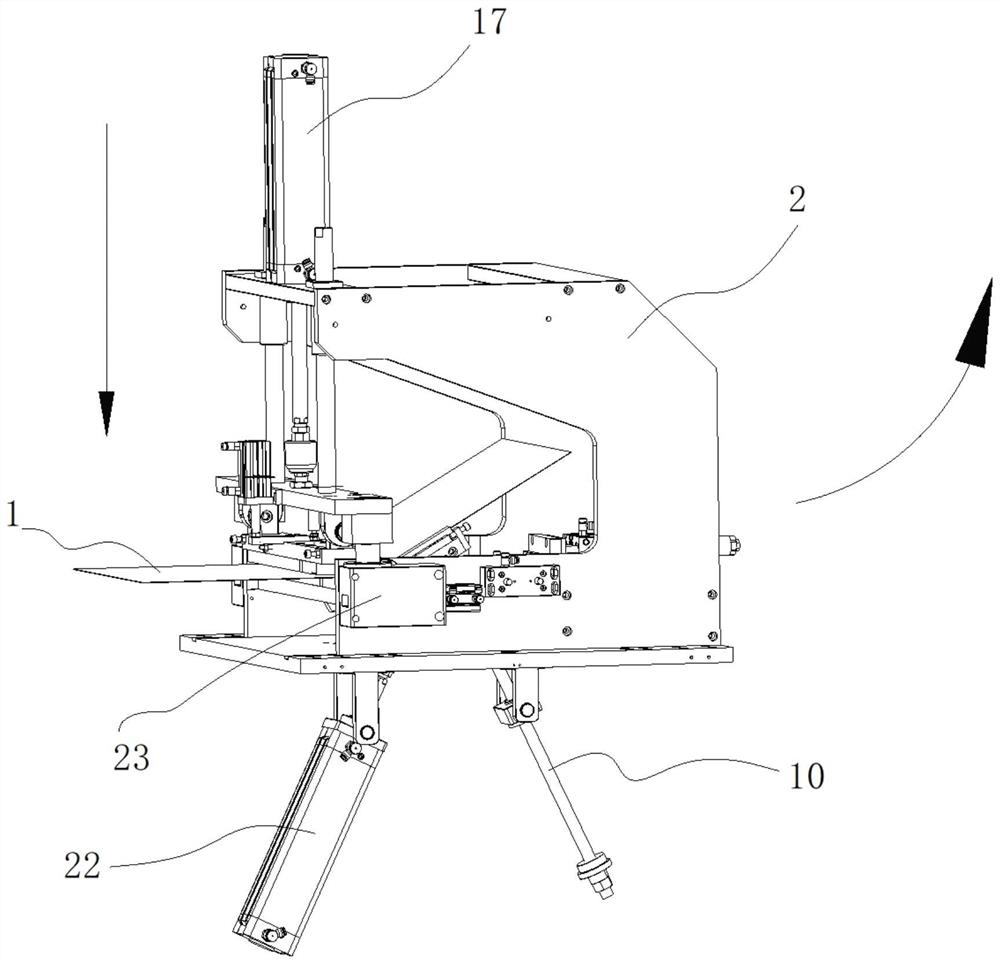

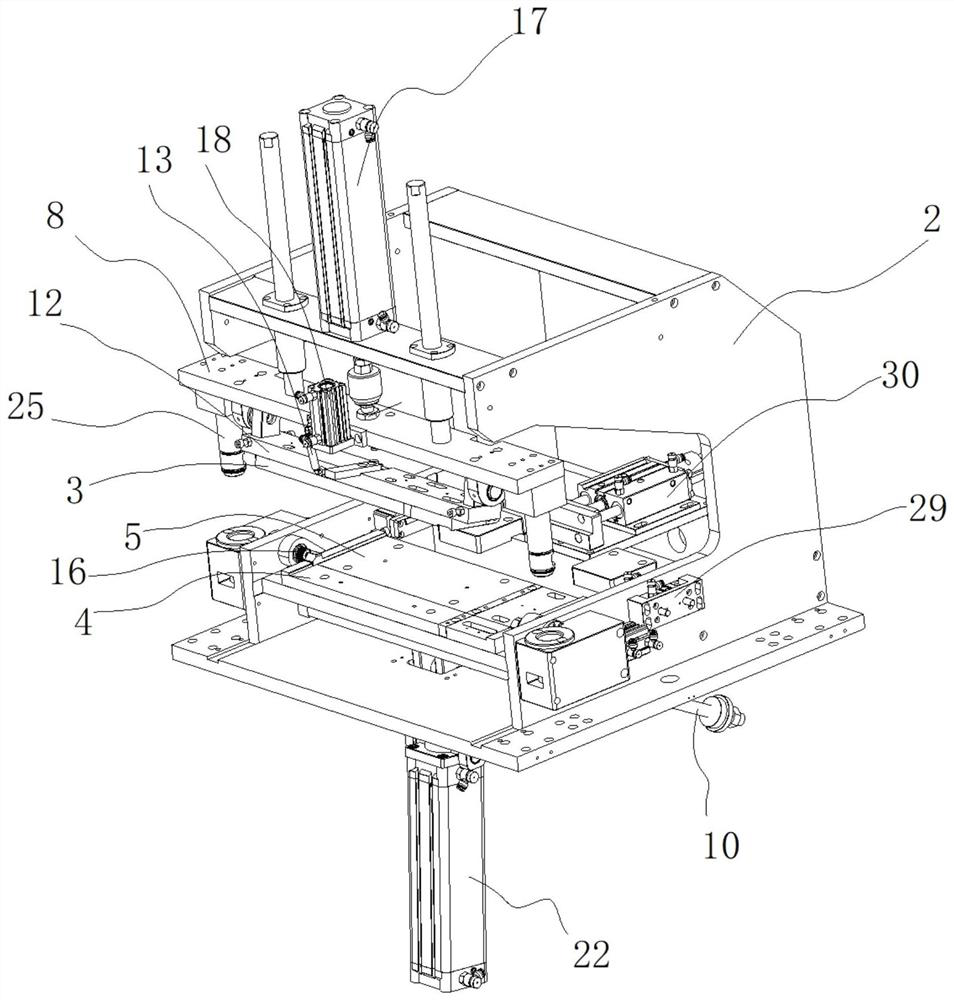

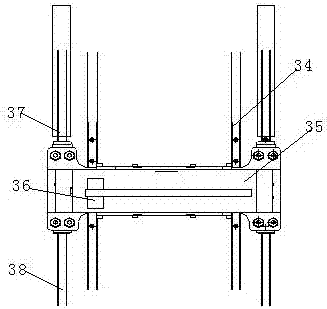

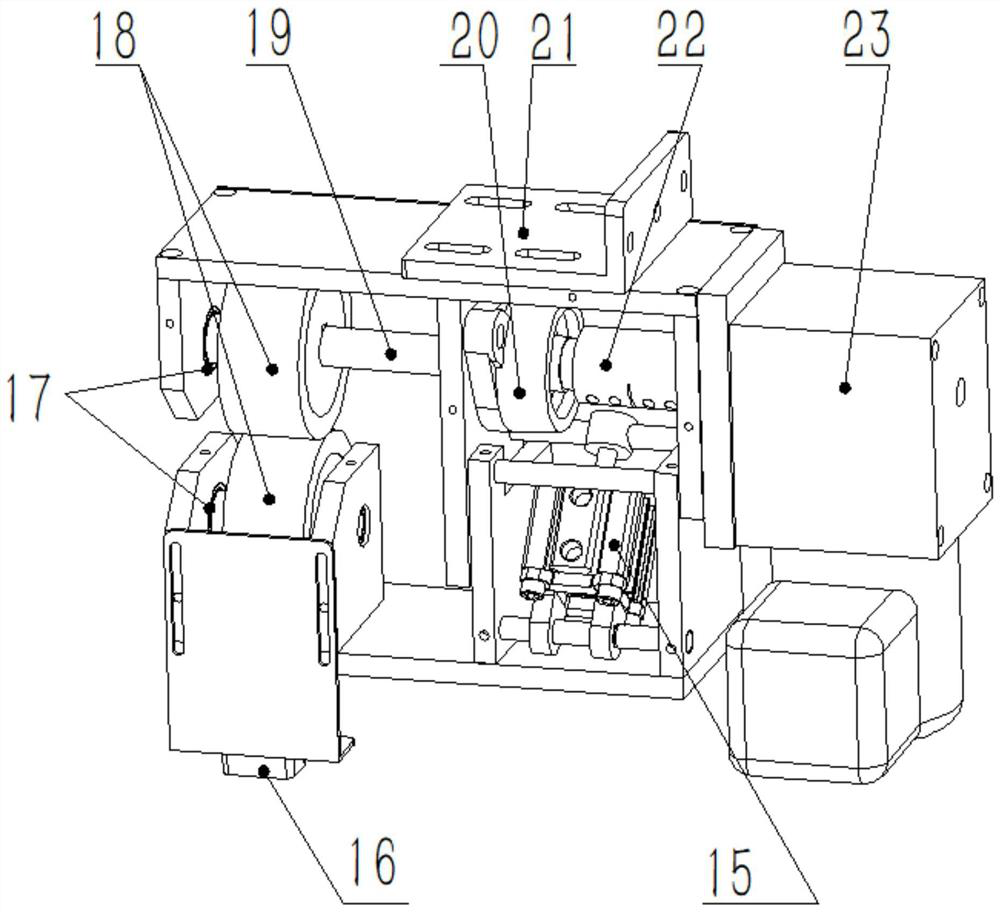

Metal plate bending mechanism and implementation method thereof

The invention relates to a bending mechanism, in particular to a metal plate bending mechanism and an implementation method thereof. The bending mechanism further comprises an operation frame, wherein an upper die material pressing plate capable of moving downwards and turning over is arranged in the upper end of the operation frame, a lower die fixed plate and a lower die movable plate are arranged at the lower end of the operation frame, the lower die movable plate is bent upwards along the lower die fixed plate, and the lower die fixed plate and the lower die movable plate form a bending platform. The bending mechanism is high in structural compactness, the stability of the bending mechanism during product bending is guaranteed, a turnover pressing mechanism can avoid the bent product without damage, and an adjustable and replaceable insert ensures that wrinkles generated at the edge folding position of a product are uniform, uniform and attractive.

