Method for synthesizing benzofuranone by taking o-chlorotoluene as raw material

A technology of benzofuranone and o-chlorotoluene, which is applied in the field of preparation of pharmaceutical intermediates, can solve the problems of harsh synthesis conditions, increased environmental pollution pressure, harsh conditions, etc., achieve high product yield and purity, and solve the problems of high raw material prices, high The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

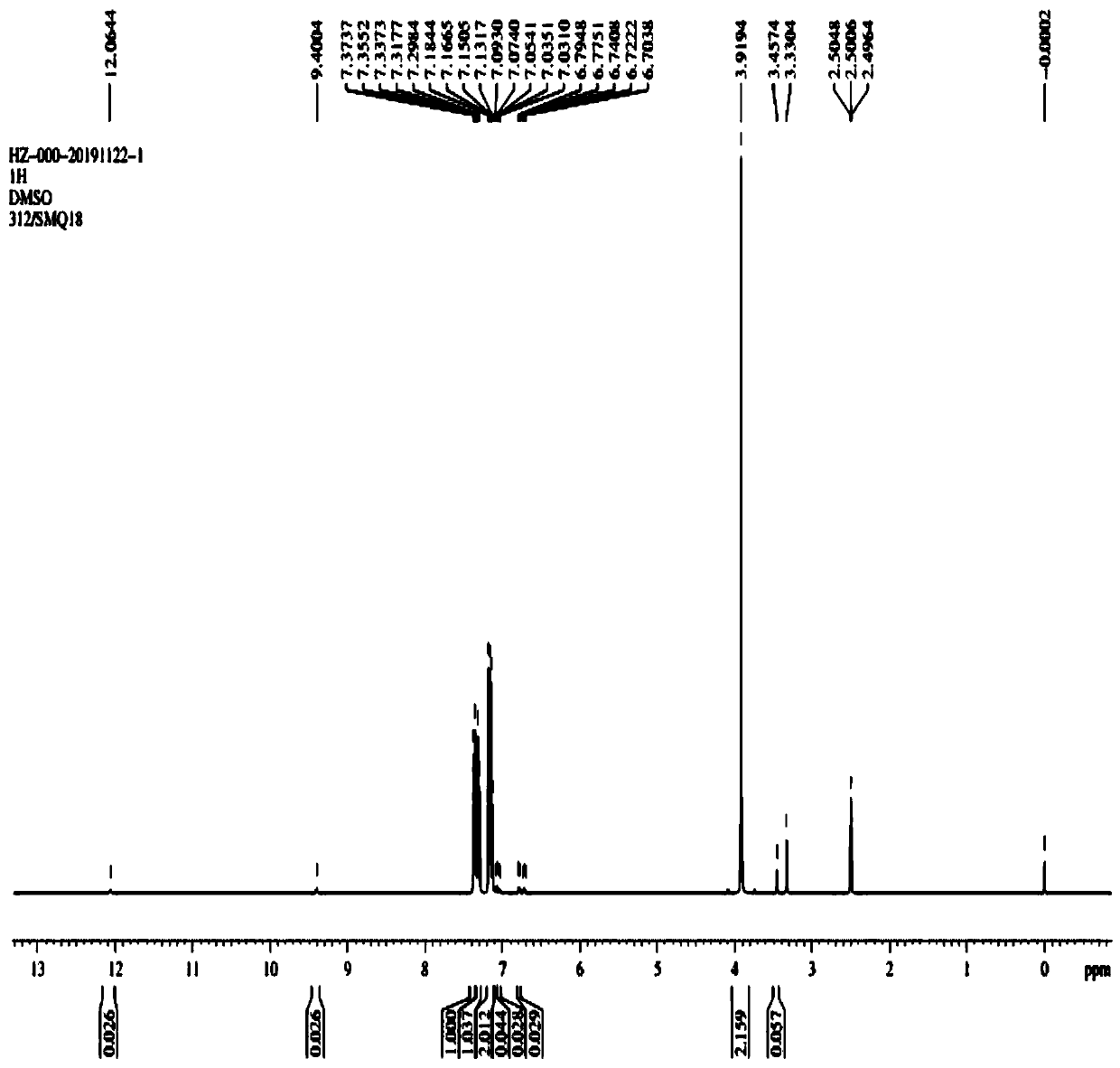

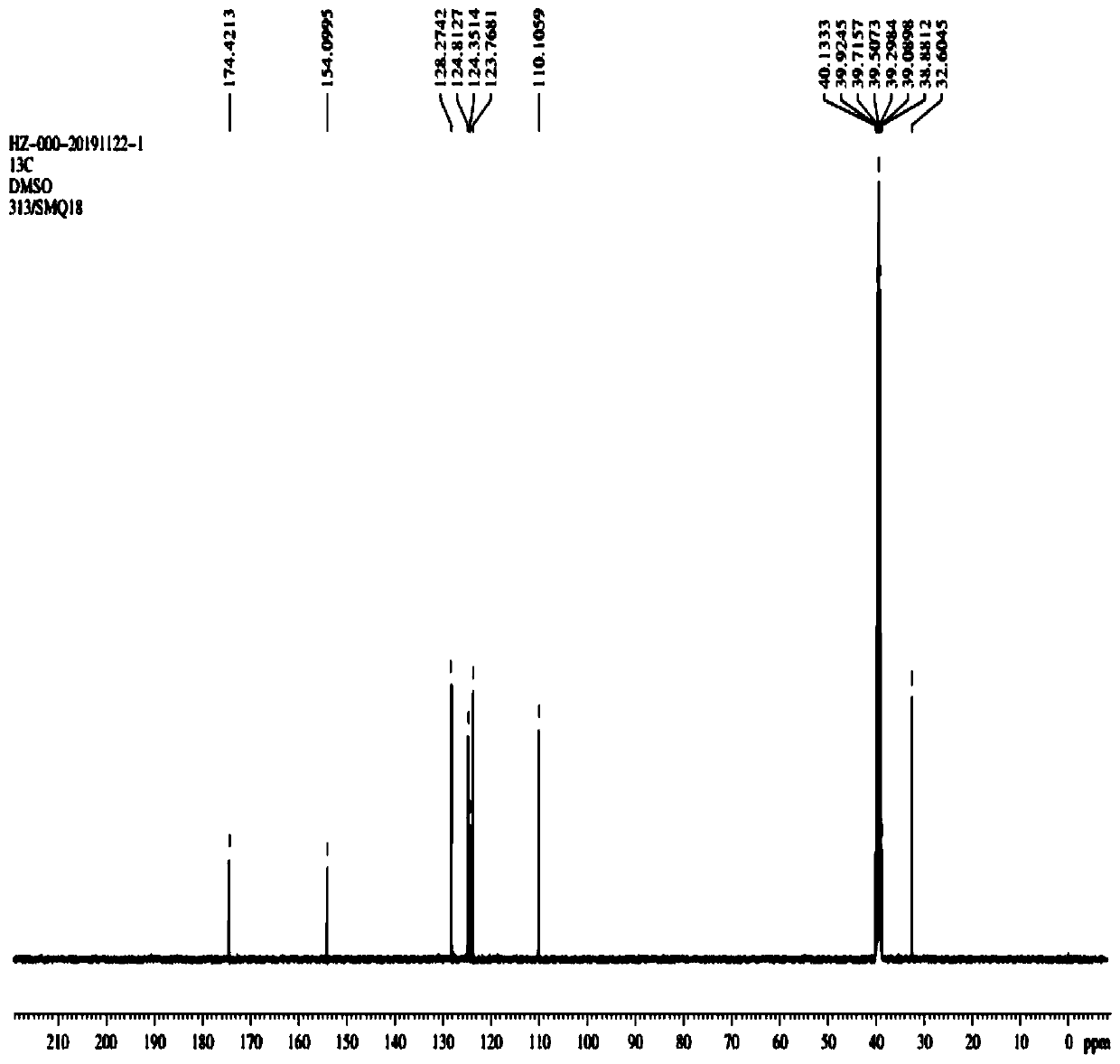

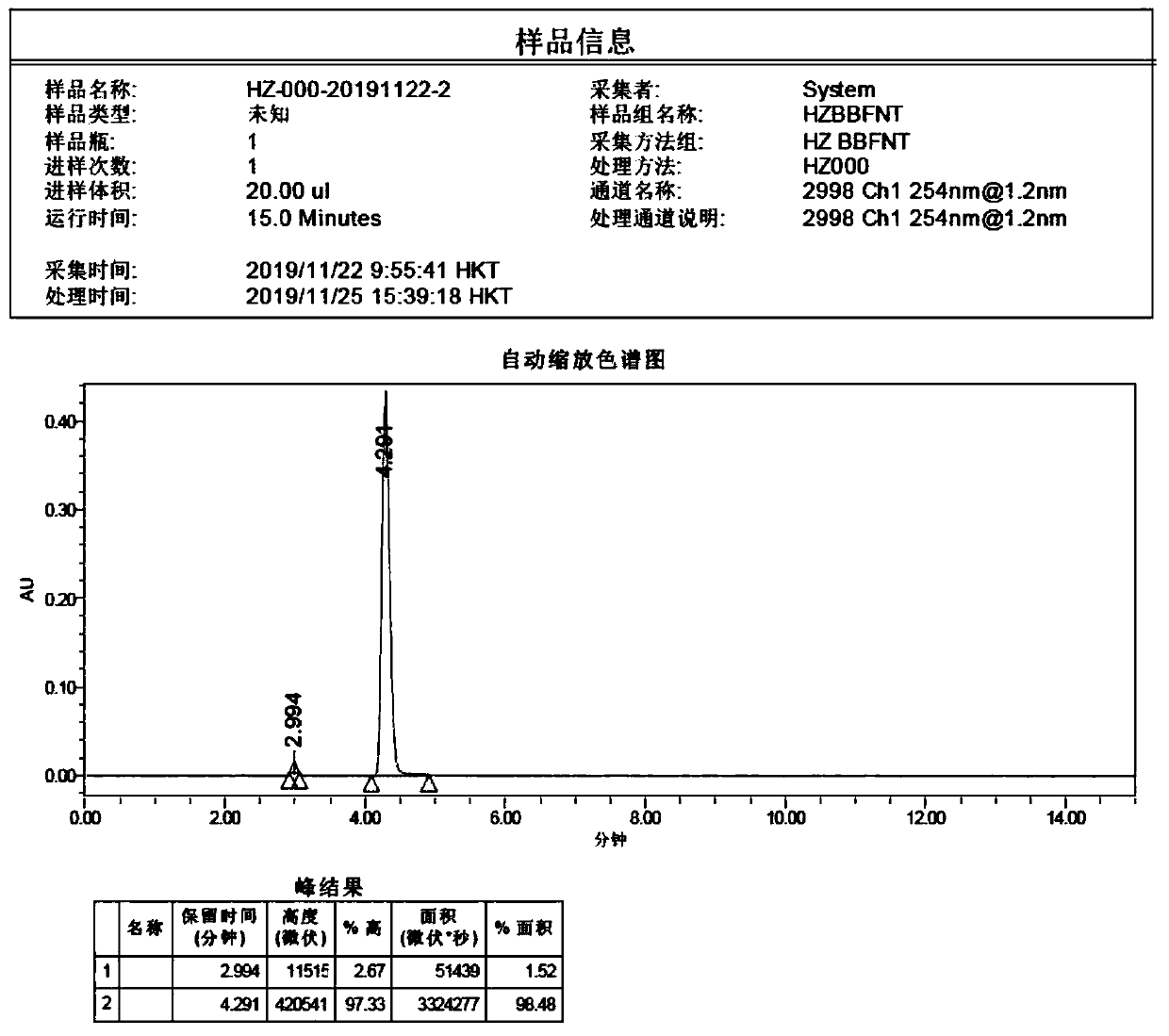

Image

Examples

Embodiment 1

[0045] A kind of method taking ortho-chlorotoluene as raw material synthetic benzofuranone, its synthetic route is as follows:

[0046]

[0047] Specifically include the following steps:

[0048] (1), 12.6g (100mmol) of o-chlorotoluene, 1.84g (40mmol) of ethanol, 5.84g (40mmol) of tert-butyl peroxyether, Pd(Xantphos)Cl 2Add 15.2mg into the reaction kettle, feed carbon monoxide to 10atm, raise the temperature to 80°C, stir and react for 24 hours, maintain the carbon monoxide pressure at 10atm during the reaction, cool to room temperature after the reaction, discharge carbon monoxide, wash with sodium bisulfite aqueous solution, and dry , the raw material is recovered by distillation, and the organic phase after distillation is obtained for subsequent use;

