Hollow corn stalk brick building block and preparation method thereof

A technology of corn stalks and hollow bricks, which is applied in building components, sustainable waste treatment, solid waste management, etc., can solve the problems of poor thermal insulation and sound insulation of non-load-bearing walls, different life spans of load-bearing walls and insulation layers, etc., and improve the compressive performance Harmonious water performance, high environmental protection and energy saving value, easy structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

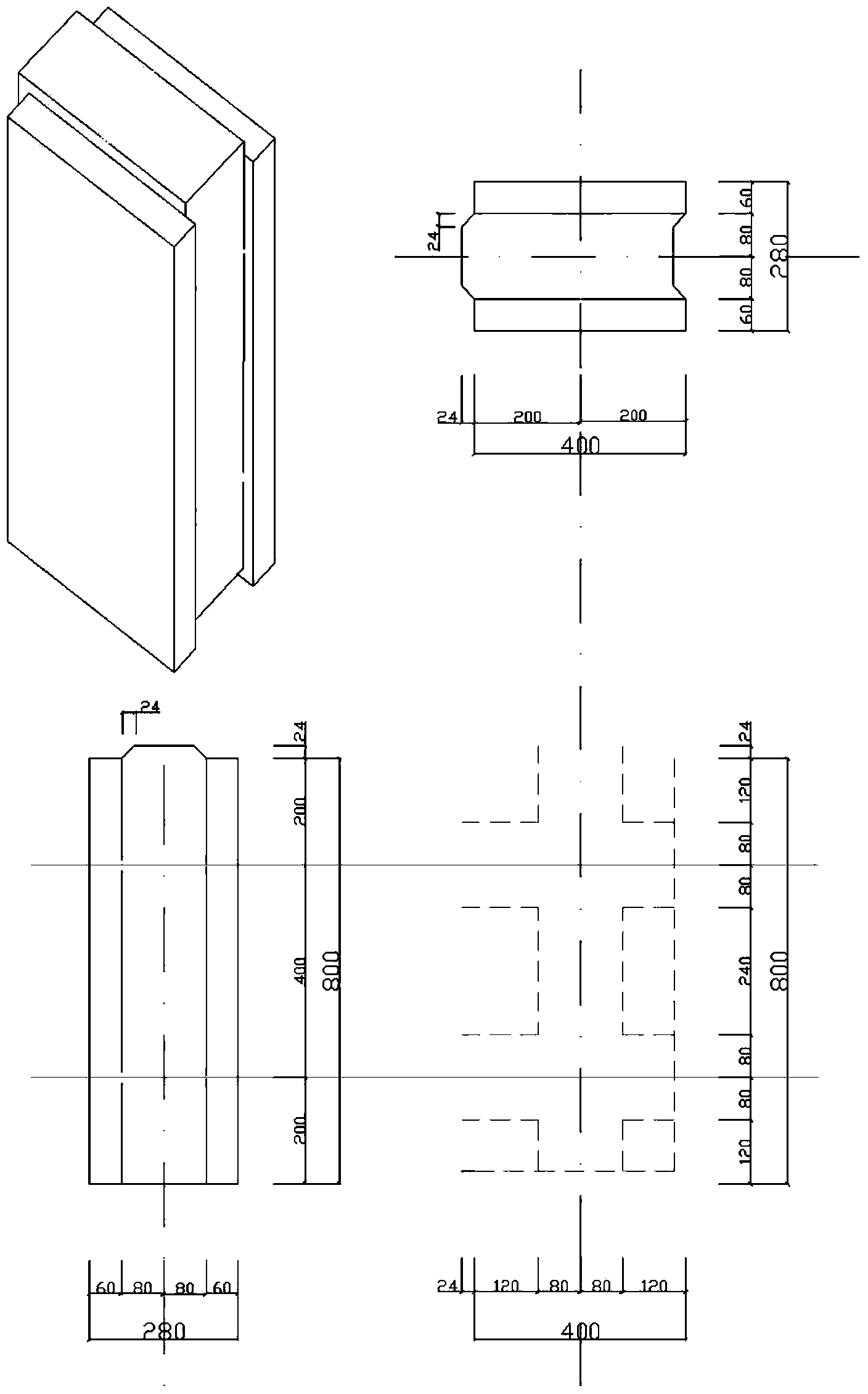

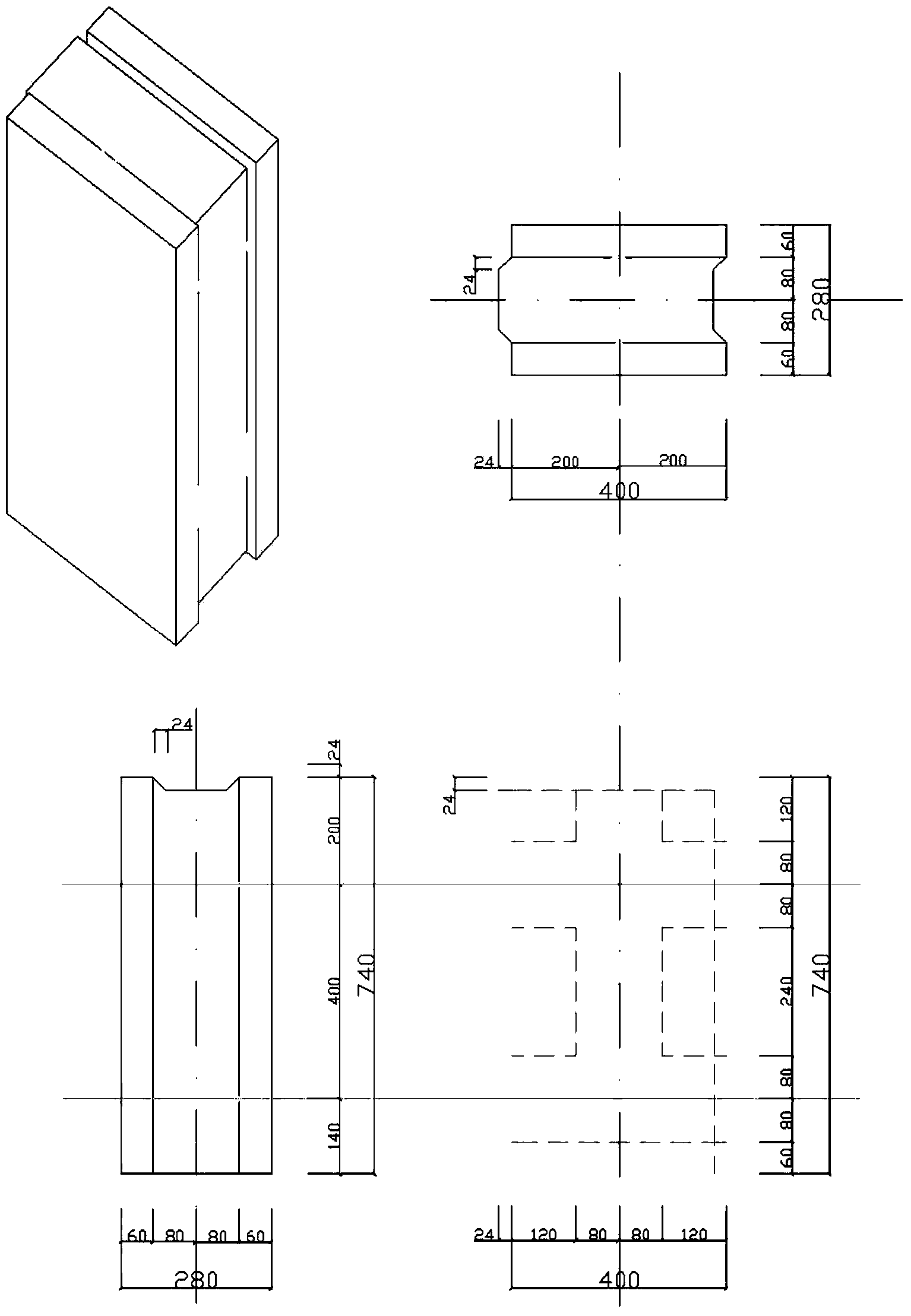

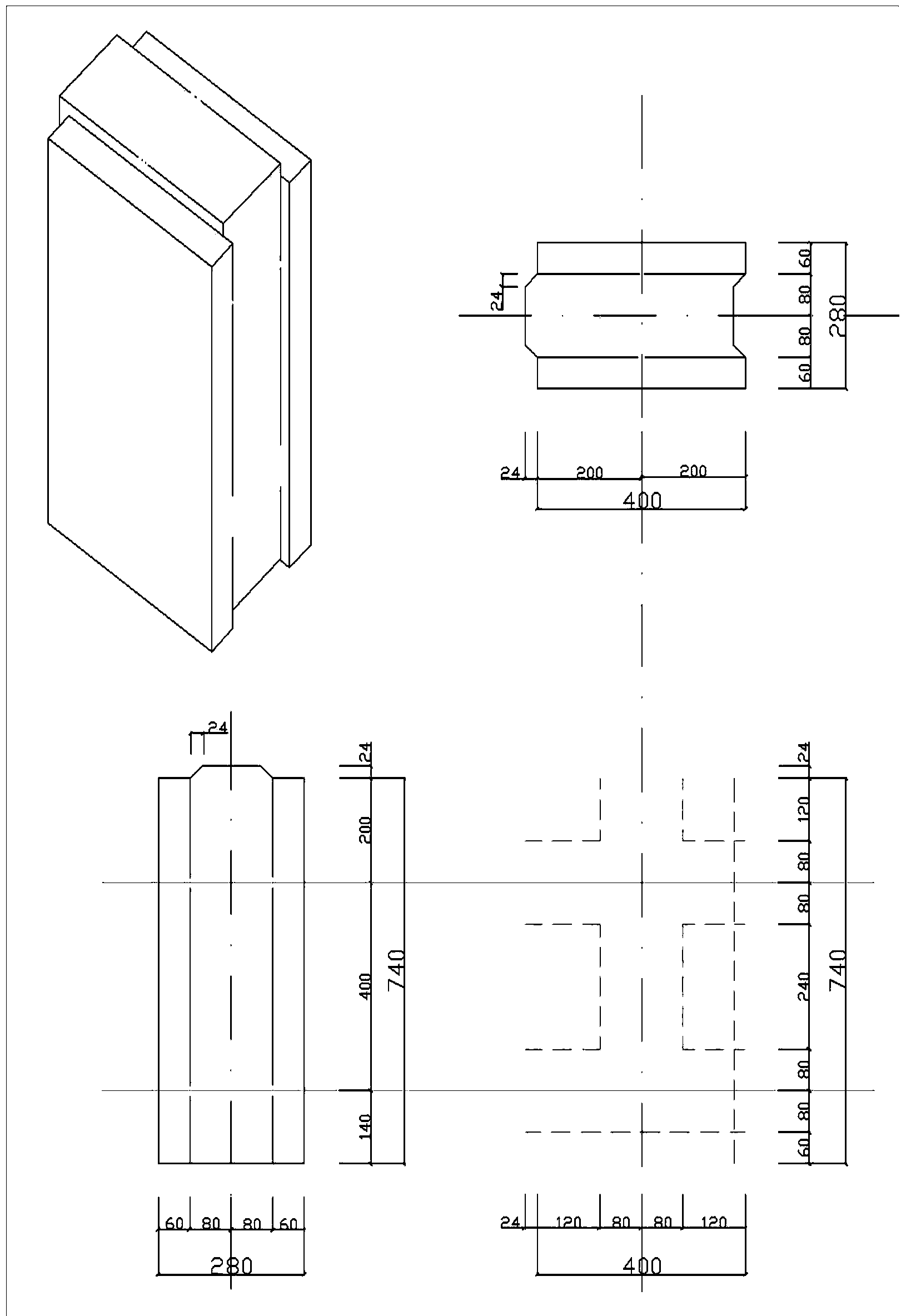

Image

Examples

preparation example Construction

[0073] The present invention has no special limitation on the preparation method of the corn stalk hollow brick block, and the technical scheme for block preparation well-known to those skilled in the art can be adopted.

[0074] The invention provides a method for preparing corn stalk hollow brick blocks, comprising the following steps:

[0075] Mixing and reacting corn stalks and modifiers to obtain modified corn stalks;

[0076] mixing the modified corn stalks with cement, quick-drying agent and water to obtain block materials;