Owner:HANGZHOU TAISHANG MACHINERY CO LTD

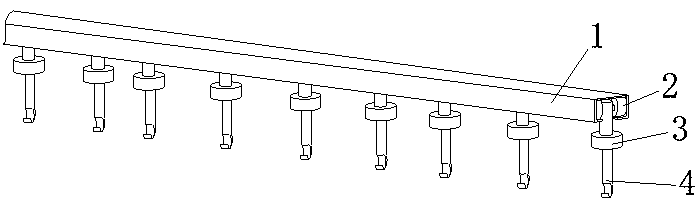

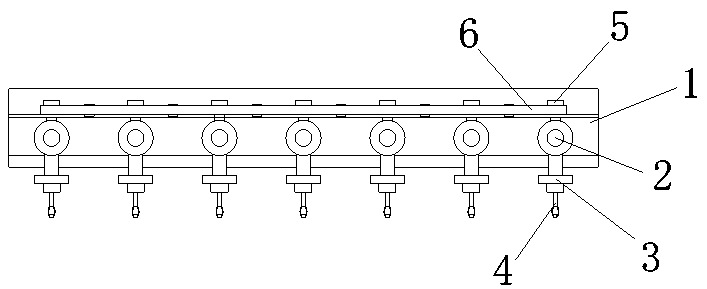

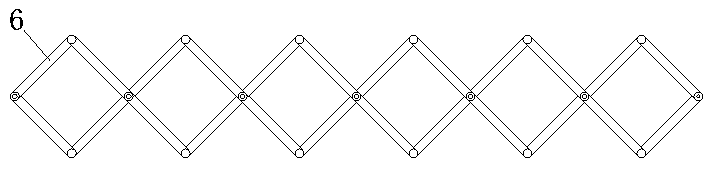

Telescopic device for curtain rail

InactiveCN110326952AWrinkled evenlySynchronous contractionCurtain suspension devicesCurtain rodsEngineering

Owner:SHAOXING COUNTY TIANHONG CURTAIN ZONE CO LTD

A sheet metal bending mechanism and its realization method

ActiveCN112893541BGuaranteed stabilityImprove compactnessStructural engineeringMechanical engineering

