Environment-friendly power cable insulating material

A technology of power cables and insulating materials, which is applied in the field of environment-friendly power cable insulation materials, can solve the problems of casualties, property, losses, fires, etc., and achieve the effects of prolonging service life, increasing elasticity, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

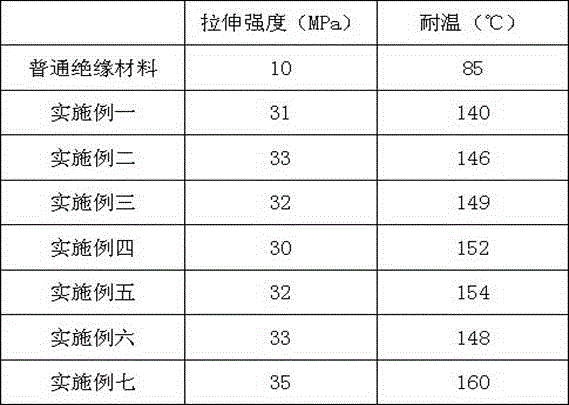

Examples

Embodiment 1

[0016] The proportion of ingredients used is: 15 parts of nano-scale silicon dioxide, 15 parts of polyolefin, 10 parts of silicone crosslinking agent, 10 parts of oil retardant, 2 parts of plasticizer, 25 parts of phenolic resin, and 20 parts of polypropylene reinforcing fiber 15 parts of paraffin oil, 2 parts of chitosan, 5 parts of polyacrylate, 10 parts of toughening agent, 5 parts of silicon micropowder, 20 parts of nano zinc oxide and 15 parts of polybutylene terephthalate.

[0017] Preparation technique of the present invention comprises the following steps:

[0018] A. Put nano-scale silica, polyolefin, silicone crosslinking agent, retardant oil, and plasticizer into the mixer for high and low speed mixing. The stirring sequence is high speed stirring for 10 minutes, low speed stirring for 10 minutes, and high speed stirring for 5 minutes. Then stir at a low speed for 5 minutes to obtain the A mixture;

[0019] B. Add phenolic resin, polypropylene reinforcing fiber, pa...

Embodiment 2

[0024] The proportion of ingredients used is: 16 parts of nano-scale silicon dioxide, 16 parts of polyolefin, 11 parts of silicone crosslinking agent, 11 parts of oil retardant, 3 parts of plasticizer, 26 parts of phenolic resin, and 21 parts of polypropylene reinforcing fiber 16 parts of paraffin oil, 3 parts of chitosan, 6 parts of polyacrylate, 11 parts of toughening agent, 6 parts of silicon micropowder, 21 parts of nano zinc oxide and 16 parts of polybutylene terephthalate.

[0025] Preparation technique of the present invention comprises the following steps:

[0026] A. Put nano-scale silica, polyolefin, silicone crosslinking agent, retardant oil, and plasticizer into the mixer for high and low speed mixing. The stirring sequence is high speed stirring for 10 minutes, low speed stirring for 10 minutes, and high speed stirring for 5 minutes. Then stir at a low speed for 5 minutes to obtain the A mixture;

[0027] B. Add phenolic resin, polypropylene reinforcing fiber, pa...

Embodiment 3

[0032] The proportion of ingredients used is: 17 parts of nano-scale silicon dioxide, 17 parts of polyolefin, 13 parts of silicone crosslinking agent, 12 parts of oil retardant, 4 parts of plasticizer, 27 parts of phenolic resin, and 22 parts of polypropylene reinforcing fiber 17 parts, 17 parts of paraffin oil, 4 parts of chitosan, 7 parts of polyacrylate, 13 parts of toughening agent, 7 parts of silicon micropowder, 23 parts of nano zinc oxide and 17 parts of polybutylene terephthalate.

[0033] Preparation technique of the present invention comprises the following steps:

[0034] A. Put nano-scale silica, polyolefin, silicone crosslinking agent, retardant oil, and plasticizer into the mixer for high and low speed mixing. The stirring sequence is high speed stirring for 10 minutes, low speed stirring for 10 minutes, and high speed stirring for 5 minutes. Then stir at a low speed for 5 minutes to obtain the A mixture;

[0035] B. Add phenolic resin, polypropylene reinforcing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com