Patents

Literature

56results about How to "The production process is environmentally friendly and pollution-free" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

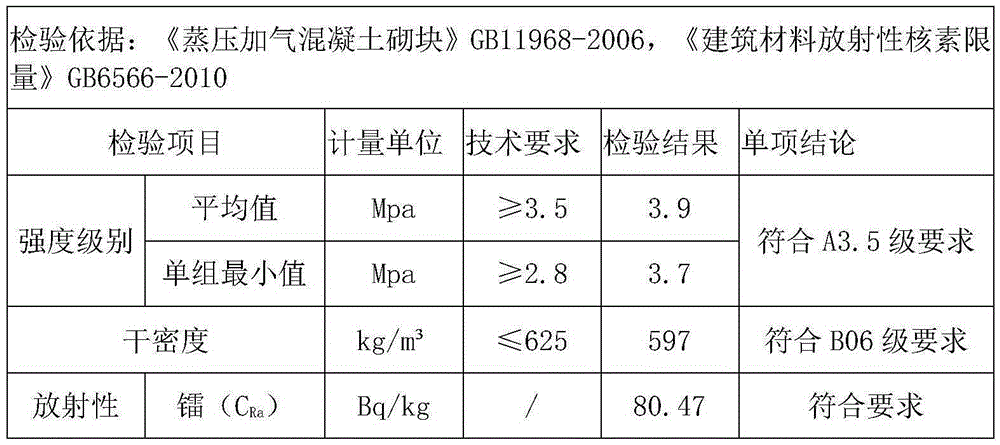

Red mud autoclaved aerated concrete building block and preparation method of red mud autoclaved aerated concrete building block

The invention discloses a red mud autoclaved aerated concrete building block and a preparation method of the red mud autoclaved aerated concrete building block. The building block is prepared from the following ingredients in parts by weight: 5 to 15 parts of red mud, 15 to 60 parts of pulverized fuel ash, 2 to 8 parts of plaster, 10 to 35 parts of quicklime, 5 to 10 parts of concrete, 0.01 to 0.03 parts of aluminum powder and water. The red mud is used for replacing phosphorus slag and undergoes a series of reactions with raw materials such as the pulverized fuel ash, the plaster, the quicklime, the concrete and the aluminum powder to prepare the aerated concrete building block; the product weight is light; the strength is high; the stability is good; the heat conductivity coefficient is low; the performance is excellent; the problem that the red mud cannot be easily and synthetically utilized is solved; the stored red mud can be fast digested; the goal of saving national resources is achieved, a lot of soil is also restored; in addition, the production process is environment-friendly and has no pollution; a new path is opened up for the comprehensive utilization of the red mud.

Owner:贵州源隆新型环保墙体建材有限公司

Angelica keiskei health care tenacity biscuit

InactiveCN103503960AThe production process is environmentally friendly and pollution-freeFull of nutritionDough treatmentBakery productsManufacturing technologyJasminum fruticans

The invention relates to an angelica keiskei health care tenacity biscuit. The biscuit is composed of, by weight, 150-160 parts of plain flour, 0.8-1.1 parts of yeast powder, 10-12 parts of cucumber seed powder, 8-12 parts of black fungus powder, 20-30 parts of white sesame seed, 10-13 parts of angelica keiskei, 12-14 parts of kelp, 2-3 parts of fructus gardeniae, 3-4 parts of chrysanthemum, 2-3 parts of bulbus fritillariae cirrhosae, 3-4 parts of jasmine, 2-3 parts of bunge pricklyash leaf, 2-3 parts of uncaria root and the like. According to the angelica keiskei health care tenacity biscuit, the manufacturing technology is friendly to environment, free of pollution and rich in nutrition. Powder nutritional agents such as cucumber seed powder are added into the biscuit and the good effect of health care is achieved. Meanwhile, extracts of traditional Chinese medicinal materials which include fructus gardeniae and bulbus fritillariae cirrhosae are specifically added, the efficacies of protecting the liver and clearing heat are achieved and the health of the human body is benefited.