Owner:HANGZHOU TAISHANG MACHINERY CO LTD

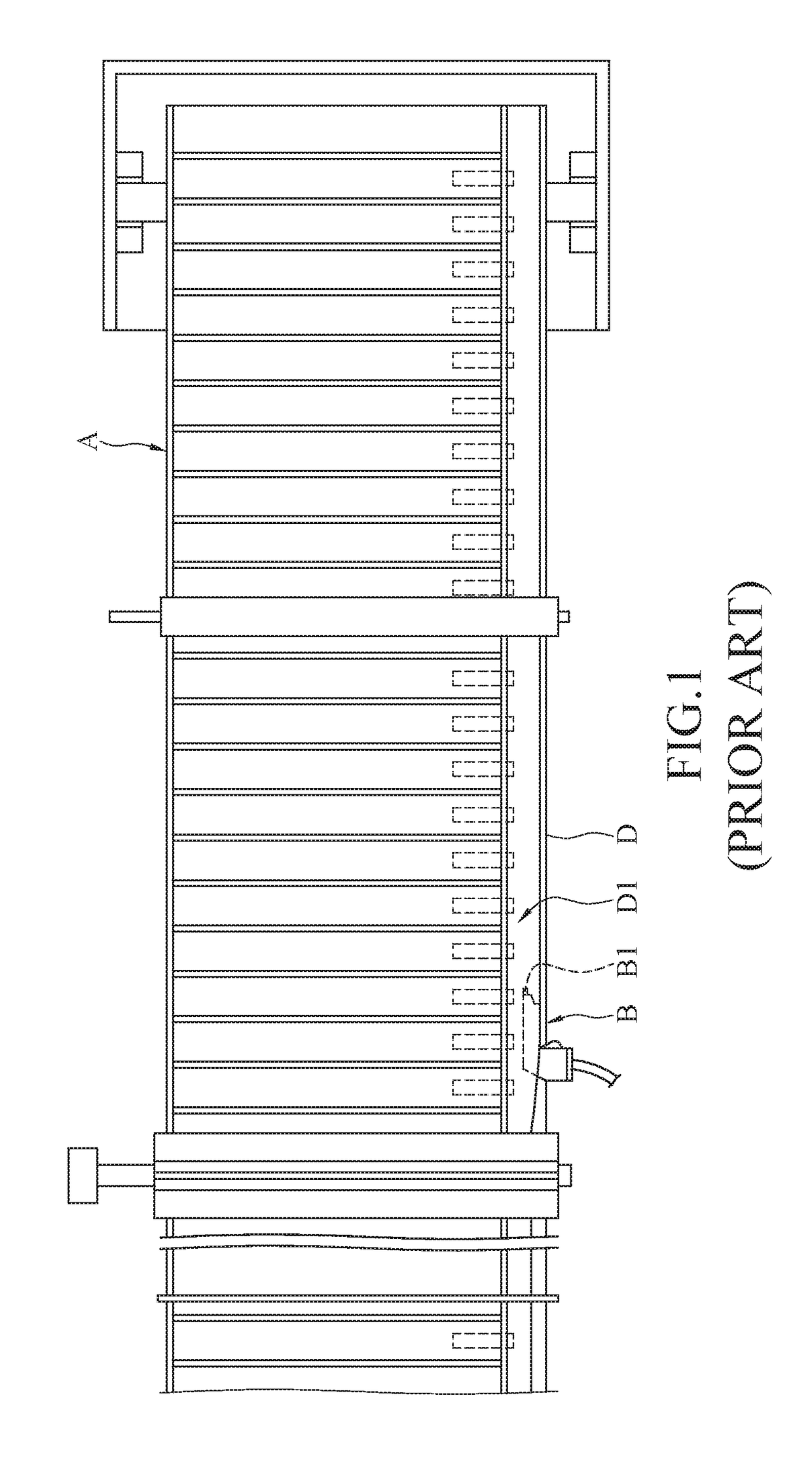

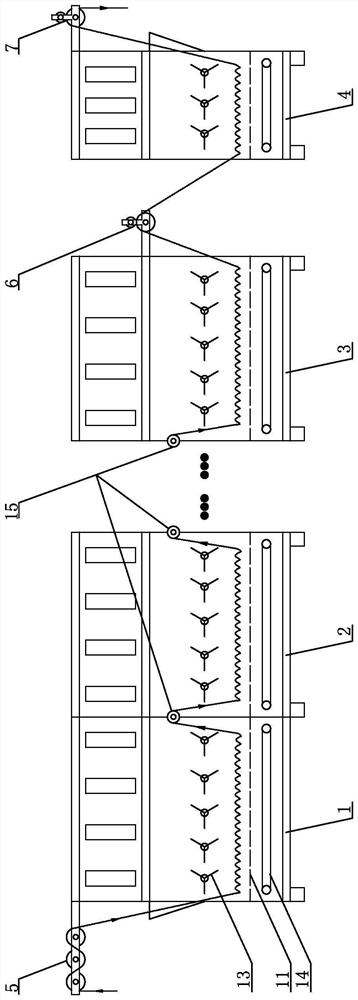

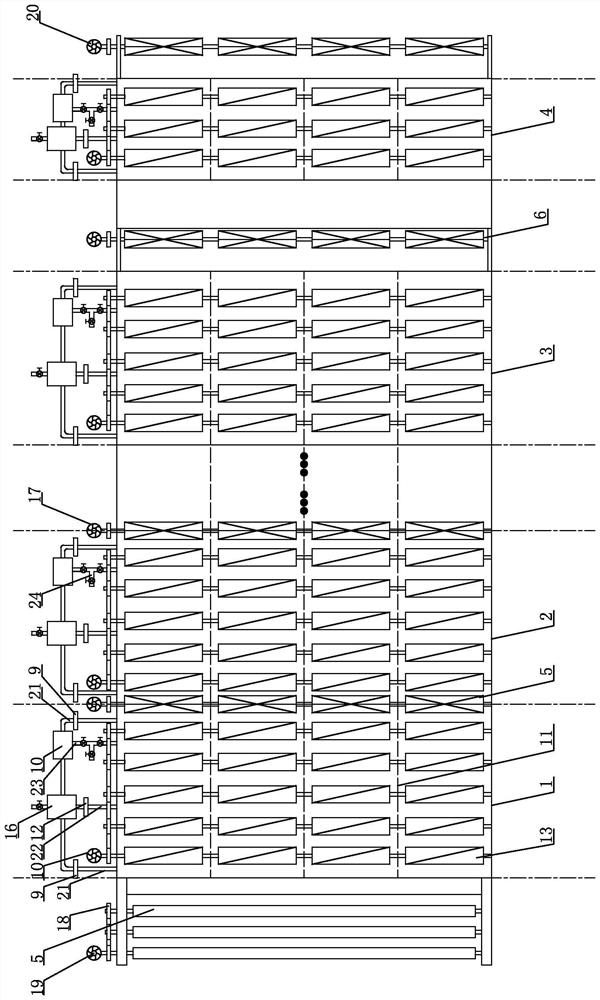

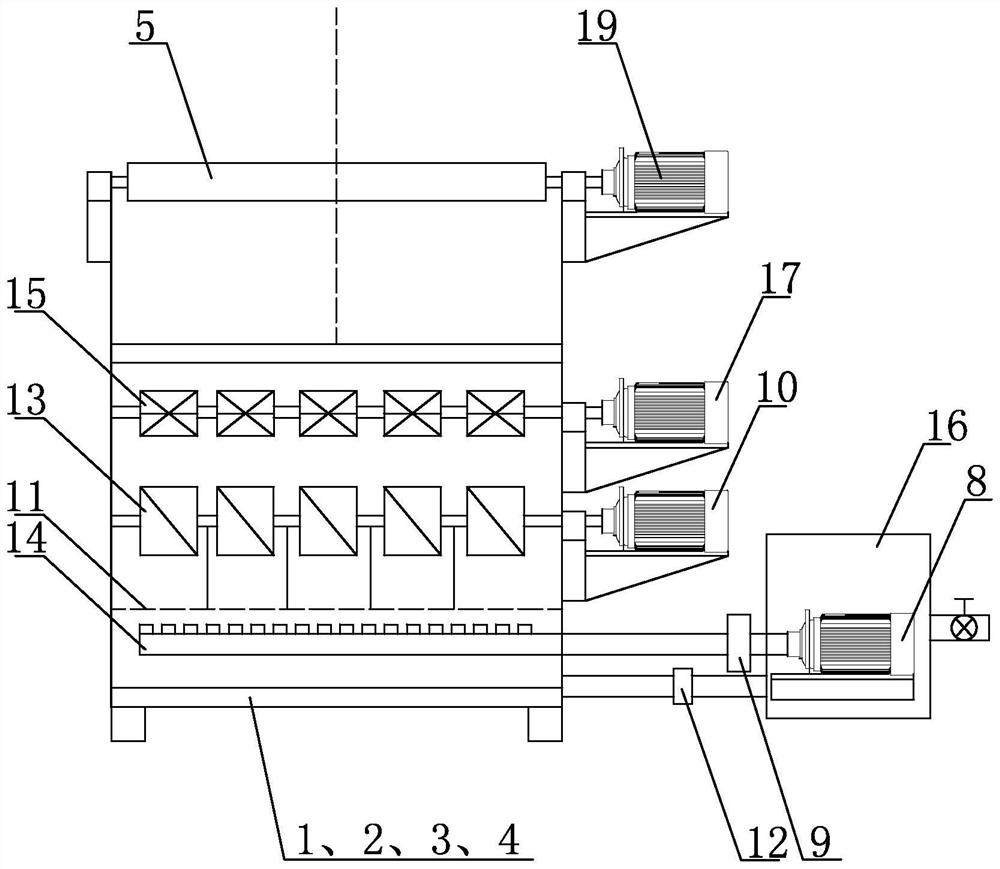

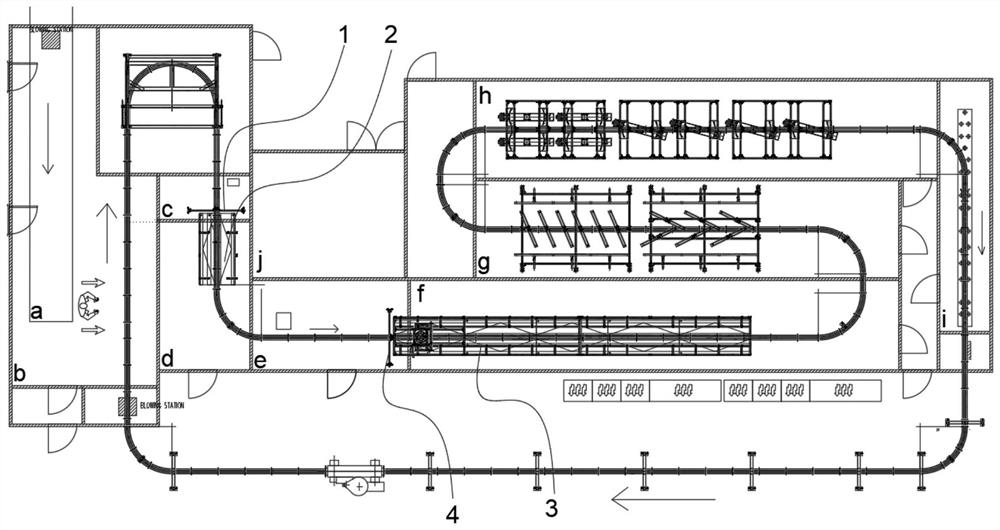

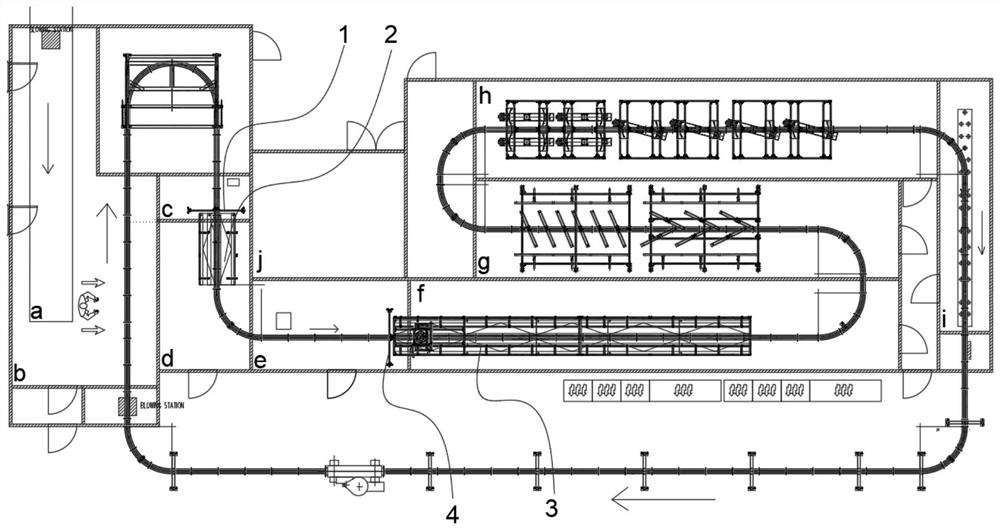

Efficient energy-saving continuous bubbling and wrinkling oxygen bleaching dyeing machine and material conveying method thereof

InactiveCN114108213AReasonable structureEasy to operateSucessive textile treatmentsTextile treatment machine arrangementsProcess engineeringIndustrial engineering

The invention belongs to an efficient and energy-saving continuous bubbling, wrinkling and oxygen bleaching dyeing machine and a conveying method thereof.The efficient and energy-saving continuous bubbling, wrinkling and oxygen bleaching dyeing machine comprises a machine head barrel module, a plurality of middle barrel modules, a machine tail barrel module, a neutralizing barrel module, a roller set driving mechanism and an auxiliary conveying system; a cloth discharging roller set is arranged at the discharging end of the neutralizing barrel module, and a conveying roller set is arranged between every two barrel modules; a plurality of conveying channels are divided in each barrel module, the upper portions and the lower portions of the conveying channels and the two adjacent conveying channels are separated through net plates, cloth turning rollers are arranged on the upper portions of the conveying channels, and cloth turning pipes communicated with an auxiliary conveying system are arranged on the lower portions of the conveying channels. Compared with the prior art, the device has the advantages that the structure is reasonable, the operation is simple, the cost is saved, the boiling and dyeing processes of the textile fabric can be automatically and continuously finished, the textile fabric has excellent wrinkling and foaming effects, and the textile fabric can be effectively prevented from generating large wrinkles, dead wrinkles, sand edges and other inferior-quality products.