[0077] The block material is molded, pressed and shaped and demolded to obtain a corn stalk hollow brick block.

[0078] In the present invention, the first choice is the mixed reaction of corn stalks and modifiers to obtain modified corn stalks. The present invention uses the modifying agent described in the above technical solution to modify corn stalks to promote the interaction between corn stalks and cement. The present invention has no spe...

Embodiment 1

[0128] Process 71.25 kg of corn stalks to obtain corn stalk granules with a length of 6 mm to 12 mm and a width of 3 mm to 6 mm, and combine the obtained corn stalk granules with 3.75 kg of modifiers (specify the types of modifiers), 25 kg of Cement (please provide the source of the cement), 1.25kg of quick-drying agent (please provide the specific quick-drying agent and its source) and 12.5kg of water are stirred in a mixer for 5 minutes to obtain block materials;

[0129] Set the parameters of casting and pressing in the automatic casting machine according to the needs, and transport the obtained block material to the automatic casting machine through the conveying and distributing machine for casting and pressing. The pressure is 60kg, and then decompressed, the upper pressure plate rises automatically, the baffles on both sides are separated, the barrier film falls off completely after the sideways, and the bottom plate is moved to the platform, demoulding and marking, and ...

Embodiment 2

[0133] Crush 100kg of corn stalks with a moisture content of <20%, separate and grow into corn stalk particles of 6 mm to 12 mm in width and 3 mm to 6 mm in width, and the obtained corn stalk particles have a mass of 60 kg. Mix the obtained corn stalk particles with 3 kg of modifier , 16.25kg of cement, 1.8kg of quick-drying agent and 8.12kg of water were stirred in a mixer for 10 minutes to obtain block materials;

[0134] Set the parameters of casting and pressing in the automatic casting machine according to the customer's requirements, and transport the obtained block material to the automatic casting machine through the conveying and distributing machine for casting and pressing. The setting pressure is 60kg, and then the pressure is decompressed, the upper side pressure plate is automatically raised, the two side baffles are separated, the barrier film is turned over and completely falls off, the bottom plate is moved to the platform, demoulding, marking, and the masonry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com