Owner:XUZHOU FENGRUN BIOLOGICAL ORGANIC FERTILIZER TECH DEV CO LTD

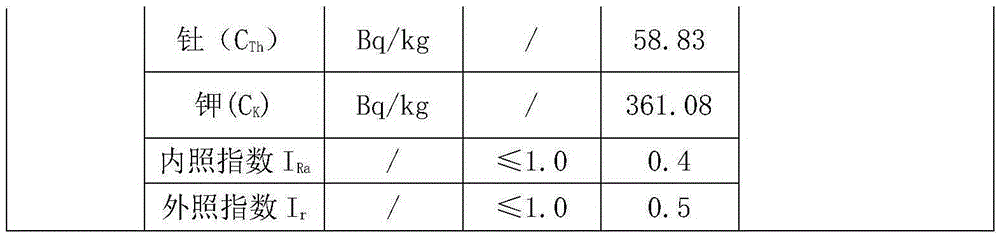

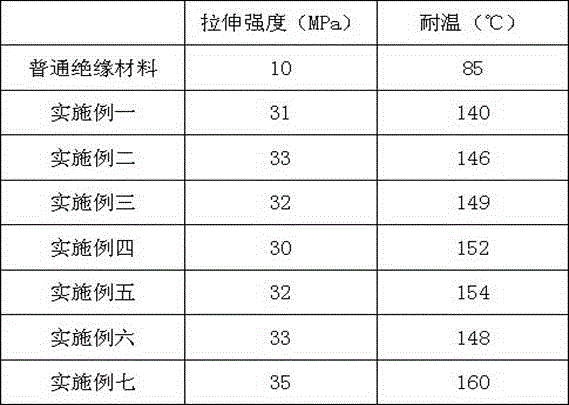

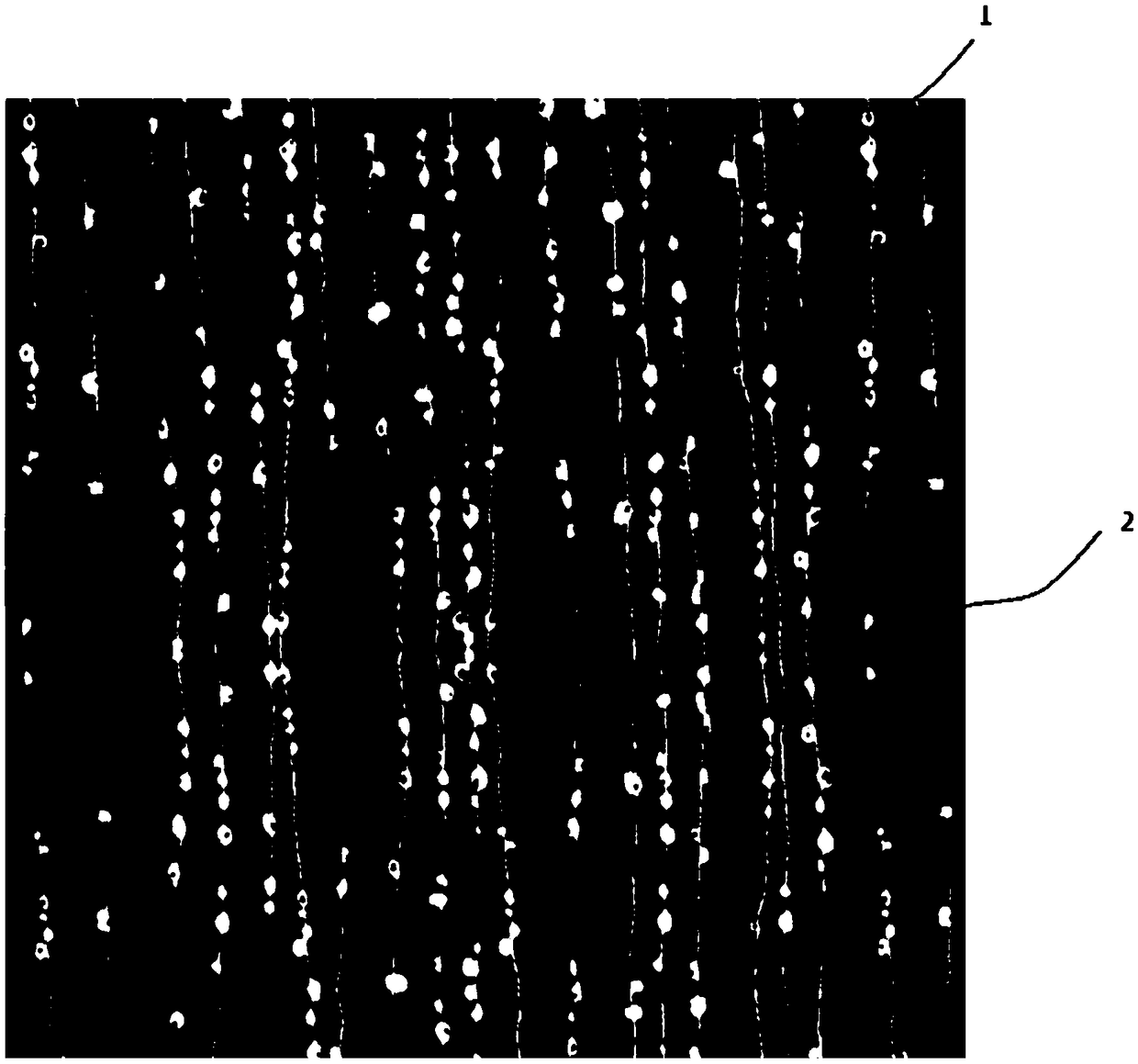

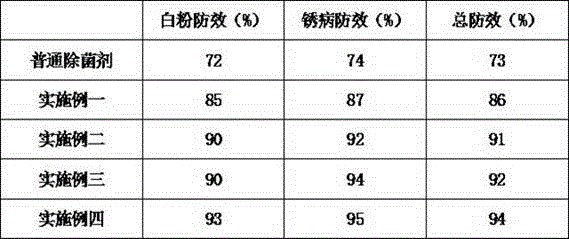

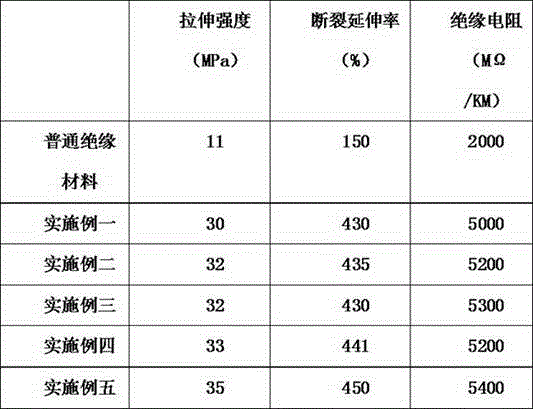

High-heat-resistance insulating composite and preparation method thereof

The invention discloses high-heat-resistance insulating composite and a preparation method thereof. The insulating composite comprises according to parts by weight: 30-40 parts of epoxy resin, 10-20 parts of polytetrafluoroethylene, 10-20 parts of polypropylene enhanced fiber 4-10 parts of silica powder, 10-25 parts of nano zinc oxide, 10-15 parts of nano calcium carbonate, 3-8 parts of silane coupling agent, 10-20 parts of nano aluminum oxide, 5-10 parts of dibenzoyl peroxide, and 7-12 parts of a plasticizer. The insulating composite is simple to manufacture, a manufacturing process is environment-friendly and pollution-free, the manufactured insulating composite is anticorrosive, damp-proof and high-temperature-resistant and flame-retardant, has good mechanical and electrical properties and is suitable for the preparation of power cables.

Owner:HENAN YAAN ELECTRICAL INSULATION MATERIAL PLANT CO LTD

High-impregnation-resistance enamelled wire and making process thereof

InactiveCN105925161AExtended service lifeGood impregnation resistanceFireproof paintsAnti-corrosive paintsBisphenolPolytetrafluoroethylene

The invention discloses a high-impregnation-resistance enamelled wire and a making process thereof. The high-impregnation-resistance enamelled wire mainly comprises, by mass, 10-20 parts of bisphenol-A epoxy resin, 12-17 parts of polyamide resin, 7-12 parts of butyl rubber, 1-5 parts of isocyanate, 20-25 parts of hydroxyl resin, 7-12 parts of polytetrafluoroethylene, 3-8 parts of a reactive diluent, 10-15 parts of superfine zinc oxide, 12-17 parts of nanoscale silicon micro powder, 3-6 parts of white carbon black, 10-15 parts of polyacrylate, 2-7 parts of titanium dioxide, 5-12 parts of molybdenum titanium powder, 3-6 parts of dimethylethanolamine and 10-20 parts of polyimide. The making process is simple, environment-friendly and pollution-free, the enamelled wire made by the process is high in impregnation resistance, is resistant to corrosion, high temperature and impact and capable of adapting to severe environment and protecting a cable inside the enamelled wire, and service life of the enamelled wire is prolonged.

Owner:HENAN BOYE ELECTRIC MATERIALS CO LTD

Cable insulating material for ocean vessel and preparation method of cable insulating material

InactiveCN105885128AAntioxidant is goodImprove corrosion resistanceRubber insulatorsFiberCalcium silicate

The invention discloses cable insulating material for an ocean vessel and a preparation method of the cable insulating material. The cable insulating material comprises, by weight, 30-50 parts of natural rubber, 10-15 parts of nanoscale silicon dioxide, 5-15 parts of organosilicon crosslinking agent, 10-15 parts of nano modified resin, 8-15 parts of toughening agent, 7-15 parts of ascharite, 8-15 parts of dicumyl peroxide, 10-20 parts of methyl silicone oil, 10-20 parts of reinforced fibers, 20-30 parts of methacrylic acid modified nano silicon nitride, 15-25 parts of active calcium silicate, 7-16 parts of trichloroethyl phosphate, 10-15 parts of phenolic resin, 7-12 parts of silane coupling agent, 4-10 parts of white carbon black and 2-9 parts of plasticizer. The cable insulating material has the advantages that the preparation process is simple, environmentally friendly and free of pollution, the prepared cable insulating material for the ocean vessel is good in oxidization resistance, corrosion resistance, humidity resistance and flame retardance, and the service life of a cable for the ocean vessel is prolonged.

Owner:李文军

Plant fiber environmental protection decorative sheet

The invention discloses a plant fiber environmental protection decorative sheet. The decorative sheet is prepared from, by weight, 30-50 parts of carbon dust, 2-10 parts of resin, 5-20 parts of plant fiber, 1-4 parts of fire retardant, 1-5 parts of dispersing agent, 1-5 parts of zeolite powder, 2-6 parts of tea pole dregs, 5-15 parts of foaming control agent, 3-8 parts of CPE, 1-5 parts of yellow foaming agent, 1-5 parts of stearic acid, 2-7 parts of stabilizer, 30-50 parts of PVC, 20-50 parts of calcium powder, 10-20 parts of bamboo powder and 10-20 parts of bamboo ash. According to the plant fiber environmental protection decorative sheet, the preparing technique is very simple, the preparing process is environmentally protective and pollution free, and the prepared decorative sheet is capable of adsorbing and degrading hazardous substances such as sulfide, nitride, formaldehyde, benzene and phenol; meanwhile, the plant fiber environmental protection decorative sheet is low in production cost and good in economic benefits.

Owner:叶爱云

Composite wear resisting material and preparation process thereof

InactiveCN107034409AHigh compressive strengthImprove flexural strengthTitanium nitrideTitanium oxide

The invention discloses a composite wear resisting material and a preparation process thereof. The wear resisting material comprises the following components in parts by weight: 40-60 parts of waste steel, 10-20 parts of flake corundum, 5-15 parts of silicon carbide grains, 5-10 parts of ferrotitanium, 5-12 parts of silicon carbide, 8-15 parts of borax, 3-8 parts of zirconium silicate, 4-10 parts of aluminum nitride, 4-12 parts of titanium nitride, 3-8 parts of silicon micropowder, 1-5 parts of nanometer titanium oxide, 15-25 parts of toughening agent, and 10-20 parts of emulsifier. The preparation process is simple, environment-friendly, free of pollution and low in manufacturing cost; and the prepared wear resisting material is excellent in compressive strength, breaking strength and wear resistance, and is long in service life.