Owner:王绍福

Filter element with guide shaft

ActiveCN102836595BSimple technologyWrinkled evenlyAir-treating devicesMechanical apparatusEngineeringFilter element

A Filter element for insertion into a housing of a ventilation unit or air conditioner, comprising a bellows with folds and a front side, which can face a wall of the housing, wherein the folds on the front side define fold cross-sectional surfaces, wherein to the front side at least one guiding slot is assigned and wherein a fold cross-sectional surface has a geometry in the area of a guiding slot that is different from the fold cross-sectional surface of a multiplicity of folds, is, in view of the task of providing an efficient filter element which, after problem-free manufacture is equipped with guiding slots into which guide pins can be inserted, characterized in that a multiplicity of regular fold walls is provided, wherein each two flanking walls flank the guiding slot.

Owner:CARL FREUDENBERG KG

Production system capable of increasing coating layer thickness by pre-wetting surface and coating method

ActiveCN111842042AWrinkled evenlyEasy to wet and spreadLiquid surface applicatorsCoatingsMechanical engineeringSurface coating

The invention relates to the field of surface coating layer and coating, and discloses a production system capable of increasing coating layer thickness by pre-wetting a surface. The production systemcapable of increasing coating layer thickness by pre-wetting the surface comprises a feeding room used for placing to-be-coated products on a conveying belt, a first coating area, a first drip dryingarea, a second coating area, a second drip drying area, and a solidifying area. The areas above are connected by the conveying belt in order. The first coating area and the second coating area are respectively provided with a first coating machine and a second coating machine. The first drip drying area and the second drip drying area are used for the drip drying and levelling of the to-be-coatedproducts. The solidifying area enables coating layers on the to-be-coated products to dry completely. The feeding room is internally provided with the conveying belt for conveying the to-be-coating products. The production system capable of increasing coating layer thickness by pre-wetting the surface and a coating method can form the coating layers of uniform high thickness and smooth surface without folds on the surface of complex three-dimensional products.

Owner:SUN YAT SEN UNIV +1

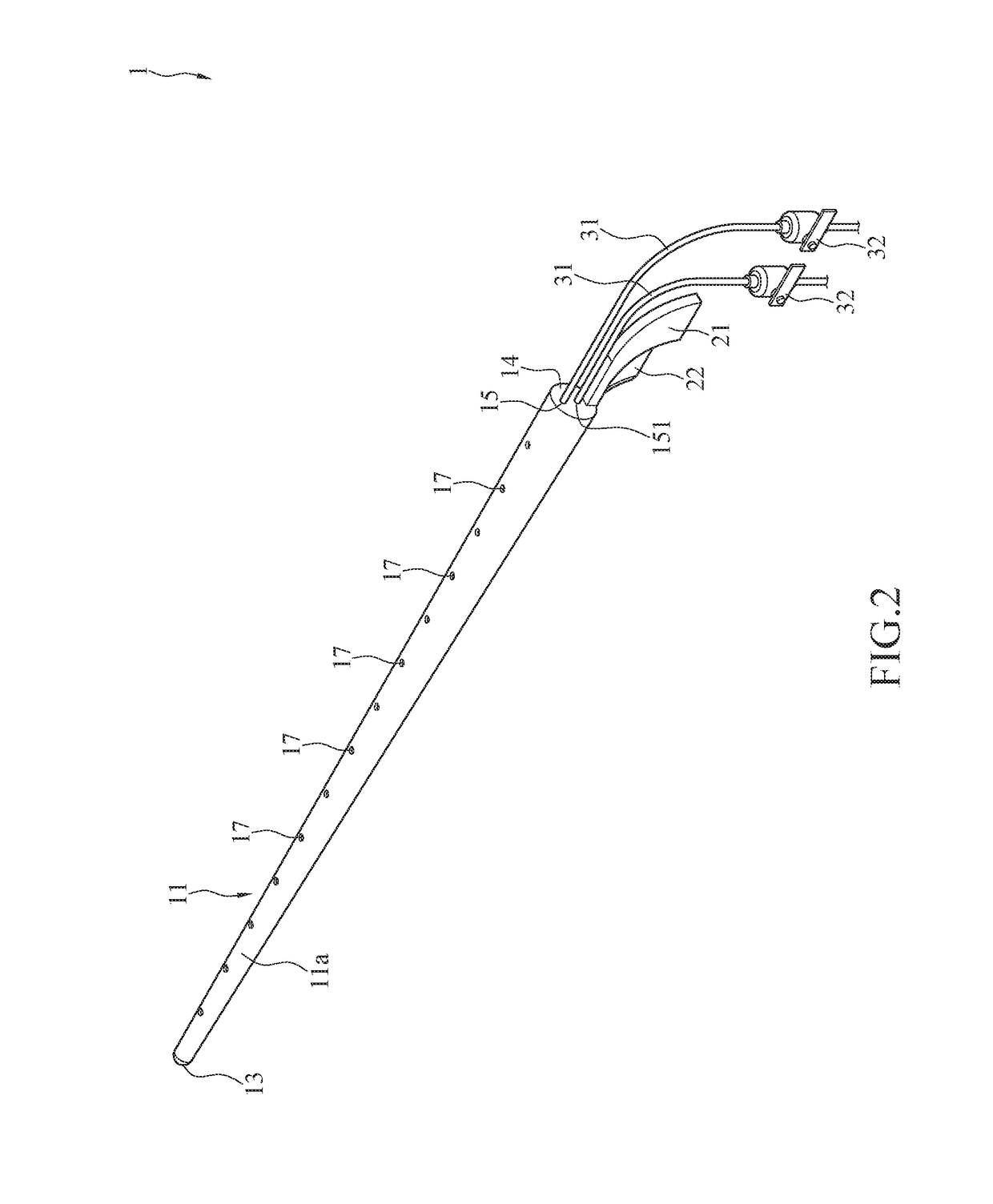

Bear self-tissue drainage catheter and production method for fetching bile from artificial vertical type ruga

InactiveCN101301226AEasy and fast intubationEliminate bile leakageCatheterSurgical veterinaryDrainage cathetersCatheter

The invention discloses a method for making a bear autogenous tissue drainage catheter and artificial longitudinal type ruga bile taking. The method comprising the following: a step of abdomen opening, which is to make a longitudinal type ruga closed pouch at the bottom of a gallbladder; a drainage catheter is made by means of a jejunum or a gallbladder tissue; the catheter is matched with or connected with the gallbladder and then is straightened up; and an extracutaneous drainage opening is made. The longitudinal type ruga is made through adopting a suture method or a knotting method with the ruga number reaching to three to six, and rugae are even and tightly closed after ruga making, thereby solving the problem of bile leakage after an operation; moreover, the method is convenient for inserting a pipe to take bile, and the bile taking time is only 1 to 1.5 minutes; bile taking can be carried out twice every day without the occurrence of stricture or atresia of the drainage opening and the drainage catheter, thereby ensuring stronger anti-infection immunizing power and repairing capacity.

