Combined forming equipment suitable for filtered water core material

A technology for forming equipment and core materials, which is applied to other household appliances, household appliances, household components, etc., can solve the problem of affecting the assembly and use of the core material for filtering water, the length of the binding layer being easily sent and dispersing, and affecting the overall quality of the filtering water core. and other problems, to achieve the effect of combining tightness, reasonable structure configuration and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

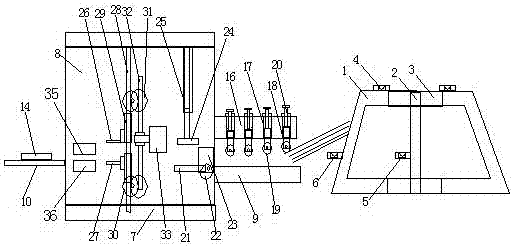

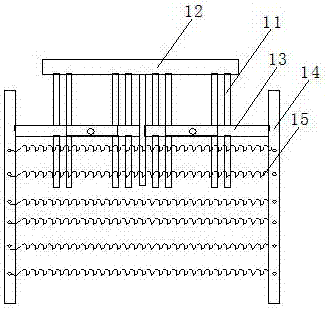

[0020] Example 1, such as figure 1 , 2 . As shown in 3, a combined molding equipment suitable for filtering water core core materials is characterized in that: it includes a material discharging structure and a core material bending and distributing device, and the described material discharging structure is a trapezoidal frame body 1. A vertical bearing rod 2 is provided at the vertical center of the frame body 1, and a moving adjustment block 3 is provided at the upper and lower ends of the bearing rod 2, and the moving adjustment block 3 is in the shape of “[”; On the upper and lower frames of the frame body, two top shaft roller placement blocks 4 are arranged on the top of the frame body 1, and a first lateral shaft roller placement block 5 is provided at the right end of the load bar 2. The hypotenuse is provided with a second lateral shaft roller placement block 6;

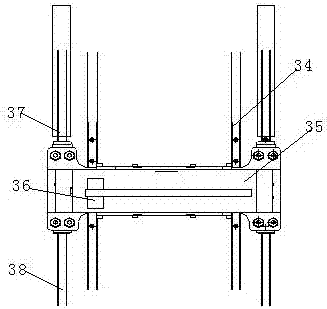

[0021] The core material bending and distributing equipment includes a workbench 7, a material process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com