Owner:汪建军

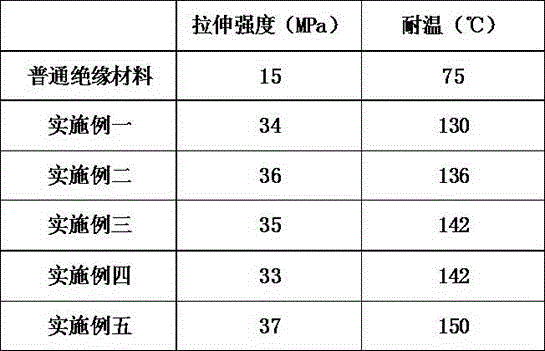

Hollow corn stalk brick building block and preparation method thereof

ActiveCN103467029AImprove stress resistanceStrong interactionSolid waste managementBuilding componentsBrickThermal insulation

The invention provides a hollow corn stalk brick building block. The hollow corn stalk brick building block comprises the following raw materials: 50-75wt% of corn stalks, 0.5-5wt% of a modifier, 15-35wt% of cement, 0.1-3wt% of a quick-drying agent and 5-20wt% of water. According to the hollow corn stalk brick building block, the corn stalks are taken as a raw material for preparing a building block, under the action of the modifier, the good interaction exists between each corn stalk and the cement, and a structure can be easily formed, so that the compression resistance and the water invasion property of the obtained hollow building block are improved; the obtained hollow corn stalk building block is applied to wall body buildings, so that a bearing structure, a thermal insulation structure and a maintenance structure of a wall body are completed by one step, the thermal insulation structure and the bearing structure are organically combined into a whole, the service life of the bearing structure and the service life of the thermal insulation structure are the same, and both the bearing and the thermal insulation are considered.

Owner:CHANGCHUN YUANYANG SPECIAL IND MATERIALS

Environment-friendly decorative plate

The invention discloses an environment-friendly decorative plate. The decorative plate comprises the following components in parts by weight: 20-40 parts of nano carbon powder, 3-10 parts of PVC resin, 10-25 parts of reinforced fibers, 1-5 parts of a flame retardant, 1-5 parts of a dispersing agent, 8-12 parts of polyethylene wax, 3-8 parts of waterborne polyurethane, 5-15 parts of a foaming regulator, 3-8 parts of stearic acid, 3-9 parts of sodium fluosilicate, 5-12 parts of titanium dioxide, 3-10 parts of a stabilizer, 25-40 parts of ground calcium carbonate, 15-30 parts of calcium sulfate whiskers, 10-25 parts of silica fume and 10-25 parts of diatomite. The environment-friendly decorative plate disclosed by the invention has the advantages that the preparation technology is simple, the production process is environment-friendly and pollution-free, the obtained decorative plate can adsorb and degrade harmful substances such as sulfide, nitride, formaldehyde, benzene and phenol, the production cost is low, the economic benefit is good, and the decorative plate also has wear-resistant and pressure-proof effects and long service life.

Owner:MAANSHAN RUNQI NEW MATERIAL SCI & TECH

Making method of full shading curtain

PendingCN110256701AGood UV resistance and anti-aging abilityThe production process is environmentally friendly and pollution-freeCarbon blackTitanium dioxide

The invention discloses a making method of a full shading curtain. The making method includes the following steps: a step of processing of base cloth; a step of preparation of a black and white shading film, wherein the black and white shading film comprises, by mass, 30-50 parts of polyurethane, 8-12 parts of low-density polyethylene, 20 parts of carbon black, 30-50 parts of an opalizer, 8 parts of titanium dioxide, 10-20 parts of nano gelatin beads and 5-8 parts of phenyl salicylate; and a step of hot pressing, namely a step of coating one side of the base cloth with acrylic resin and carrying out hot pressing at 130-180 DEG C to combine the black and white shading film with the base cloth. The making method of the full shading curtain related by the invention uses a method of extrusion blow molding to produce the black and white shading film and combines the black and white shading film with the base cloth after oil removal and decontamination treatment to make the whole production process environmentally friendly and pollution-free. Moreover, the phenyl salicylate and the titanium dioxide are used in the black and white shading film to make the black and white shading film have good ultraviolet resistance and aging resistance. Furthermore, the full shading curtain has good effects of heat insulation and sound insulation.

Owner:HAINING SANLIAN TEXTILE CO LTD

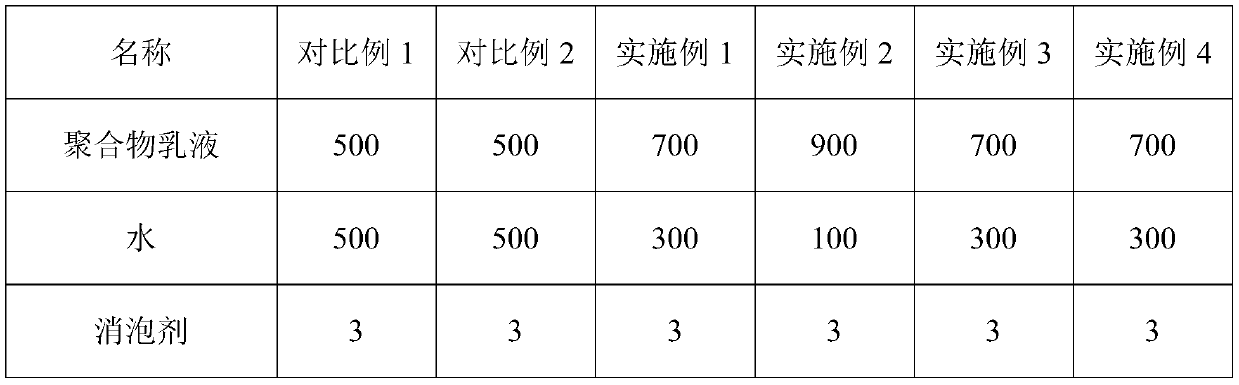

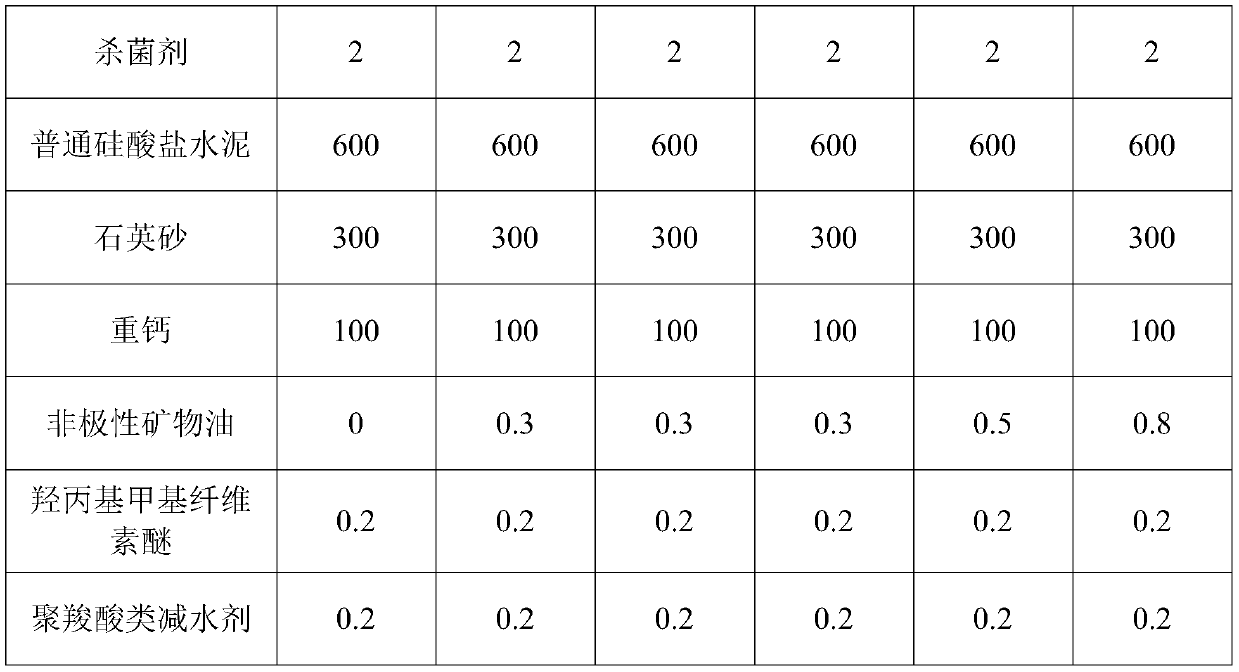

Polymer cement waterproof slurry and preparation method thereof

The invention discloses a polymer cement waterproof slurry and a preparation method thereof. The polymer cement waterproof slurry comprises a liquid material and a powder material; the liquid materialis prepared from the components:300-900 parts of a polymer emulsion, 0.5-4 parts of a defoamer, 0.5-4 parts of a bactericide and 100-600 parts of water; the powder material is prepared from the components:500-700 parts of cement, 200-400 parts of sand, 50-150 parts of a filler, 0.1-1 part of non-polar mineral oil, 0.1-5 parts of a water-retaining agent and 0.1-5 parts of water reducing agent; thepolymer emulsion is an acrylic emulsion and / or a styrene acrylate copolymer emulsion; and the weight ratio of the polymer emulsion and the water is (1.2-9) to 1. According to the polymer cement waterproof slurry, the amount of the water is lowered by improving the amount of emulsion in the liquid material, the dust removal effect of the product is relatively more excellent, and the bond strengthloss is reduced with the addition of the same mineral oil.