[0049] (2), add 20mL of 6mol / L sodium hydroxide aqueous solution to the organic phase after the distillation that step (1) obtains, heat to 100 ℃ and stir reaction 2h, after reaction finishes, cool to room temperature, a...

Embodiment 2

[0052] A kind of method taking ortho-chlorotoluene as raw material synthetic benzofuranone, its synthetic route is as follows:

[0053]

[0054] Specifically include the following steps:

[0055] (1), 12.6g (100mmol) of o-chlorotoluene, 1.84g (40mmol) of ethanol, 5.84g (40mmol) of tert-butyl peroxyether, copper fluoride (0.6mg), and Xantphos (2.9mg) were added to the reaction kettle , feed carbon monoxide to 50atm, raise the temperature to 120°C, stir and react for 16 hours, maintain the carbon monoxide pressure at 50atm during the reaction, cool to room temperature after the reaction, discharge carbon monoxide, wash with sodium bisulfite aqueous solution, dry, and distill to recover the raw materials to obtain distilled The last organic phase is standby;

[0056] (2), add 20mL of 6mol / L sodium hydroxide aqueous solution to the organic phase after the distillation that step (1) obtains, heat to 170 ℃ and stir reaction 2h, cool to room temperature after reaction finishes, a...

Embodiment 3

[0059] A kind of method taking ortho-chlorotoluene as raw material synthetic benzofuranone, its synthetic route is as follows:

[0060]

[0061] Specifically include the following steps:

[0062] (1), 12.6 g (100 mmol) of o-chlorotoluene, 1.84 g (40 mmol) of ethanol, 5.84 g (40 mmol) of tert-butyl peroxide, ruthenium trichloride (1.1 mg), and Xantphos (2.9 mg) were added to the reaction kettle, Introduce carbon monoxide to 50 atm, raise the temperature to 150°C, stir and react for 10 hours, maintain the pressure of carbon monoxide at 50 atm during the reaction, cool to room temperature after the reaction, discharge carbon monoxide, wash with sodium bisulfite aqueous solution, dry, and distill to recover raw materials to obtain distilled The organic phase is ready for use;

[0063] (2), add 20mL of 6mol / L aqueous sodium hydroxide solution to the organic phase obtained in step (1), heat to 200°C and stir for 2h, cool to room temperature after the reaction, and adjust the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com