Efficient energy-saving continuous bubbling and wrinkling oxygen bleaching dyeing machine and material conveying method thereof

A high-efficiency energy-saving, dyeing machine technology, applied in the continuous processing of textile materials, textile processing machine accessories, textile material processing, etc., to achieve the effect of reducing production costs, reducing labor, and improving grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

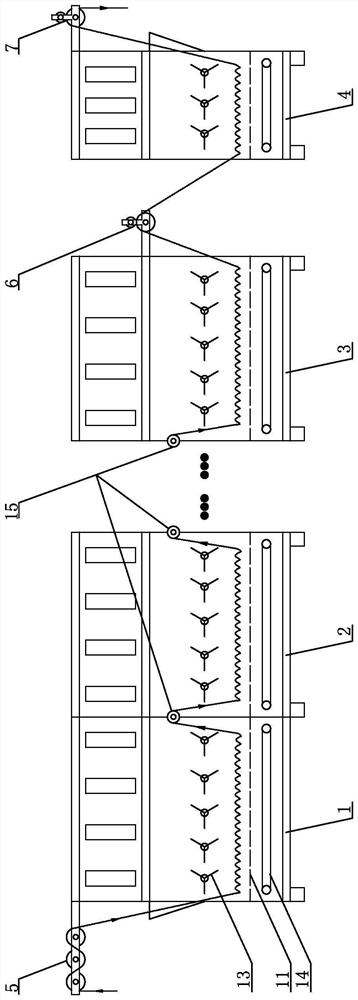

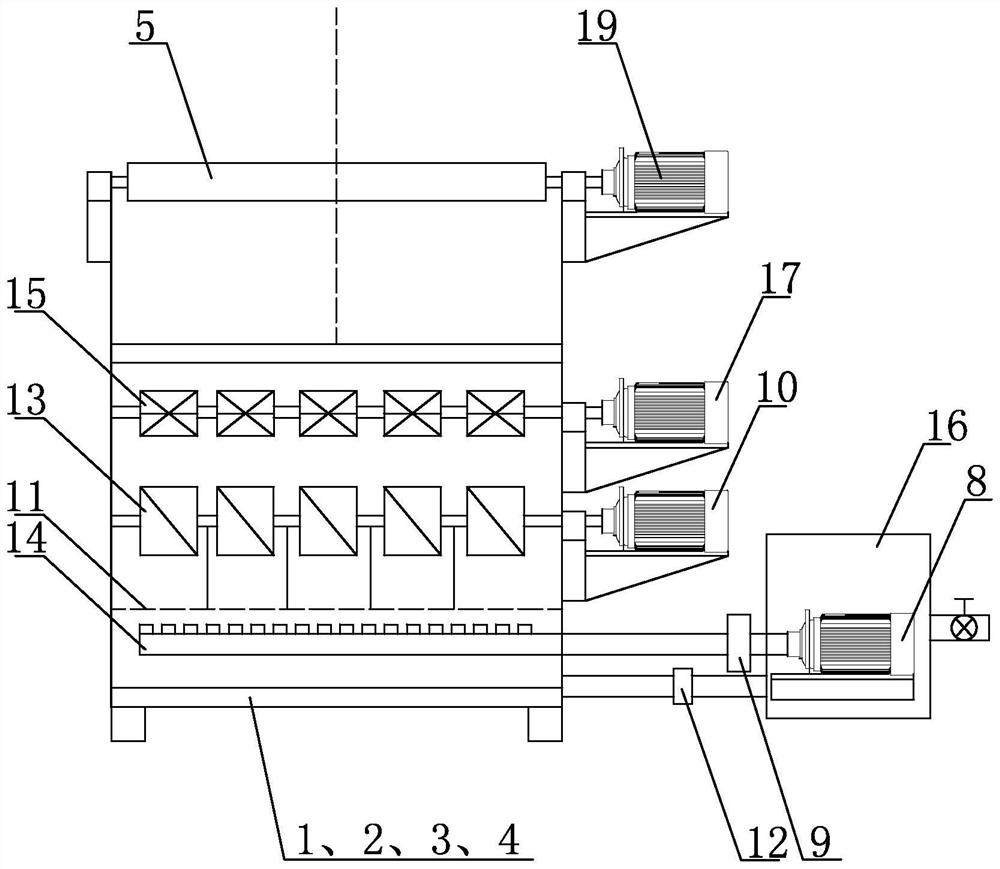

[0039] A high-efficiency energy-saving continuous bubble and cream, such as Figure 1 to 4 As shown, including the head cylindrical module 1, a plurality of intermediate cylindrical modules 2, the tail cylindrical module 3, the neutralization cylindrical module 4, the roller set drive mechanism and the auxiliary delivery system, each of the cylindrical modules is divided into several A conveying channel, and the upper portion of the conveying channel is separated between the two adjacent conveying channels, and the upper portion of the conveying channel is provided with a flip roller 13, and the lower portion is provided with auxiliary delivery. The all-in-flap 14 is connected; the feed end of the head barrel module 1 is provided with a welding roller set 5, between the head cylindrical module 1 and the intermediate barrier module 2, adjacent two intermediate cylinders. Between the module 2, there is a tubular roller set 15 between the intermediate cylindrical module 2 and the tail...