Owner:东方雨虹民用建材有限责任公司

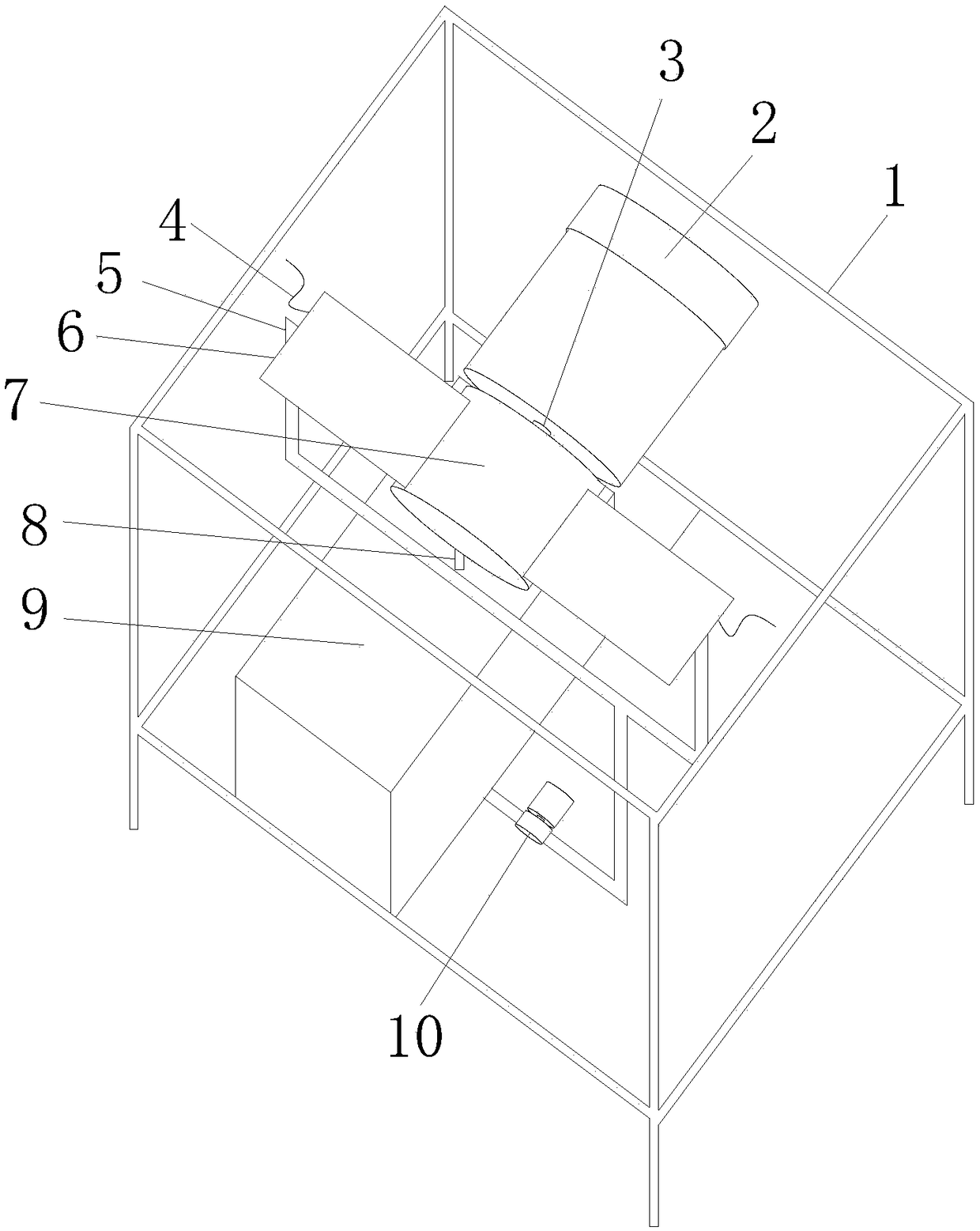

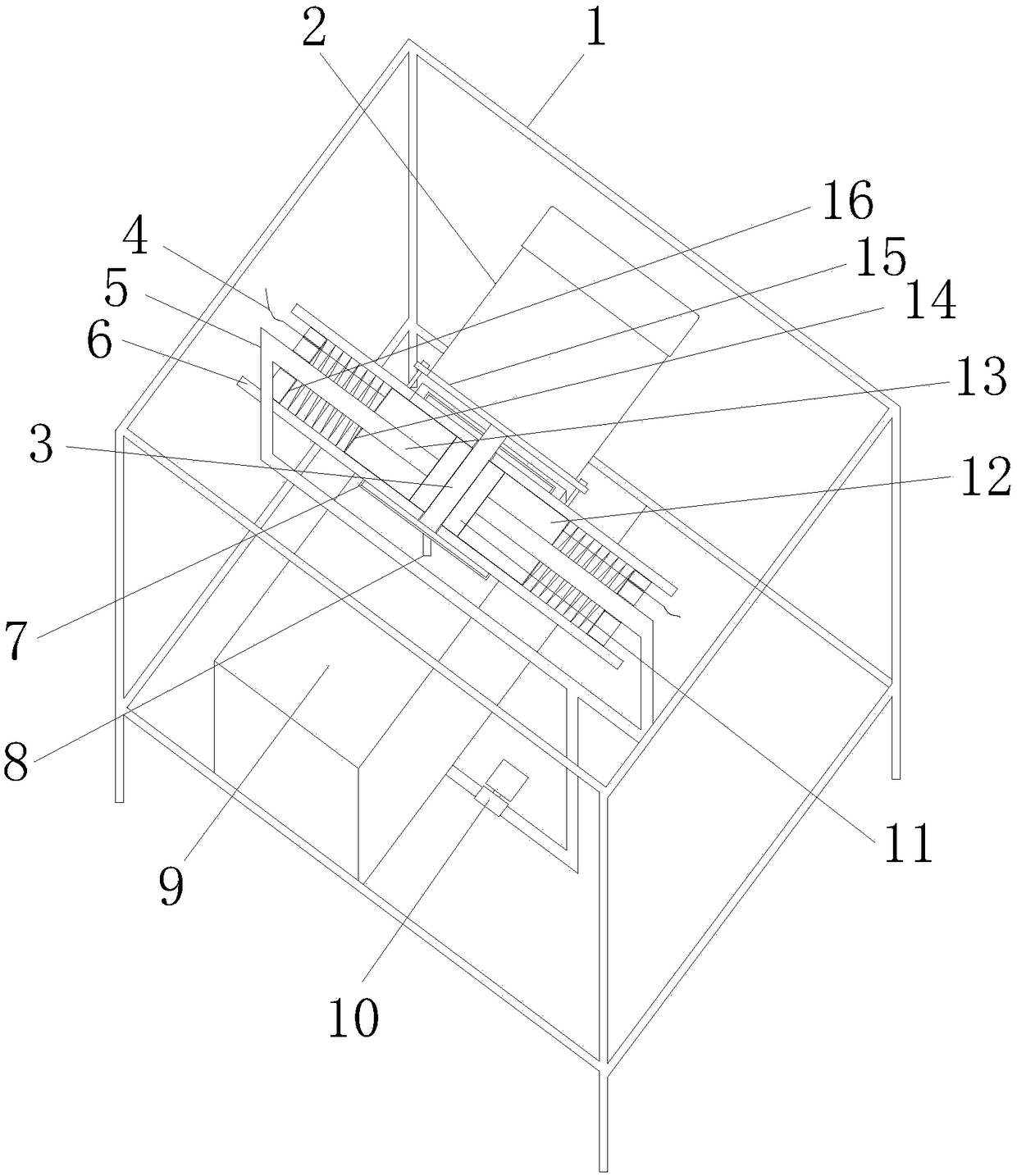

Mechanical device for continuously producing graphene

InactiveCN108238598AImprove production and efficiencyReduce production energy consumptionGrapheneMotor shaftContinuous production

The invention discloses a mechanical device for continuously producing graphene. The mechanical device for continuously producing graphene comprises a frame, wherein a motor and a container are arranged inside the frame, the motor and the container are fixedly connected by virtue of a flange, the motor is provided with a motor shaft, the motor shaft penetrates through the interior of the container, a graphite cylinder is arranged at one end, arranged inside the container, of the motor shaft, graphite block channels are arranged at the two sides of the container respectively, a graphite block is arranged at one side, close to the graphite cylinder, inside each graphite block channel, a spring is arranged outside each graphite block, a spring baffle is arranged outside each spring, a throughhole is formed in the graphite cylinder, one end, far away from the graphite cylinder, of the through hole is fixedly connected with a pipeline, and each graphite block is also provided with a wire.The mechanical device for producing the graphene can effectively improve graphene production efficiency and yield, reduces production energy consumption and can realize continuous production of graphene separation and purification and is reasonable in structure and easy to use, thereby guaranteeing that a production process of graphene is environmentally friendly and free from pollution.

