Pipe, pipe manufacturing method and stretchable water pipe

A manufacturing method and technology of pipe materials, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve problems such as breakage, easy damage of inner elastic water pipes, and easy leakage of inner elastic water pipes, etc., so that it is not easy to wear and beautiful Easy to store and hold, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

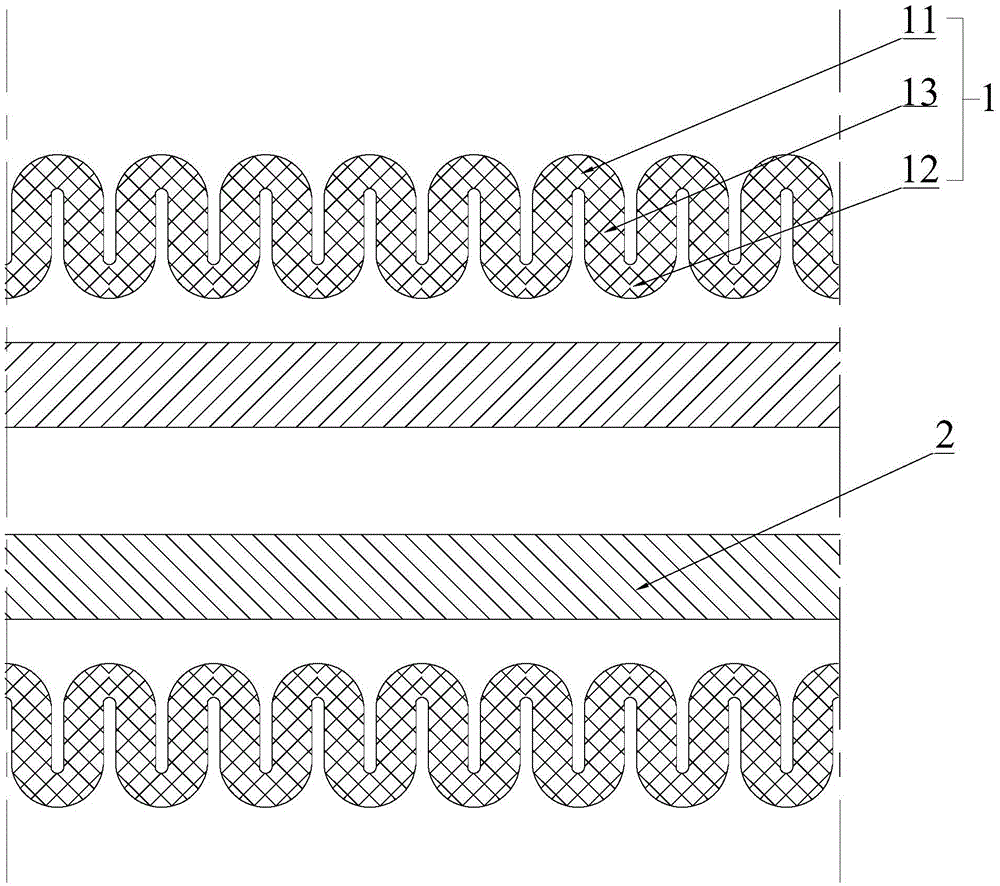

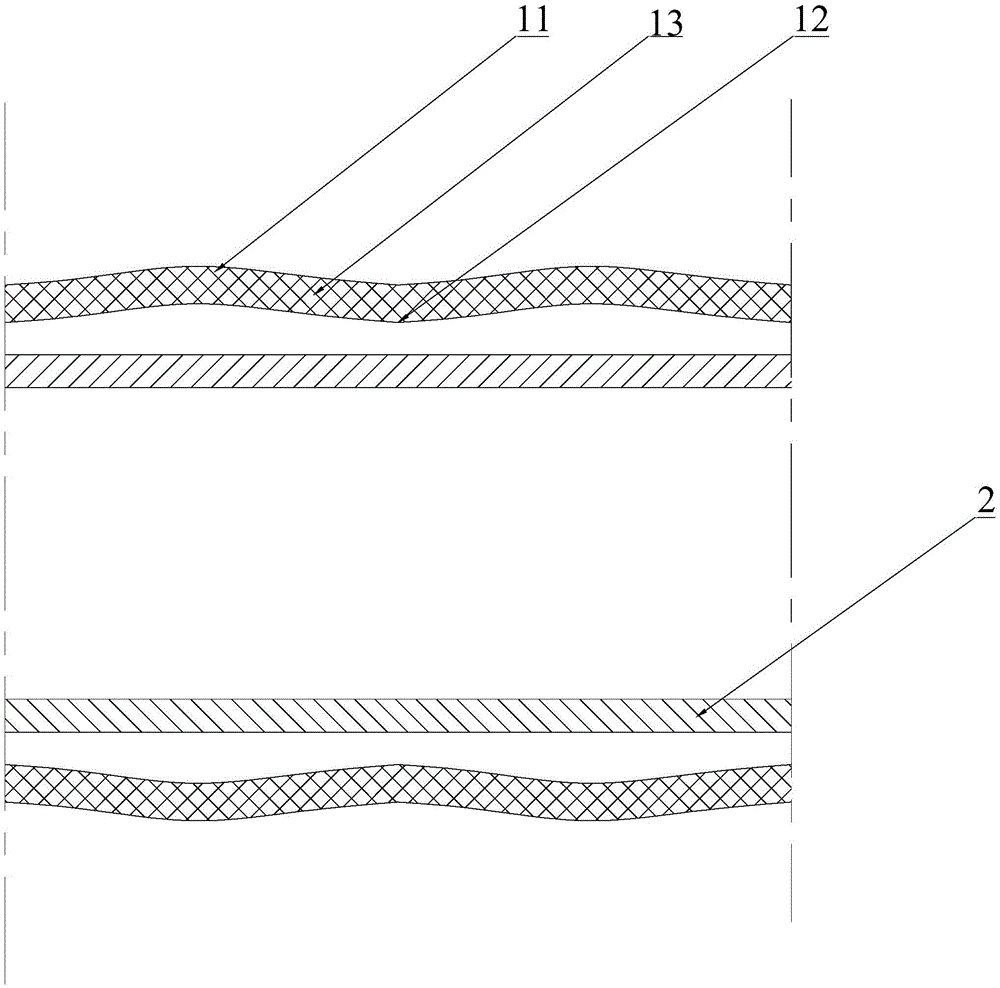

[0029] The technical solution of the present invention is to provide a pipe with the following structure, including a pipe body that is stretchable along the length direction, and a plurality of flexible convex rings extending outward from the wall of the pipe body when the pipe body is naturally contracted. In the state of natural contraction of the main body of the pipe, the pipe wall is integrally extended inward with several flexible concave rings. The flexible convex rings and flexible concave rings are arranged at intervals along the length direction of the main body of the pipe and connected by connecting sections. The outer part of the flexible convex ring The diameter is 1.5-2.5 times of the inner diameter of the flexible concave ring.

[0030]After adopting the above structure, compared with the prior art, the pipe of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com