Integral molding barrel bag production device and production method

A production device and molding barrel technology, which is applied in packaging, bag making, transportation and packaging, etc., can solve the problems of wrinkles, poor integrity, and space occupied at the bonding point, so as to ensure smooth molding, improve quality, and facilitate the production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

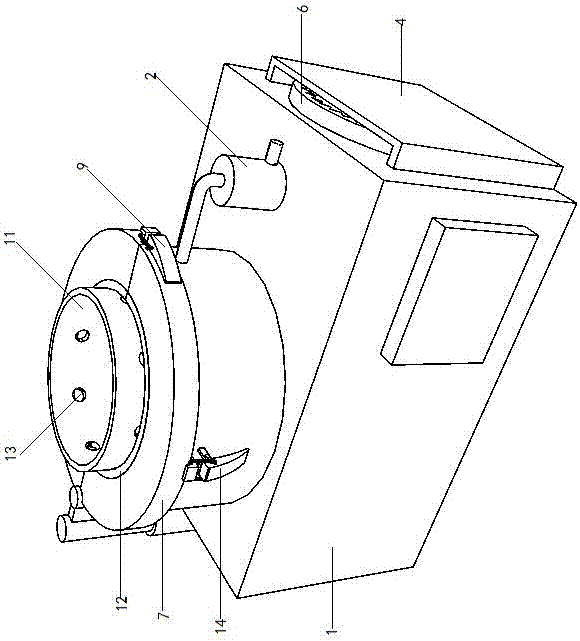

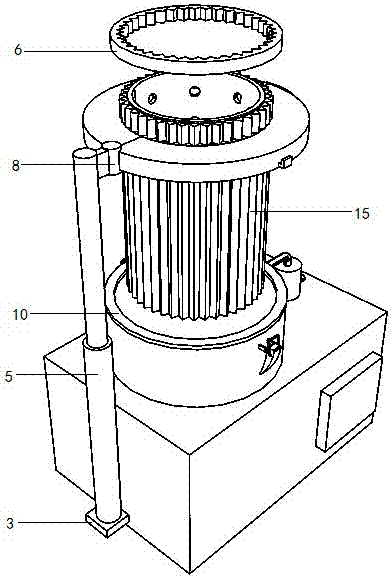

[0027] like Figure 1-2 As shown, the integrally formed barrel-shaped bag production device and production method include a constant temperature oil bath pot 1, an air pump 2, a support plate 3, and a storage box 4 are respectively fixed on the outer wall of the constant temperature oil bath pot 1; the air pump 2 and the constant temperature oil bath The inner barrel of the pot 1 is connected; the support plate 3 is fixed with a vertically upward support rod 5; a beam-shaped ring 6 is placed in the storage box 4; the beam-shaped ring 6 is an internal gear structure; the upper part of the support rod 5 is fixed with a positioning device; the positioning device includes a top cover coaxially arranged with the inner barrel of the constant temperature oil bath 1; the top cover is composed of two semi-circular clamping plates 7 that cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com