Owner:吉林松宝制药有限公司

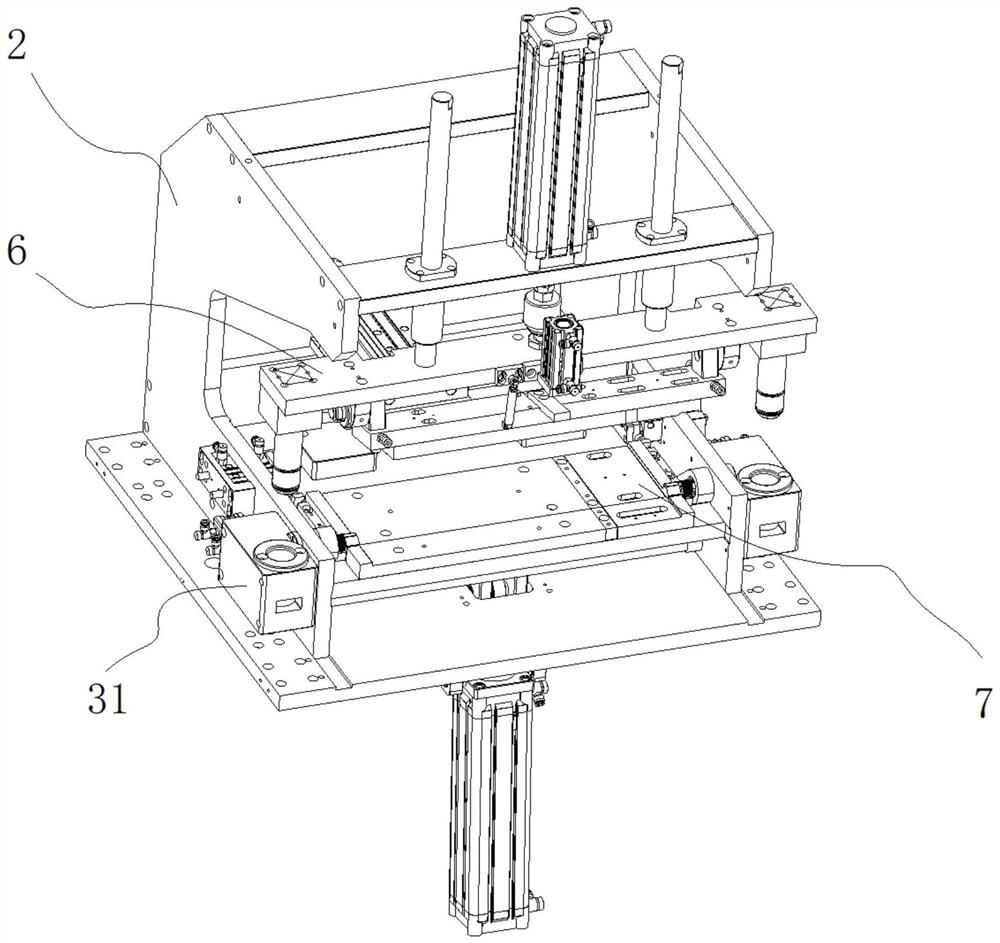

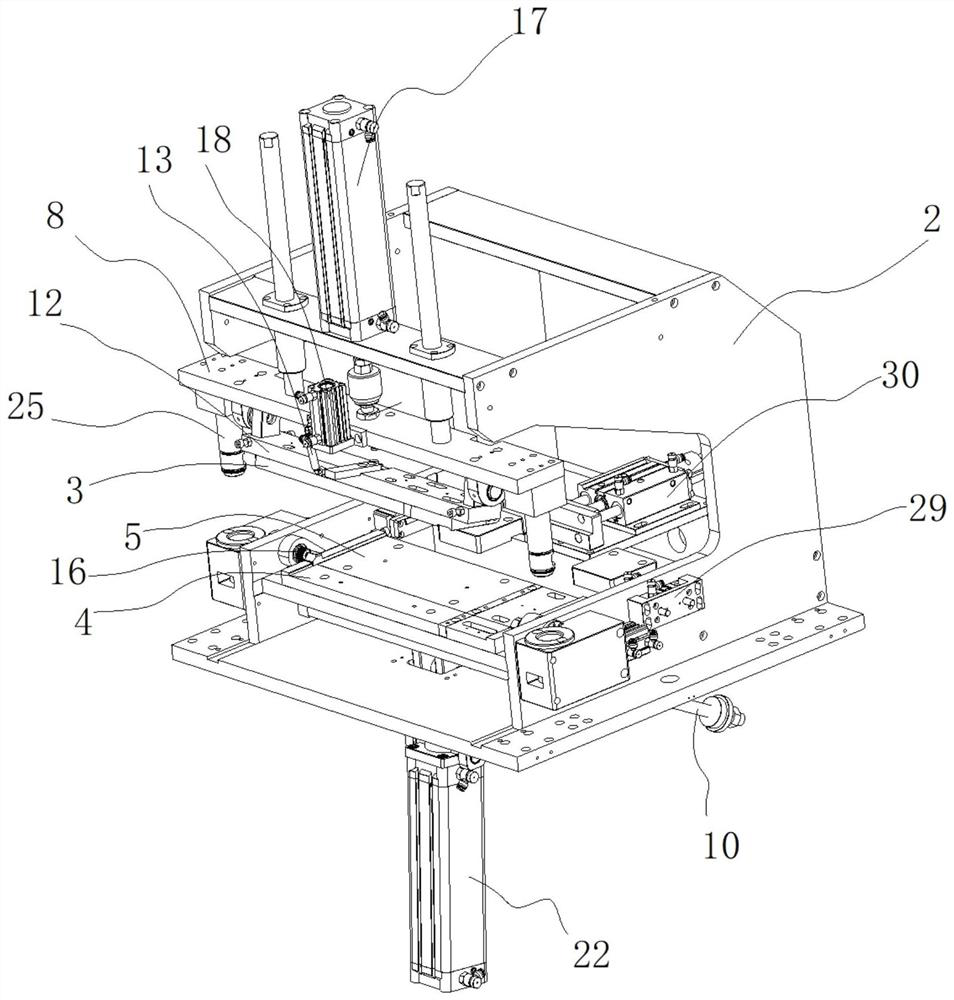

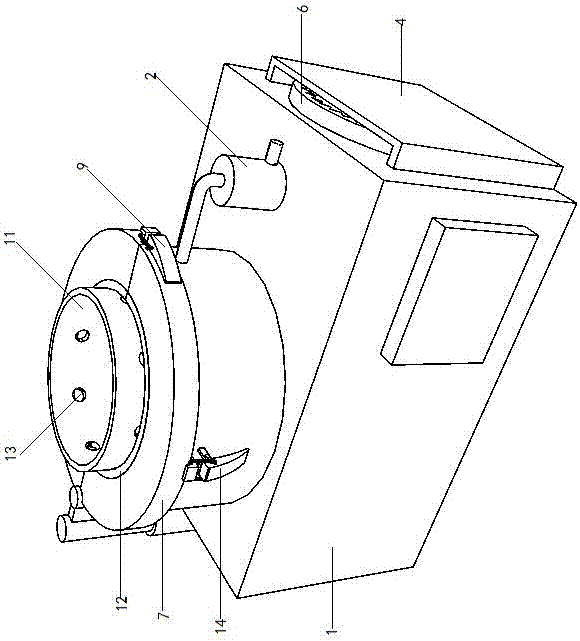

Combined forming equipment suitable for filtered water core material

The invention discloses combined forming equipment suitable for a filtered water core material. The combined forming equipment is characterized by comprising an emptying structure and core material bending material separation equipment, wherein the emptying structure is a trapezoidal frame body; a top roller placing block and two lateral roller placing blocks are arranged on the frame body; the core material bending material separation equipment comprises a workbench and a material processing cabin arranged at the upper part of the workbench, a table feeder is arranged at the right end of the material processing cabin, a material trimming structure and a material separation structure are arranged on the table feeder, and a plurality of processing units are arranged in the material processing cabin. The combined forming equipment has the beneficial effects that a material leveling unit, a material bending unit and a material splitting unit are adopted in the filtering processing cabin, and the emptying structure, the material trimming structure and the material separation structure are prepared, so that tight combination, uniform wrinkles and equivalent material separation of the filtered water core material are guaranteed. The quality of the product is further improved, the service life of the product is prolonged, and meanwhile the structure is reasonable in configuration and convenient to use.

Owner:芜湖市三山区绿色食品产业协会

Pigment-free, transparent and crispy meat paper and its processing method

ActiveCN105360972BComplete appearanceWrinkled evenlyFood scienceRoom temperatureIsolated Soy Protein

The present invention discloses a pigment free, transparent, thin and crisp meat paper and a processing method thereof. The processing method comprises the following processing steps: 1) weighing raw materials of raw material meat, iced water, nuts, auxiliary materials, isolated soy proteins, glucose, crisp agent, and D-sodium erythorbate in proportion; 2) mixing the above raw materials evenly and pickling the mixed raw materials to obtain a filling material; 3) pouring the filling into a mold to be compacted tightly into a block meat base material and quickly freezing the meat base material; 4) placing the frozen meat base material under a temperature of 10-20 DEG C for storage and when the center temperature is raised to -3 to -5 DEG C, slicing the meat base material into thin meat slice using a slice cutter; 5) firstly conducting a low-temperature drying for the thin meat slice, then conducting a high temperature drying and curing of the low-temperature dried thin meat slice, air-blowing the dried thin meat slice after curing, and cooling the thin meat slice into a room temperature to obtain the transparent, thin and crisp meat paper; 6) placing the transparent and thin meat paper in a packaging workshop with a relative humidity less than 40% and packaging and storing the thin meat paper. The obtained meat paper has a complete appearance, and is even in folds, not easily broken, strong in sense, and transparent, crisp and so on.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