Owner:上海地霸电子科技有限公司

Preparation method of compound microorganism fermentation forage feed

InactiveCN106212853AHigh nutritional valueLong-term consumptionAnimal feeding stuffBiotechnologyDisease

The invention discloses a preparation method of a compound microorganism fermentation forage feed. The forage feed is prepared from the following components in parts by weight: 50 to 70 parts of mixed forage, 10 to 20 parts of a biological leavening agent, 5 to 15 parts of a mildew preventive and 8 to 15 parts of a degerming preservative, wherein the mixed forage consists of leymus chinensis, oat grass, legume, corn straws, sorghum stalks, wheat bran, alfalfa and bean cakes. The preparation process is simple, and the preparation process is environmentally friendly and pollution-free; the prepared forage feed is high in nutritional value; if an animal takes the feed for a long time, the immunity can be enhanced, and digestive system diseases can be reduced; meanwhile, the prepared feed can be stored for a long time, and no mildewing and rotting phenomena are caused.

Owner:GANSU AGRI UNIV

Environment-friendly power cable insulating material

InactiveCN105907031AThe production process is simpleIncrease elasticityPlastic/resin/waxes insulatorsPolypropylenePARAFFIN HYDROCARBONS

The invention discloses an environment-friendly power cable insulating material. The environment-friendly power cable insulating material is mainly prepared from, by weight, 15-20 parts of nano silicon dioxide, 15-25 parts of polyolefin, 10-15 parts of an organic silicon crosslinking agent, 10-15 parts of flame-retardant oil, 2-8 parts of a plasticizer, 25-35 parts of phenolic resin, 20-25 parts of polypropylene reinforced fibers, 15-25 parts of paraffin hydrocarbon oil, 2-8 parts of chitosan, 5-10 parts of polyolefin acid salt, 10-20 parts of a flexibilizer, 5-10 parts of silica powder, 20-30 parts of nano zinc oxide and 15-25 parts of polybutylene terephthalate. The environment-friendly power cable insulating material has advantages that the technical simplicity in preparation is realized, the preparation process is environment friendly and free of pollution, the prepared material guarantees efficacies of oxidation resistance, corrosion resistance, humidity resistance and flame retardation of power cables and improves elasticity and toughness of the power cables, and accordingly service lives of the power cables can be prolonged.

Owner:马鞍山纽盟知识产权管理服务有限公司

Bending-resistant insulating material and preparation method thereof

The invention discloses a bending-resistant insulating material and a preparation method thereof. The insulating material components include 15-25 parts of methyl vinyl silicone rubber, 20-30 parts of nitrile rubber, and an aluminum-titanium compound coupling agent in parts by weight. 10‑20 parts, 10‑15 parts of liquid barium zinc stabilizer, 4‑10 parts of adipic acid polyester, 10‑20 parts of phenolic resin, 15‑25 parts of nano silicon powder, 8‑15 parts of calcium lignosulfonate, 4-10 parts of nano-cerium oxide, 10-15 parts of white carbon black, 15-25 parts of anti-aging agent and 20-30 parts of reinforcing fiber. Elasticity and tenacity, high hardness, high density, the rubber tube made of this material is strong in pressure resistance, aging resistance and bending resistance.

Owner:李文军

Double-layer elastic anti-crumple jacquard fabric and manufacturing technology thereof

InactiveCN108642646ASimple processReduce manufacturing costHeating/cooling textile fabricsDyeing processYarnManufacturing technology

The invention provides a double-layer elastic anti-crumple jacquard fabric and belongs to the technical field of textile fabric production and processing. The fabric includes, by mass, 55%-65% of warpand 35%-45% of weft, wherein the warp adopts two kinds of 75D-100D low stretch yarn different in color, and the weft adopts two kinds of 75D-100D high stretch yarn and 75D-100D dacron cation silk which are different in color. The fabric is formed by weaving double-layer jacquard texture, and radial straight creases and a jacquard pattern are formed on the front surface of the fabric. The manufacturing technology of the double-layer elastic anti-crumple jacquard fabric includes the following steps of weaving and manufacturing of gray fabric, adoption of cation dyes for dyeing, reduction clearing, dewatering, shaping by a softening agent, examination, reeling and storage in a warehouse. A traditional crumpling technology is abandoned, and the same crumpling effect is achieved, so that the technology processes are simplified, and the production cost is greatly reduced. The fabric is soft in hand feeling and has uniform creases which are not likely to fade, and the straight creases can last forever. The production technology processes are environmentally friendly and free of pollution, and the fabric is high-end and safe and has a great market prospect.

Owner:绍兴水乡纺织科技有限公司

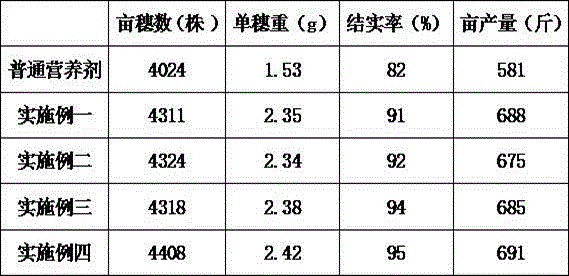

Novel wheat field composite bactericide and use thereof

InactiveCN106070357APromote growthSimple preparation processBiocidePlant growth regulatorsAchnatherum inebriansPlant disease

The invention discloses a novel wheat field composite bactericide and a use thereof. The composite bactericide comprises, by weight, 20-40 parts of sweet wormwood extract, 2-6 parts of a speader, 5-12 parts of naphthylacetic acid, 8-12 parts of brassinolide, 7-14 parts of high efficiency permethrin, 10-20 parts of a surfactant, 8-16 parts of a chlorone penetration enhancer, 5-10 parts of glycine, 10-20 parts of dichloromethane, 5-8 parts of Erodium stephanianum Willd., 10-20 parts of achnatherum inebrians, 5-10 parts of eucalyptus oleic acid, 1-4 parts of veratridine, 5-10 parts of humic acid and 10-20 parts of a polar organic solvent. The invention discloses the use of the bactericide in prevention and control of wheat diseases and promotion of wheat growth. The composite bactericide is prepared through simple processes, is environmentally friendly and does not pollute the environment. The novel wheat field composite bactericide is nontoxic, has high insecticidal effects, has a wide insecticidal spectrum and promotes wheat growth.

Owner:河南中天恒信生物化学科技有限公司

Insulating material for nuclear power plant and production technology thereof

InactiveCN106009102AGood acid and alkali resistanceImprove high temperature resistanceFiberPolyolefin

The invention discloses an insulating material for nuclear power plants and a production process thereof. The components of the insulating material include 30-50 parts of a rubber matrix, 15-30 parts of a flame retardant, 8-12 parts of a silane coupling agent, chlorinated 10‑20 parts of polyethylene, 1‑4 parts of UV absorber, 4‑10 parts of tin mercaptide, 5‑15 parts of toughening modifier, 15‑25 parts of polyolefin compound, 15 parts of polystyrene resin 30 parts, 8-15 parts of nano-scale silicon dioxide, 8-15 parts of cross-linked fluororesin, 10-15 parts of composite antioxidant and 10-30 parts of reinforcing fiber. The production process of the present invention is simple, and the production process is environmentally friendly and pollution-free , the prepared material has excellent acid and alkali resistance, high temperature resistance, flame retardancy, radiation resistance, long service life, and can be widely used as insulation material for nuclear power plant cables.

