Double-layer elastic anti-crumple jacquard fabric and manufacturing technology thereof

A production process, double-layer technology, applied in the direction of digging fabrics, fabric surface trimming, textiles, etc., can solve the problems of reducing production efficiency, fabrics feel hard, unfavorable environmental protection, etc., to reduce production costs, simplify process flow, The effect of good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

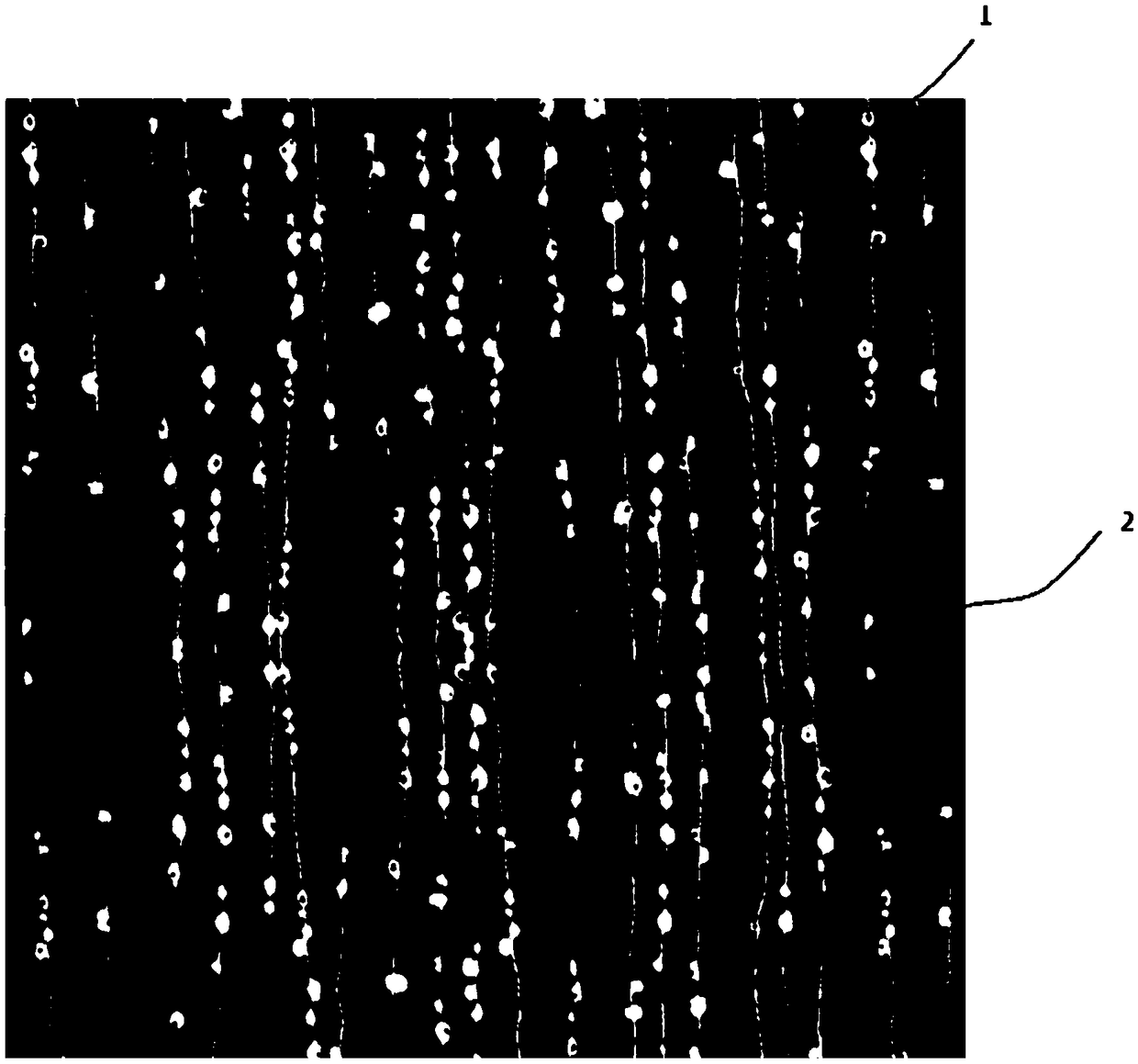

Image

Examples

Embodiment 1

[0032] The manufacturing process of a kind of double-layer elastic imitation crumpled jacquard fabric of the present embodiment comprises the following steps:

[0033] (1) Gray fabric weaving: 75D black low elastic yarn and 75D white polyester yarn in the warp direction (accounting for 55% by mass), 75D black polyester cationic yarn and 75D white high elastic yarn in the weft direction (accounting for 45% by mass), Weaving into gray fabric through double-layer jacquard weave;

[0034] (2) Dyeing: dye the gray cloth into the overflow tank, high-pressure dyeing, and use cationic dyes; control the temperature of the cationic dyes at 90°C and keep warm for 30 minutes;

[0035] (3) Reduction cleaning and dehydration: fully wash with water after dyeing, perform reduction cleaning when dyeing dark colors, and then dehydrate;

[0036] (4) Shaping: add a softener when shaping; control the temperature of the above gray cloth to 180°C when shaping, and adjust the speed to 40 m / min;

[...

Embodiment 2

[0040] The manufacturing process of a kind of double-layer elastic imitation crumpled jacquard fabric of the present embodiment comprises the following steps:

[0041] (1) Gray fabric weaving: 85D blue low elastic yarn and 85D white polyester yarn in the warp direction (accounting for 60% by mass), 85D blue polyester cationic yarn and 85D white high elastic yarn in the weft direction (accounting for 40% by mass) Silk, weaved into gray cloth through double-layer jacquard weave;

[0042] (2) Dyeing: dye the gray cloth into the overflow tank, high-pressure dyeing, and use cationic dyes; control the temperature of the cationic dyes at 100°C and keep warm for 40 minutes;

[0043] (3) Reduction cleaning and dehydration: fully wash with water after dyeing, perform reduction cleaning when dyeing dark colors, and then dehydrate;

[0044] (4) Shaping: Add softener when shaping; control the temperature of the above gray cloth to 185°C when shaping, and adjust the speed to 42 m / min;

[...

Embodiment 3

[0048] The manufacturing process of a kind of double-layer elastic imitation crumpled jacquard fabric of the present embodiment comprises the following steps:

[0049] (1) Gray fabric weaving: 100D red low elastic yarn and 100D white polyester yarn in the warp direction (accounting for 65% by mass), 100D red polyester cationic yarn and 100D white high elastic yarn in the weft direction (accounting for 35% by mass), Weaving into gray fabric through double-layer jacquard weave;

[0050] (2) Dyeing: dye the gray cloth into the overflow tank, high-pressure dyeing, and use cationic dyes; control the temperature of the cationic dyes at 110°C and keep warm for 50 minutes;

[0051] (3) Reduction cleaning and dehydration: fully wash with water after dyeing, perform reduction cleaning when dyeing dark colors, and then dehydrate;

[0052] (4) Shaping: Add softener when shaping; control the temperature of the above gray cloth to 190°C when shaping, and adjust the speed to 45 m / min;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com