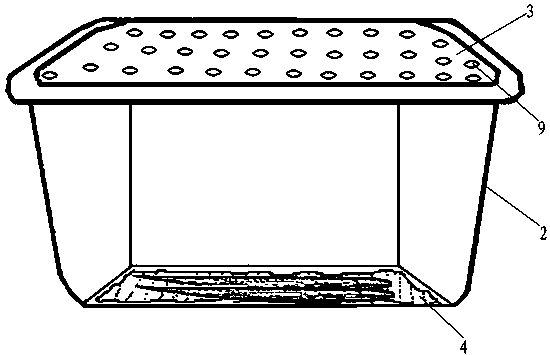

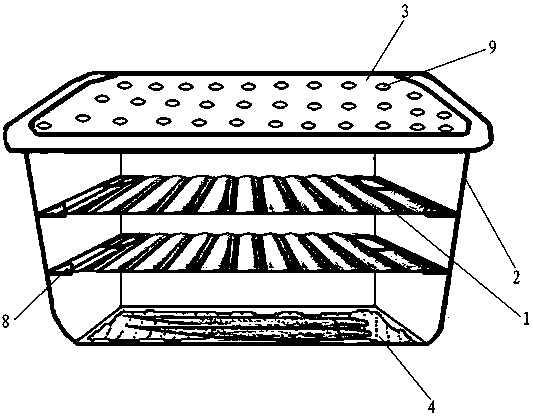

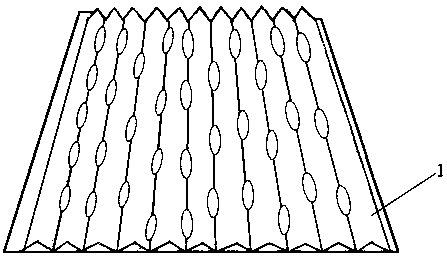

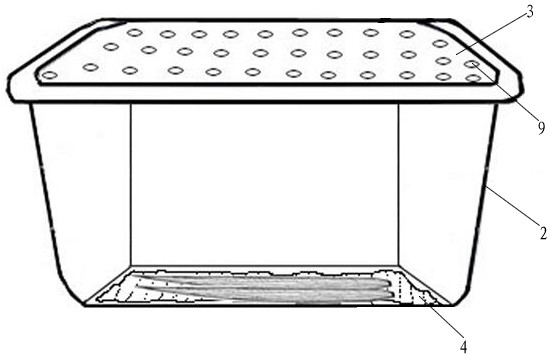

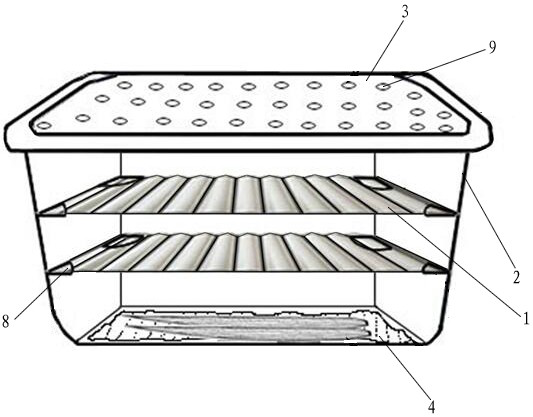

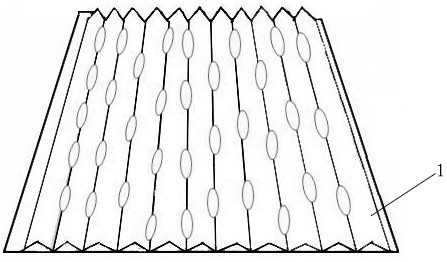

Mycodiplosis sp. collecting and releasing device and collecting and releasing technique

ActiveCN111418555AEfficient collectionThe method of collecting the chrysalis gall midge pupae is efficientInsect catchers and killersPupaMycodiplosis

The invention discloses a mycodiplosis sp. collecting and releasing device. The mycodiplosis sp. collecting and releasing device comprises a pupa collecting device and a releasing device, wherein thepupa collecting device and the releasing device both comprise transparent corrugated plastic PP plates; the pupa collecting device also comprises a transparent plastic box body, a box cover, moisturepreserving gauze and transparent corrugated plastic PP plates, and the transparent corrugated plastic PP plates and the inner wall of the box body are in dismountable connection through connecting assemblies; and the releasing device also comprises an accommodating box, a cover body, separating meshes and moisture preserving gauze. The collecting and releasing device and method disclosed by the invention are efficient, simple and convenient, simple to operate, labor-saving and time-saving.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

A production system and coating method for increasing coating thickness by surface prewetting

ActiveCN111842042BWrinkled evenlyEasy to wet and spreadLiquid surface applicatorsCoatingsConveyor beltSurface coating

The invention relates to the field of surface coating coating, and discloses a production system for increasing coating thickness through surface prewetting, including a feeding room for placing coated products on a conveyor belt, a first coating area, a first drop Drying area, second coating area, second dripping dry area, curing area; the above-mentioned areas are sequentially connected by a conveyor belt; the first coating area and the second coating area are respectively equipped with a first coating machine, a second Coating machine; the first dripping area and the second dripping area are used for the dripping and leveling of the coated product; the curing area can completely dry the coating on the coated product; in the feeding room Equipped with coated product conveyor belt. The purpose of the present invention is to provide a production system and coating method for increasing coating thickness through surface pre-wetting, which can form a coating with uniform high thickness and smooth surface without wrinkles on the surface of complex three-dimensional products.