Owner:HENAN YAAN ELECTRICAL INSULATION MATERIAL PLANT CO LTD

Composite fungicide and preparation and application thereof

InactiveCN106818902APromote growthSimple preparation processBiocidePlant growth regulatorsAchnatherum inebriansEthephon

The invention relates to a composite fungicide. The composite fungicide is characterized by being prepared from the following materials in parts by weight: 20 to 30 parts of sweet wormwood herb extract, 3 to 9 parts of naphthylacetic acid, 0.01 to 0.02 part of isopropyl palmitate, 0.001 to 0.01 part of polyglycerol-3 ricinoleat, 3 to 6 parts of cinnamyl aldehyde, 2 to 7 parts of bacillus subtilis, 3 to 7 parts of physcion, 1 to 3 parts of ethephon, 10 to 15 parts of surfactant, 10 to 15 parts of dichloromethane, 10 to 15 parts of achnatherum inebrians, 3 to 6 parts of humic acid, 8 to 15 parts of pimacol and 2 to 8 parts of herba geranii. The invention has the following advantages: a preparation process disclosed by the invention is simple, the process of preparation is environment-friendly and pollution-free, and the prepared fungicide is non-toxic, has a high fungicidal effect and a broad fungicidal spectrum, and can also promote the growth of crops.

