Polymer cement waterproof slurry and preparation method thereof

A waterproof slurry and polymer technology, applied in the field of waterproof materials, can solve the problems of decreased bond strength, mechanical properties of polymer cement waterproof slurry, etc. The effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

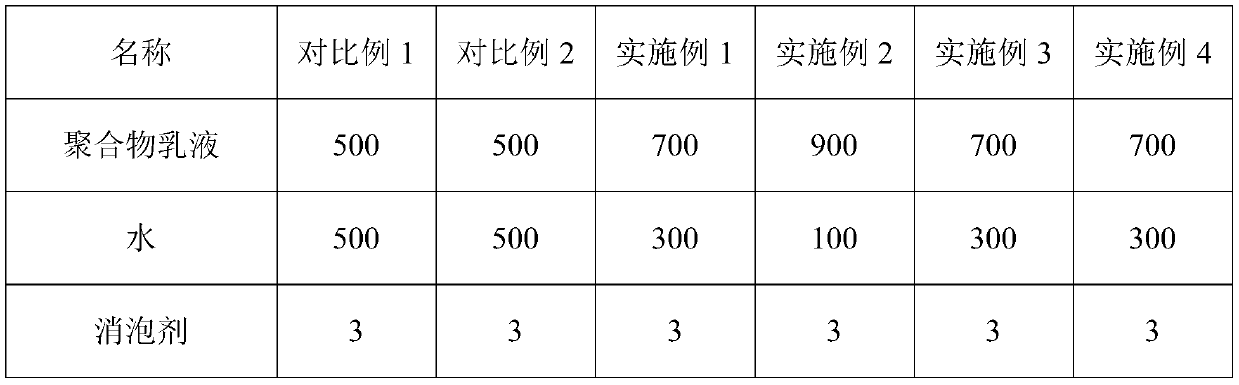

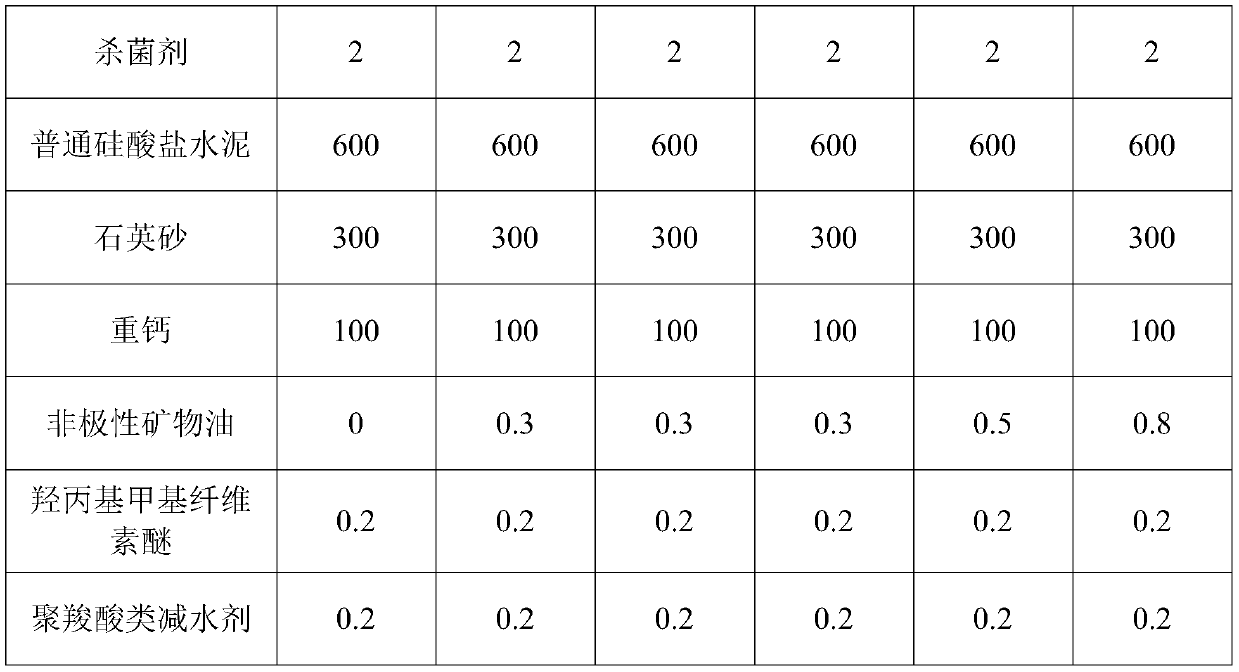

Examples

preparation example Construction

[0041] In each embodiment of the present invention, the preparation method of polymer cement waterproof slurry comprises:

[0042] Prepare raw materials according to the liquid material formula, add water into the liquid material mixing tank, turn on the disperser of the mixing tank, keep the speed at 1000 rpm, and add the polymer emulsion, defoamer, and bactericide into the liquid material mixing tank in sequence , keep the rotating speed at 1000 rpm, and stir for 15 minutes to obtain the liquid material;

[0043] Prepare raw materials according to the powder formula, turn on the gravity-free powder mixer, keep the speed at 600 rpm, add cement, sand, and fillers to the powder mixing tank, and then add cellulose ether and polycarboxylate superplasticizer to the Turn on the agitation in a gravity-free mixing tank, add non-polar mineral oil in a spray mode, and stir for 15 minutes to obtain the powder.

[0044] Before carrying out relevant tests, the liquid material and the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com