Owner:SUN YAT SEN UNIV +1

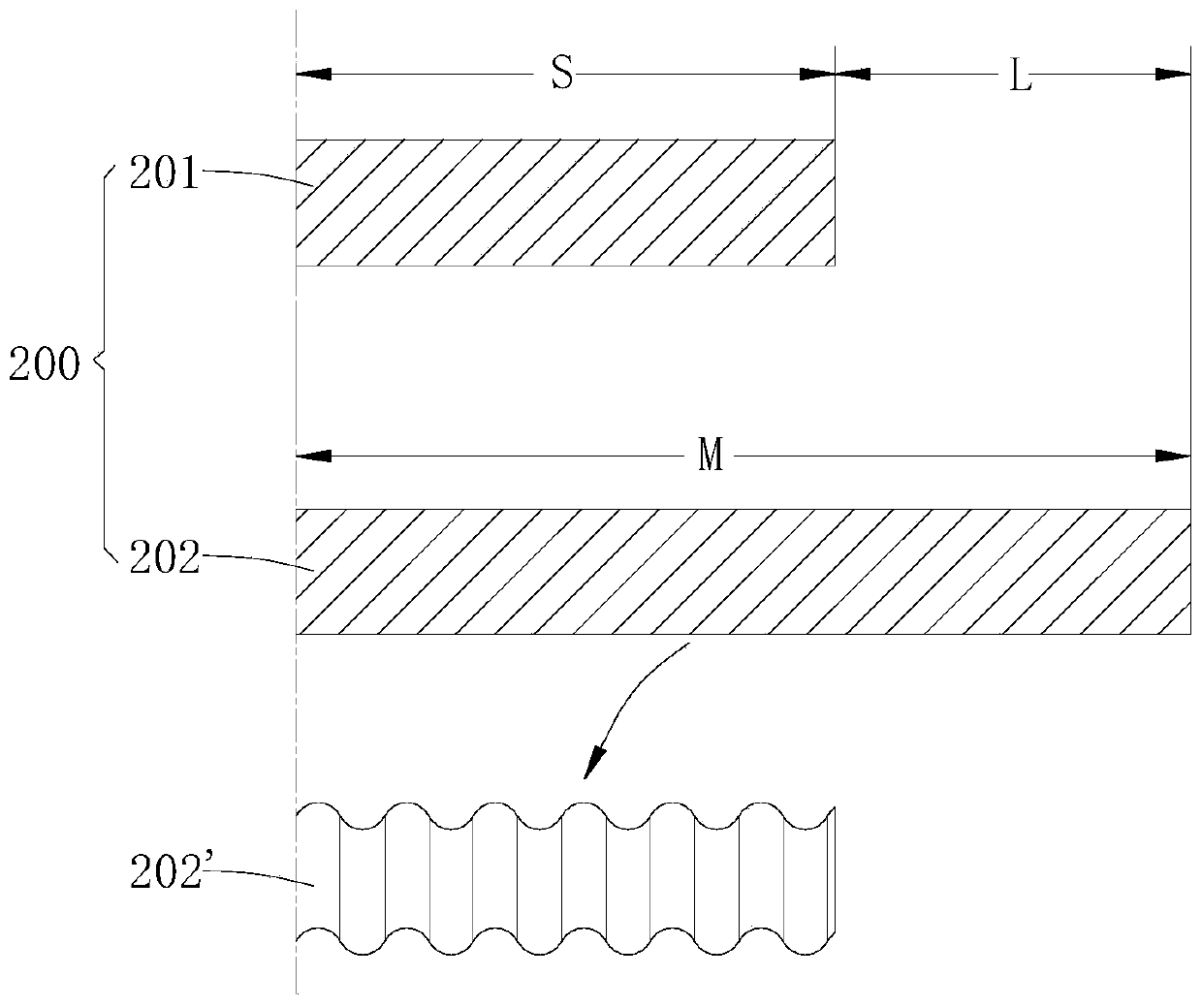

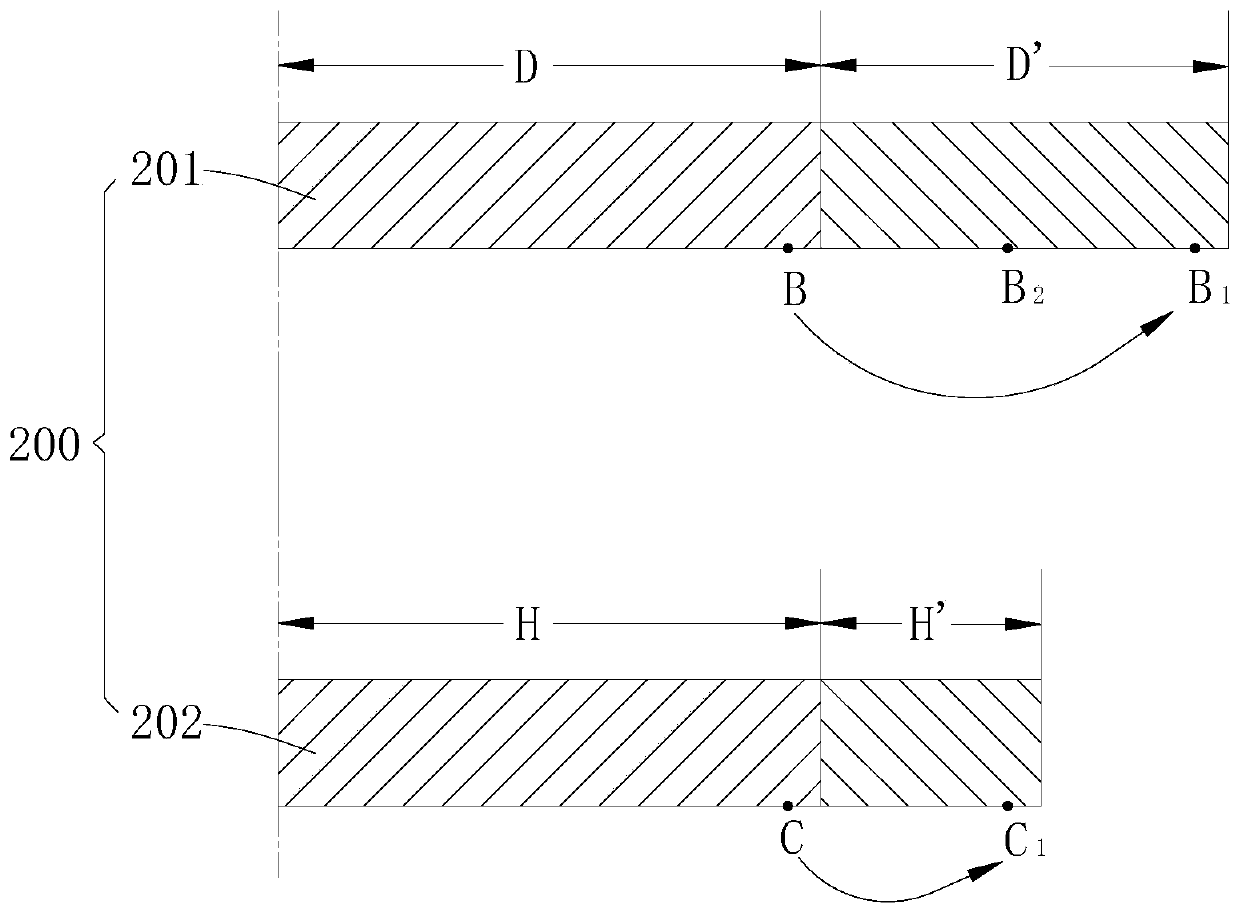

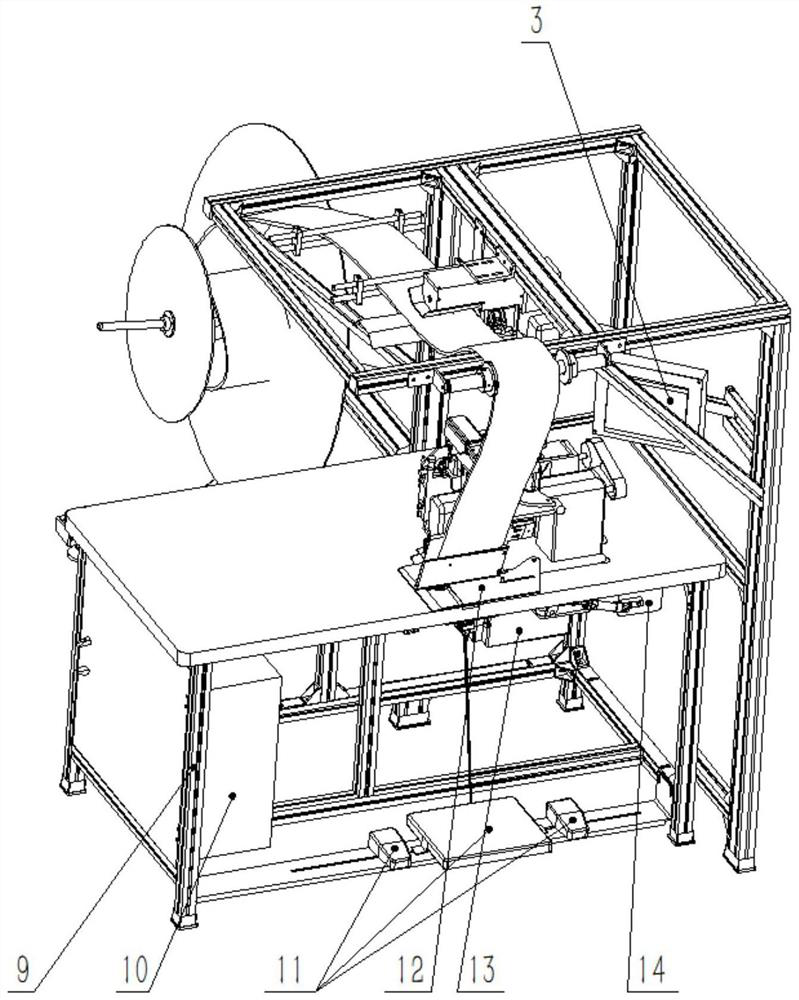

Sewing control method and system of sewing machine

InactiveCN110396773AWrinkled evenlyImprove sewing qualityProgramme-controlled sewing machinesWork-feeding meansControl systemEngineering

The invention discloses a sewing control method and system of a sewing machine. The sewing control method of the sewing machine comprises the steps that a sewing needle assembly sews a rotating foldedlayer, and a rotating pressure wheel is arranged at the side of the sewing needle assembly to arrange the outer layer of the folded layer, wherein if the circumference of the outer layer of the folded layer is larger than that of the inner layer of the folded layer, the rotation speed of the set pressure wheel is higher than that of the folded layer. The sewing control method of the sewing machine has the advantages that by arranging the rotating pressure wheel at the side of the sewing needle assembly to arrange the outer layer of the folded layer, when the length of the outer layer is larger than that of the inner layer, the rotation speed of the pressure wheel is set to be higher than the traveling speed of the folded layer, in this way, the pressure wheel with the high rotation speedcan slightly move the outer layer relative to the inner layer in the traveling direction of the folded layer, thereby more evenly integrating the extra part of the outer layer into sewing of each needle, so that folds of the sewn folded layer are very uniform, and the sewing quality is high.

Owner:张之鹏

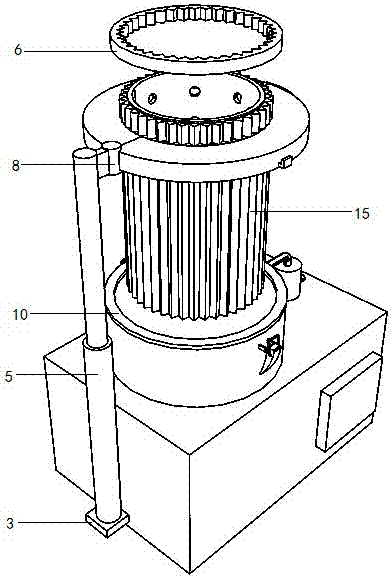

Integral molding barrel bag production device and production method

InactiveCN107599503BRealize the heating effectQuality improvementBag making operationsPaper-makingPetroleum engineering

The invention discloses an integrally formed barrel-shaped bag production device and a production method, and relates to the technical field of an integrally formed barrel-shaped bag production device and a production method. It includes a constant temperature oil bath, an air pump, a support plate, and a storage box are respectively fixed on the outer wall of the constant temperature oil bath; the air pump communicates with the inner barrel of the constant temperature oil bath; a vertical upward pole is fixed on the support plate; A beam-shaped ring is placed inside; the beam-shaped ring is an internal gear structure; a positioning device is fixed on the upper part of the pole. The invention has the beneficial effects that: it can produce an integrally formed barrel-shaped bag, and the produced barrel-shaped bag is thick on the top and thin on the bottom, is not easy to be damaged, and has a smooth surface and is convenient to use.