Owner:新昌县奥而特农业科技有限公司

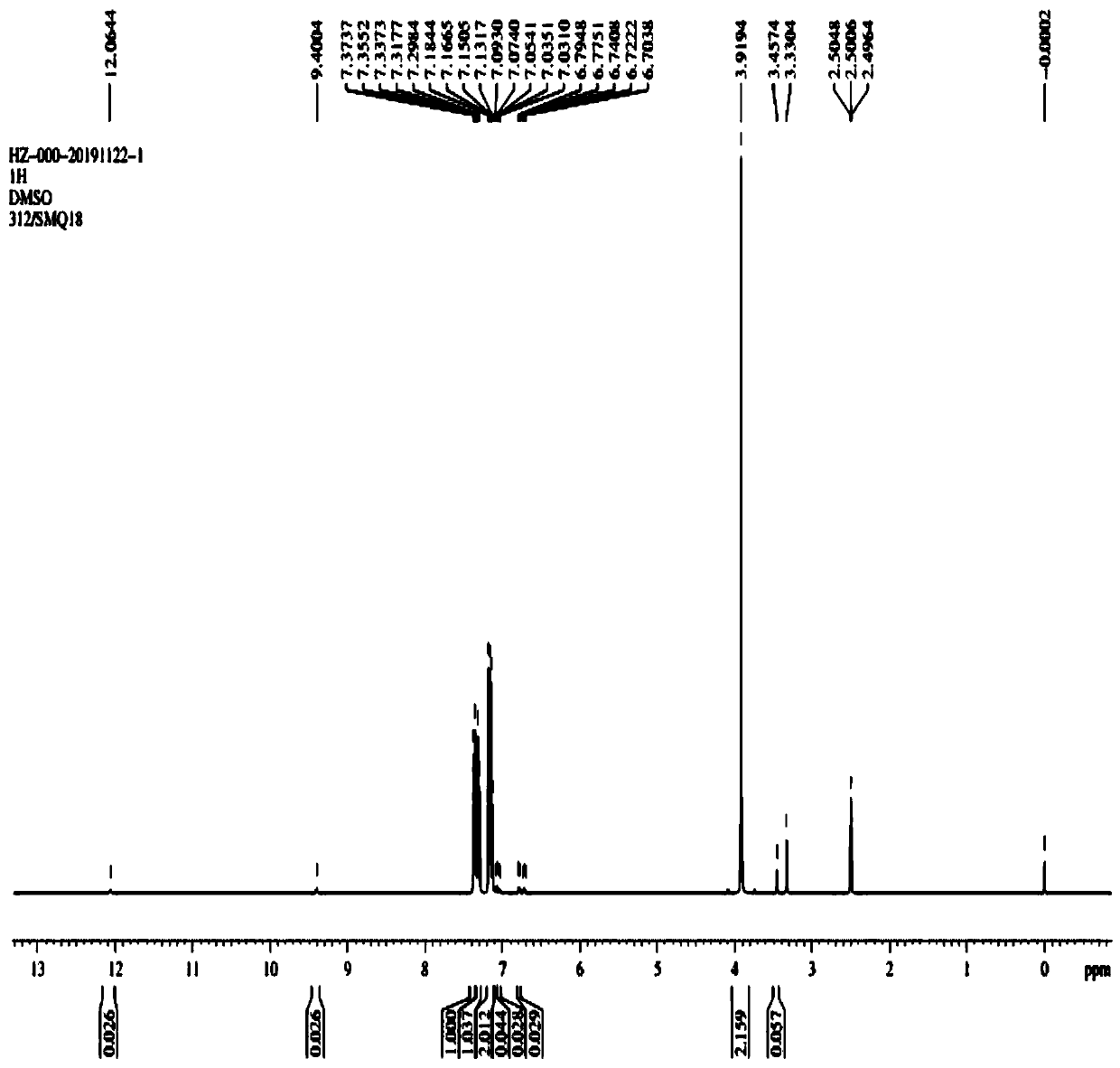

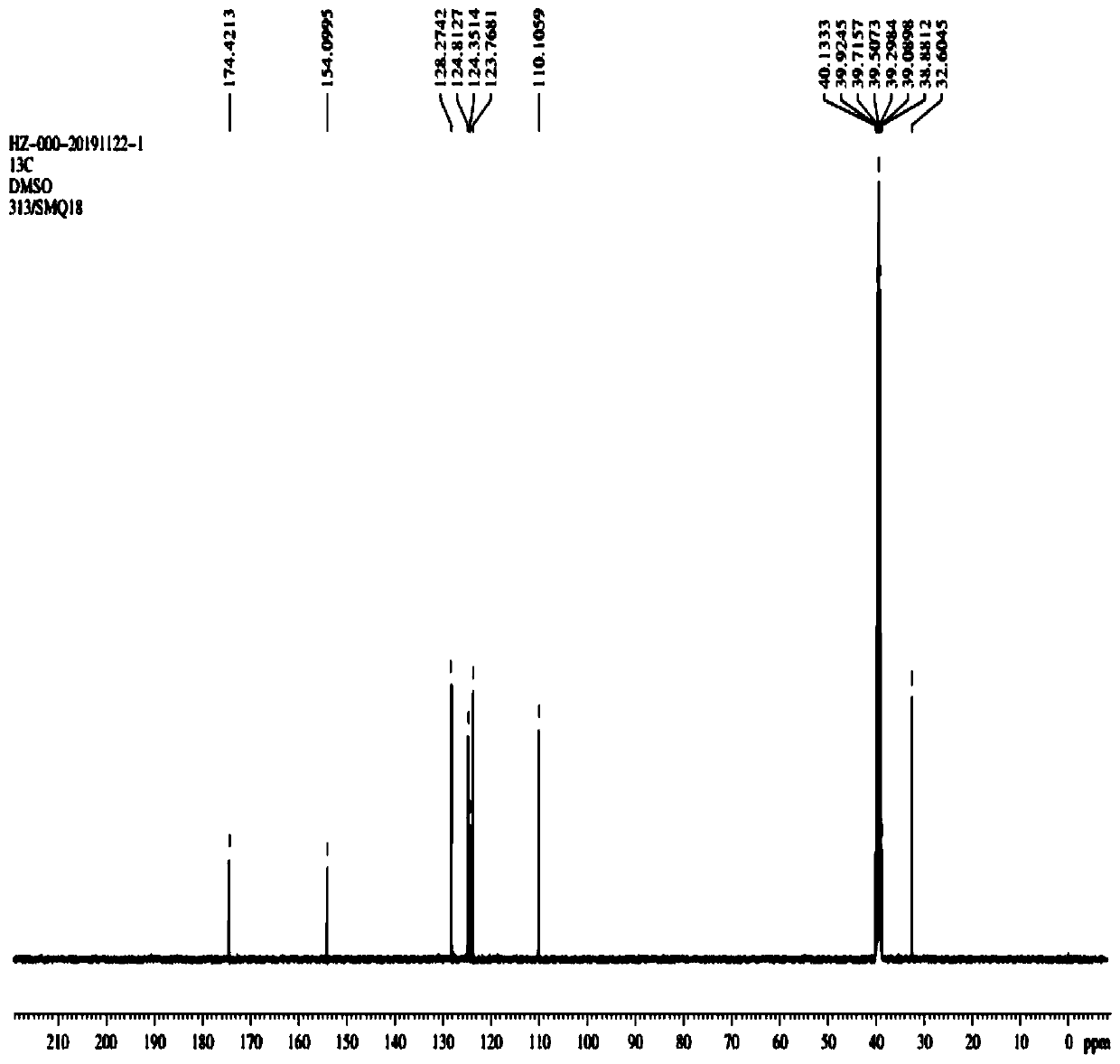

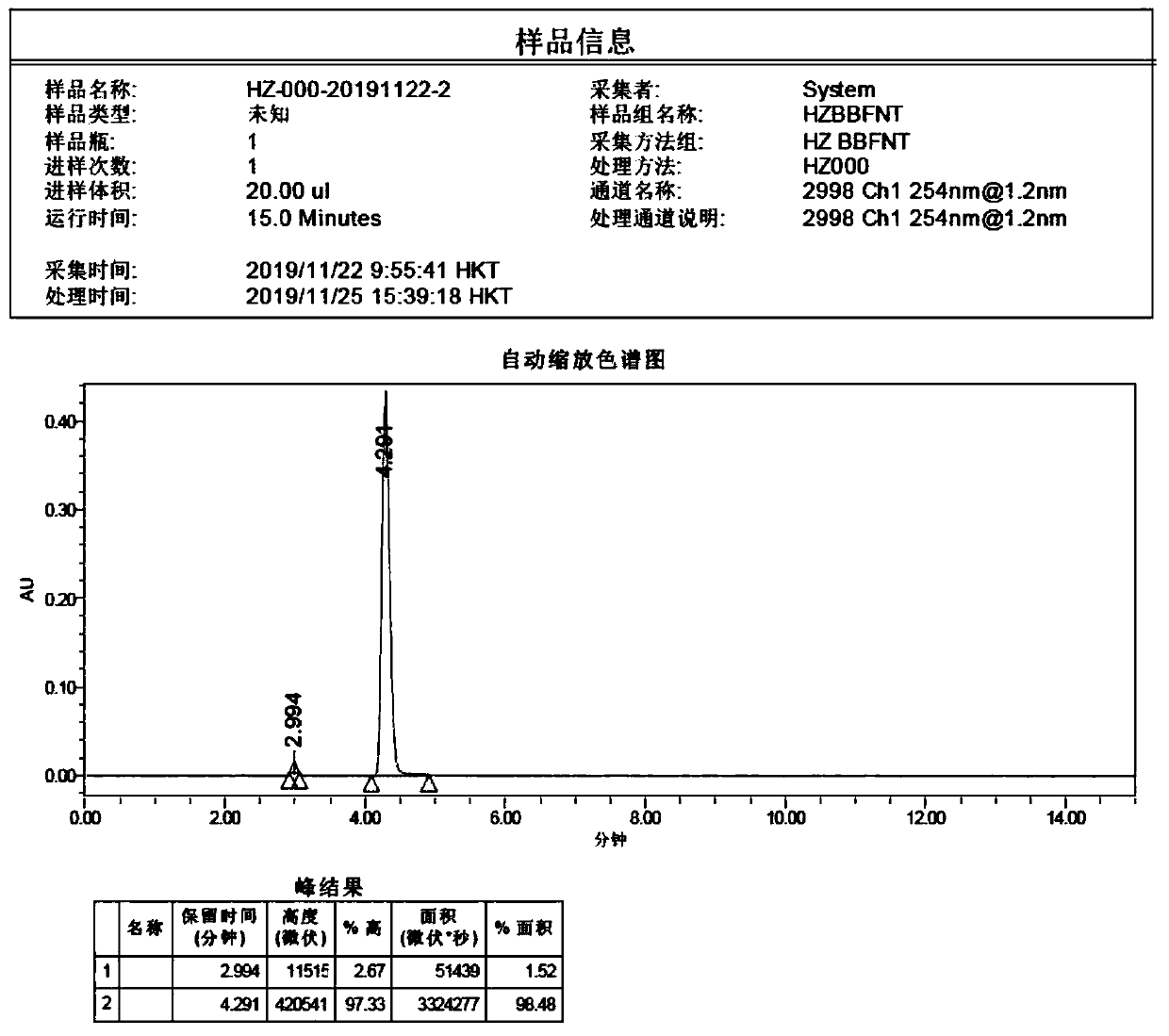

Method for synthesizing benzofuranone by taking o-chlorotoluene as raw material

ActiveCN111170971ALow priceThe production process is environmentally friendly and pollution-freeOrganic chemistryChemical recyclingOrtho-chlorotolueneProcess engineering

The invention provides a method for synthesizing benzofuranone by taking o-chlorotoluene as a raw material. According to the method, the target product benzofuranone is prepared by taking the easily-available o-chlorotoluene as the initial raw material, and the whole preparation process is mild in condition, high in yield and suitable for large-scale industrial production.

Owner:安徽中羰碳一工业技术有限责任公司

High-flame-retardancy composite calcium carbonate and preparation method thereof

InactiveCN106349760AOptimize the production processAdd high flame retardant performancePigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsChemistryOrganosilicon

The invention discloses high-flame-retardancy composite calcium carbonate and a preparation method thereof; the high-flame-retardancy composite calcium carbonate is prepared from calcium carbonate, unsaturated polyester resin, magnesium hydroxide, kaolin, styrene, organosilicon-modified acrylic resin, glycerol, pure benzene, isobutanol, a modifier, and suitable water; the preparation method of the high-flame-retardancy composite calcium carbonate includes the steps of (1) preparing premix for use; (2) preparing a mixed liquid; (3) preparing a modifier; (4) mixing the premix, the mixed liquid and the modifier, stirring well, grinding, drying, and crushing to obtain superfine powder. By combining the calcium carbonate with materials having good comprehensive properties, such as styrene, unsaturated polyester resin, magnesium hydroxide and organosilicon-modified acrylic resin, the production process is modified; by using the modifier and the like, high flame retardancy of the composite is effectively improved; the production process is simple, the production cycle is short, the quality is stable, the production cost is low, and the high-flame-retardancy composite calcium carbonate and the preparation method are high in applicable value.

Owner:中玺新材料(安徽)有限公司

Anti-oxidation coating for automobile storage box and preparation method of anti-oxidation coating

InactiveCN106280720AImprove antioxidant capacitySatisfy anti-corrosionCellulose coatingsAnti-corrosive paintsCorrosionRaw material

The invention discloses an anti-oxidation coating for an automobile storage box. The anti-oxidation coating is prepared from the raw materials of cellulosic resin, styrene-acrylic emulsion, ethylene resin, fluorocarbon resin, isocyanate, dispersing agent, catalyst, thickener, talcum powder, iron-titanium powder, butyl acetate, ethylene glycol, pure water and rosin-modified resin. A preparation method of the anti-oxidation coating comprises the following steps in sequence: (1) uniformly stirring corresponding raw materials; (2) preparing a mixed solution; (3) preparing coating mixed liquid; (4) grinding the coating mixed liquid, and filtering to obtain a finished product. The anti-oxidation coating has a flat, fine and smooth surface and high gloss retention, and is superior to ordinary materials on the aspects of tension strength and breaking elongation, so that the anti-oxidation coating can meet the use requirements of the automobile storage box on corrosion resistance, weather resistance and the like of box coating; the preparation method is simple, is low in cost, and is suitable for industrial batch production.

Owner:安徽班合拍卖服务有限公司

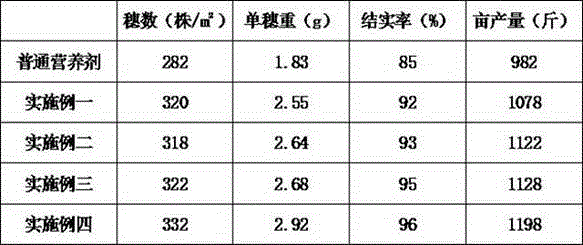

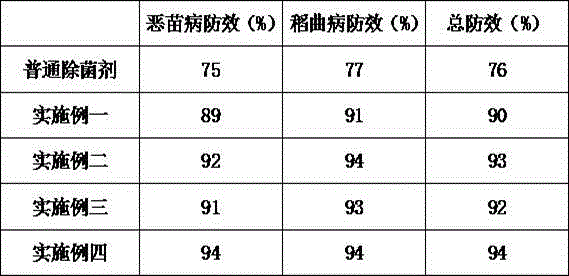

Novel rice field composite fungicide and application thereof

InactiveCN106106529AEfficient dewormingEffective insect repellentBiocidePlant growth regulatorsManufacturing technologyEthephon

The invention discloses a novel paddy field compound fungicide and application thereof. The compound fungicide includes 2-6 parts of cinnamaldehyde, 7-12 parts of surfactant NP-100, and 5-12 parts of azone enhancer in parts by weight. 3-8 parts of emodin methyl ether, 2-4 parts of ethephon, 1-5 parts of rice blast, 3-6 parts of Bacillus subtilis, 15-25 parts of alkyl biguanide fungicides, 10 parts of polar organic solvents ‑15 parts, 8‑16 parts of oligosaccharides, 2‑5 parts of thiamine, 2‑6 parts of humic acid, 7‑12 parts of sodium naphthalate, 8‑15 parts of diethyl aminoethyl hexanoate, the invention also discloses the bactericidal The application of the fungicide in the prevention and treatment of rice diseases and the promotion of rice growth, the preparation process of the invention is simple, the production process is environmentally friendly and pollution-free, and the prepared fungicide has efficient insecticide and insect control effects, and can also promote the growth and development of rice.