Embodiment 2

[0048] Example 1 Treatment of the textile fabric adopts linear delivery form, the advantage is that the yield is high, but for some fabrics, there may be a defect with an incomplete reaction with the auxiliary reaction, and Example 2 uses the way to convey it. Solve the above defects, as described below.

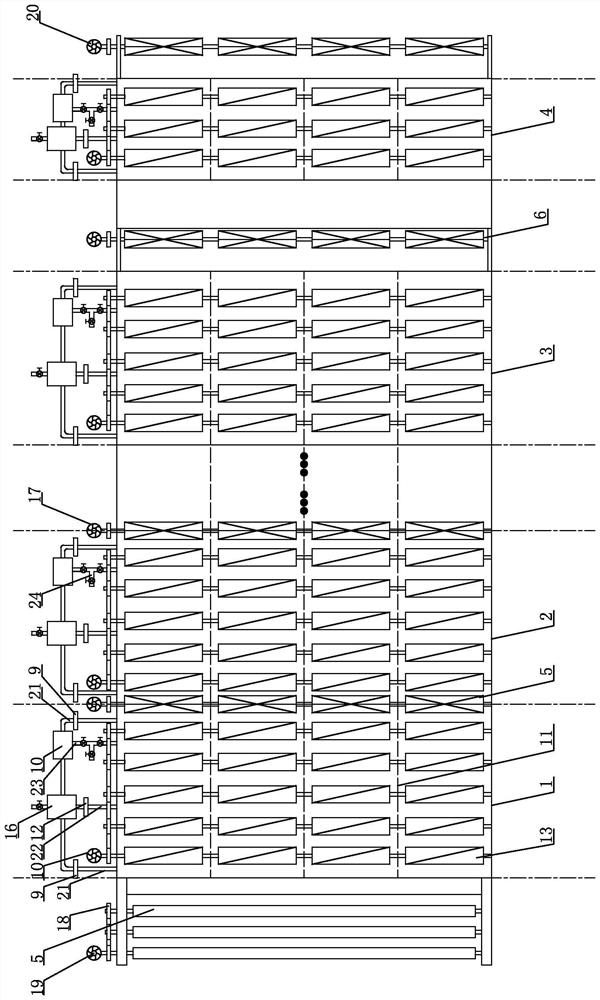

[0049] Such as Image 6 As shown, each of the cylindrical modules of the apparatus includes three conveying channels, a head cylindrical module 1, a plurality of intermediate cylindrical modules 2, and the three conveyance channels of the tail cylindrical module 3 form a station (which can be applied. Set a plurality of stations, each station is run separately, and does not affect each other), the same station is adjacent to the two conveying channels, and the adjacent two transport channels are provided with a tail end of the tail (this The cloth roller is used in the conversion of the fabric delivery direction), and the textile fabric is input from the first end of the first co...

Embodiment 3

[0051] Such as Figure 7 As shown, the present embodiment is the same as that of Example 2, and the difference is that the neutralization of the cylindrical module 4 is divided into one conveying channel, the textile fabric is output from the tail end of the tail end of the tail cylinder module. Afterward, the straight line is passed and output from the inner and the cylindrical module 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com