Owner:郑文涵

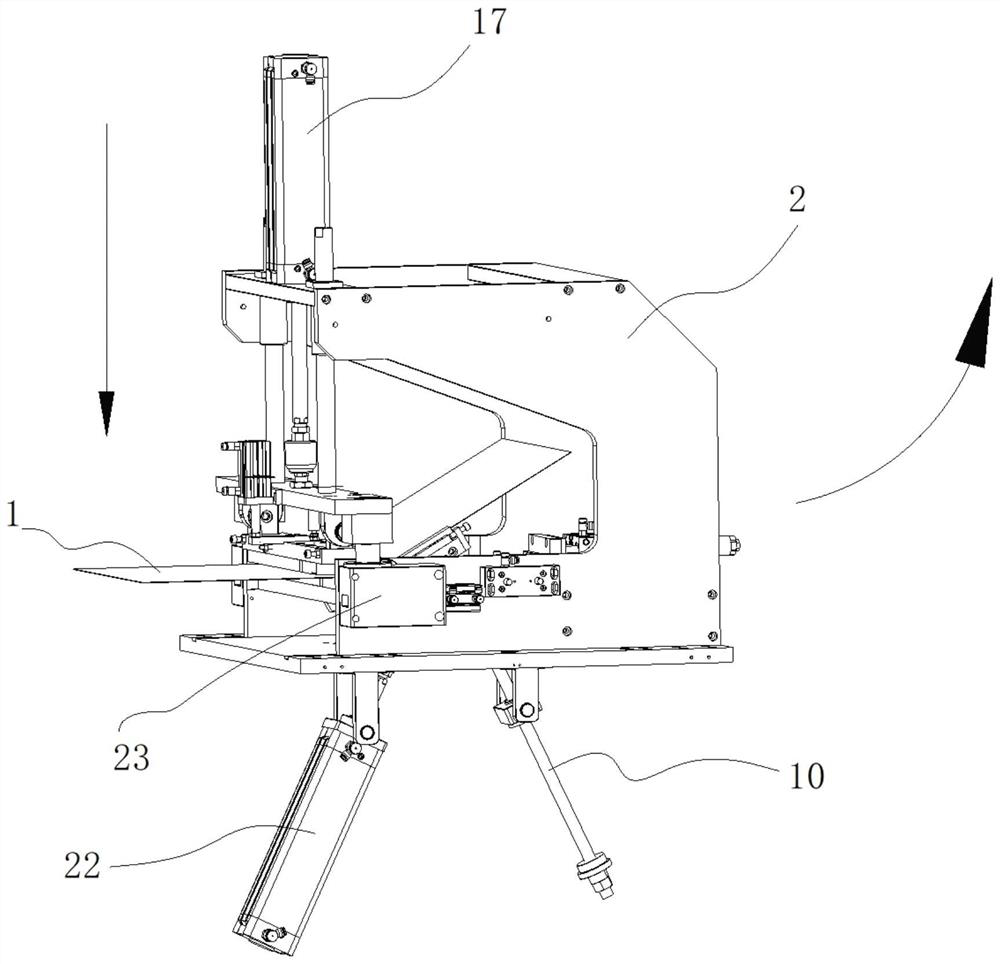

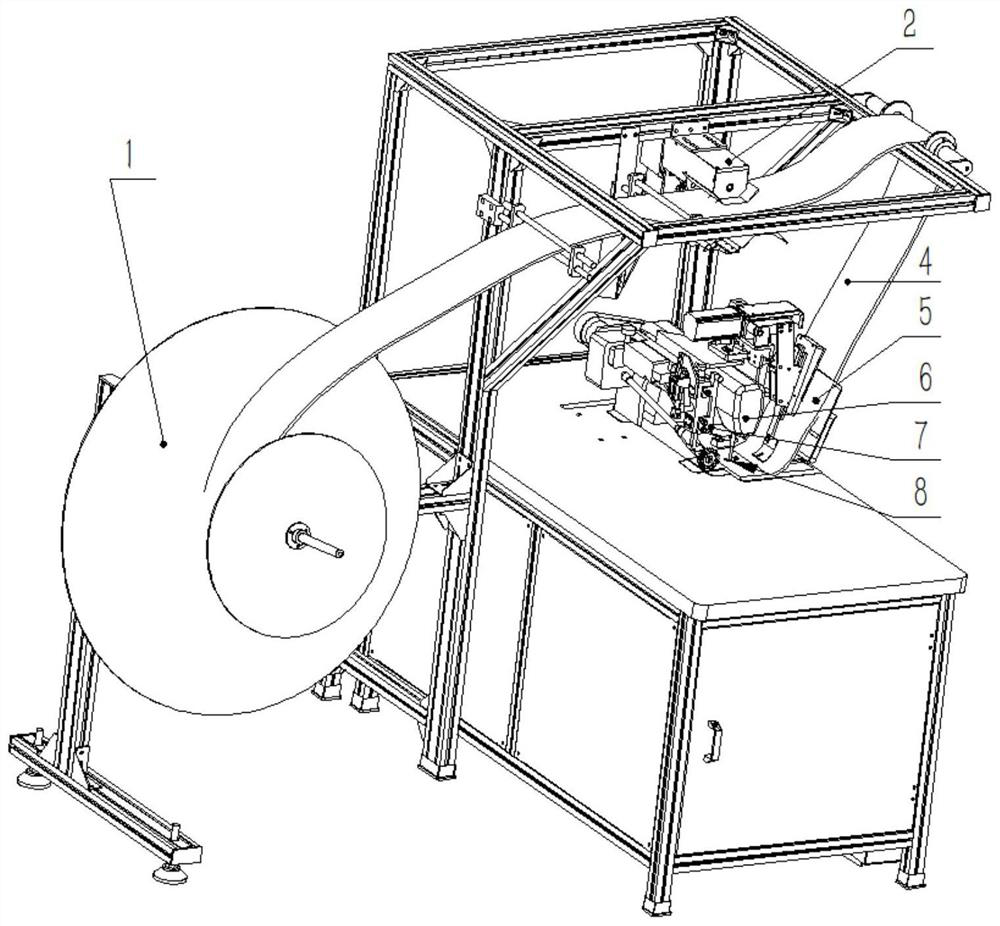

Automatic wrinkling machine for double-layer mattress foxing

PendingCN114232230ASynchronous deliveryGood effectWork-feeding meansSewing-machine control devicesEngineeringNonwoven fabric

The invention discloses a double-layer mattress foxing automatic wrinkling machine which comprises a discharging device, the discharging device is composed of a main frame and a discharging frame, the discharging frame is installed on one side of the main frame, a cloth feeding device is installed at the top of the main frame, a sewing machine head is installed in the middle of the main frame, and a wrinkling device, a traction device and a machine head presser foot are arranged on the sewing machine head. The wrinkling device is installed on one side of the sewing machine head, and a main shaft of the wrinkling device is connected with a rotating shaft of the sewing machine head through a belt. Limiting rods are symmetrically installed on the side, close to the discharging frame, of the top of the main frame, and a material supporting roller is installed on the side, away from the discharging frame, of the top of the main frame. The whole large non-woven fabric and the fabric are sewn through the sewing machine, when the non-woven fabric and the fabric reach the corner position, the machine can conduct automatic corner sewing till four corners are completed, one-time forming is achieved, the process can be completed only by one person, and the advantages of being high in speed, high in production efficiency, uniform in wrinkling, good in effect, capable of achieving data control, accurate and efficient are achieved.

Owner:广州喜登堡床垫机械有限公司

A kind of collecting and releasing device and technology for collecting and releasing gall mosquitoes of wild rice stem rust fungus

ActiveCN111418555BEfficient collectionThe method of collecting the chrysalis gall midge pupae is efficientInsect catchers and killersFisheryAlbugo candida

The invention discloses a collection and release device for gall midges of wild rice stem rust fungus, which includes a pupa collection device and a release device. Both the pupa collection device and the release device include transparent corrugated plastic PP boards, and the pupa collection device also includes a transparent plastic box body and a box cover. , moisturizing gauze, transparent corrugated plastic PP board, the transparent corrugated plastic PP board is detachably connected to the inner wall of the box through the connecting component; the release device also includes a holding box, a cover body, an isolation gauze, and moisturizing gauze. The collecting and releasing device and method of the present invention are extremely efficient, simple, easy to operate, labor-saving and time-saving.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

A combination method of high-temperature creasing and electric embroidery cutting for shoe production and shoes

The invention provides a high-temperature-crumpling electrical-embroidering cutting and assembling method used for manufacturing shoes and the shoes. The high-temperature-crumpling electrical-embroidering cutting and assembling method comprises the following steps: pressing dense chiffon into a whole piece of uniform crumpled yarn by adopting a high-temperature-crumpling method; arranging the crumpled part of the whole piece of crumpled yarn to be uniform and tidy, and then fixing the whole piece of crumpled yarn by adopting a clip; carrying out electrical-embroidering on the whole piece of crumpled yarn so that the needed part shape is formed, and embroidering detachment-preventing threads on the peripheries of the parts; embroidering the corresponding size on each part; and assembling the part with the other parts according to the positions of the detachment-preventing threads on the peripheries, attaching the formed part to the lining, and carrying out stitching. The shoes are prepared by adopting a process comprising the high-temperature-crumpling electrical-embroidering cutting and assembling method. According to the method, a fabric is crumpled, and then the crumpled fabric is subjected to electrical-embroidering sizing according to the part shape, the sized fabric is cut, the cut parts are assembled, and then the size is electrically-embroidered to the crumpled fabric; the whole process is simple, and the crumpling is uniform and flat; the electrical-embroidering has the size, therefore, a worker can easily distinguish the size during the operation, and thus the cutting and assembling accuracy and the crumpling uniformity can be effectively improved.

Owner:GUANGZHOU RUNKAI IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com