Owner:河南中天恒信生物化学科技有限公司

Environmentally-friendly disinfectant

InactiveCN106508990AEfficient removalSimple preparation processBiocideDisinfectantsDisinfectantBiology

The invention discloses an environment-friendly disinfectant including the following components by weight: 5-10 parts of castor oil, 10-15 parts of dichlorocresol, 10-15 parts of clove extract, 1-4 parts of citric acid, 5-10 parts of coconut oil, 5-10 parts of catechol, 1-6 parts of plant essential oil, 1-5 parts of rhizoma smilacis glabrae, 4-10 parts of Camomile liquid extract, 10-15 parts of Chinese violet, 1-5 parts of seaweed polysaccharide and 4-8 parts of tea tree oil. The environment-friendly disinfectant has the advantages of simple production process and environment-friendly non-pollution production process, and the prepared environment-friendly disinfectant can effectively remove bacteria on the surface of skin, also can form a layer of protective film to protect the skin, and can protect the skin for a long time.

Owner:MAANSHAN NIUZE TECH SERVICE

Dustproof coating for car fender and preparation method of dustproof coating

InactiveCN106280945AImprove anti-stick performanceTake advantage ofPolyurea/polyurethane coatingsPolyester coatingsMethyl carbonateCorrosion

The invention discloses a dustproof coating for a car fender. The dustproof coating is prepared from the following raw materials: polyurethane resin, pure acrylic emulsion, organic silicon modified polyester resin, ethylene resin, sodium carbonate, a leveling agent, a catalyst, a synergist, mica powder, titanium dioxide, methyl isobutyl ketone, dimethyl carbonate, deionized water and rosin modified resin. The preparation method successively comprises the following steps: (1) uniformly stirring the raw materials; (2) preparing a mixed solution; (3) preparing a coating mixed solution; and (4) grinding the coating mixed solution, and filtering to obtain a finished product. The product is excellent in performance and good in dustproof performance; a coating layer has a flat, exquisite and smooth surface and good gloss retention, both the tensile strength and elongation rate at break are better than those of an ordinary coating, and the application requirements of the car fender on the corrosion resistance and weather resistance of the coating of a box body can be met; and the preparation method is simple, relatively low in cost and suitable for industrialized mass production.

Owner:安徽班合拍卖服务有限公司

Leather product edge repairing formula

InactiveCN106987662AEfficient repairRestore aestheticsPolishing compositionsLeather surface finishingEmulsionManufacturing technology

The invention discloses a leather product edge repairing formula. Each part of the leather product edge repairing formula includes, by mass, 55 kg-65 kg of an acrylic emulsion, 0.3 kg-0.7 kg of an P95 auxiliary, 0.3 kg-0.7 kg of an antifoaming agent, 0.7 kg-1.3 kg of a functional auxiliary, 27 kg-33 kg of inorganic padding and 6 kg to 10 kg of pigment paste. By means of the leather product edge repairing formula, the manufacturing technology is simple, the manufacturing process is environment-friendly and free of pollution, a prepared leather product edge repairing agent can be used for effectively repairing a leather product edge, and the attractiveness of a leather product can be recovered; and in addition, the acrylic emulsion is added in the formula and is free of toxins and irritation, no harm is caused to the human body, the environment friendliness requirement is met, in addition, good glossiness and transparency are achieved, and the glossiness and attractiveness of the leather product can be improved.

Owner:浙江威利达新材料有限公司

Anti-aging paint for car storage box and preparing method thereof

InactiveCN106221451AImprove aging resistanceFlat surfaceAnti-corrosive paintsEpoxy resin coatingsWeather resistanceSilicone

The invention discloses anti-aging paint for a car storage box. The anti-aging paint is prepared from hydroxy acrylic resin, silicone acrylic emulsion, alkyd resin, epoxy resin, isocyanate, dispersant, catalyst, thickener, calcium carbonate, ferrotitanium powder, propylene glycol monomethyl ether, cyclohexane, deionized water and pentaerythritol. A method for preparing the anti-aging paint sequentially comprises the steps of 1, evenly stirring corresponding raw materials; 2, preparing a mixed solution; 3, preparing paint mixed liquid; 4, grinding the paint mixed liquid, and conducting filtration to obtain the finished product. An obtained coating has a flat, fine and smooth surface and high gloss retention property, tensile strength and elongation at break are both higher than those of ordinary paint, and then using requirements of the car storage box for corrosion resistance and weather resistance of box coating can be met; the preparing method is simple and low in cost and suitable for industrial bulk production.

Owner:安徽班合拍卖服务有限公司

Anti-acid and anti-alkali insulating material and production process thereof

InactiveCN105885137AThe production process is simpleExcellent acid and alkali resistancePhosphateTrimethylolpropane

The invention discloses anti-acid and anti-alkali insulating material and production process thereof. The insulating material comprises, by weight, 30-40 parts of nitrile rubber, 18-25 parts of epoxy modified furan resin, 20-40 parts of alkali-resistant glass fiber, 15-25 parts of polyphenylene sulfide fiber, 10-30 parts of basalt fiber, 10-20 parts of phthalocyanine compound, 10-25 parts of fine nano silicon powder, 8-15 parts of polyvinyl chloride, 8-12 parts of fine silicon carbide powder, 15-25 parts of nano modified epoxy resin, 8-17 parts of active calcium silicate, 8-12 parts of trimethylolpropane and 10-15 parts of zinc dialkyl dithio phosphate. The anti-acid and anti-alkali insulating material has the advantages that the preparation process of the anti-acid and anti-alkali insulating material is simple, environmentally friendly and free of pollution, the prepared insulating material is excellent in acid resistance, alkali resistance and flame retardance, and products prepared by the insulating material is suitable for being used in harsh environments and long in service life.

Owner:李文军

Antistatic composite calcium carbonate and preparation method thereof

InactiveCN106280558AImprove antistatic performanceTake advantage ofOther chemical processesPigment treatment with macromolecular organic compoundsWaxGlycol ethers

The invention discloses antistatic composite calcium carbonate and a preparation method thereof. The antistatic composite calcium carbonate is prepared from the following raw materials: calcium carbonate, modified polyurethane resin, chlorinated rubber resin, wax powder, barium sulfate, acrylate, cyclohexane, glycol ether, butanol, a modifying agent and right amount of water. The preparation method of the antistatic composite calcium carbonate comprises the following steps: (1) preparing a premix for later use; (2) preparing mixed liquid; (3) preparing the modifying agent; (4) mixing the premix, the mixed liquid and the modifying agent, evenly stirring, grinding, drying and crushing to obtain superfine powder. By combining the calcium carbonate with the materials such as the barium sulfate, the modified polyurethane resin, the chlorinated rubber resin and the acrylate which have better comprehensive performance, the production technology is improved; the antistatic property of a composition is effectively improved by adopting the modifying agent and the like; the antistatic composite calcium carbonate is simple in production technology, short in production cycle, stable in quality, low in production cost and higher in application value.

Owner:中玺新材料(安徽)有限公司

Heat-insulation paint used for automobile containing box and preparation method thereof

InactiveCN106010052AImprove insulation effectSatisfy anti-corrosionCellulose coatingsCelluloseMethyl carbonate

The invention discloses a heat-insulation paint used for an automobile containing box. The heat-insulation paint comprises the following raw materials: hydroxy acrylic resin, a pure acrylic emulsion, cellulose resin, ethene resin, alumina, a leveling agent, a catalyst, a thickening agent, powdered steatile, silica, methyl isobutyl ketone, dimethyl carbonate, deionized water and pentaerythritol. The preparation method comprises the following steps: 1) uniformly stirring the corresponding raw materials; 2) preparing a mixing solution; 3) preparing paint mixed liquor; and 4) grinding the paint mixed liquor, filtering the paint mixed liquor to obtain the finished product. The product has excellent performance, and has advantages of good high temperature resistance, flat and fine coating surface, and good light retention, tensile strength and breaking elongation are better than that of the common paint, the usage requirements of anticorrosion and weatherability of the automobile containing box on coating can be satisfied; and the preparation method has the advantages of simple process and low cost, and is adapted to industrial batch production.

Owner:安徽班合拍卖服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com