Metal plate bending mechanism and implementation method thereof

A technology of bending mechanism and sheet metal, which is applied in the field of sheet metal bending mechanism and its realization, can solve the problems of low precision and low bending stability, and achieve the goal of ensuring stability, high structural compactness, and uniform folds Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

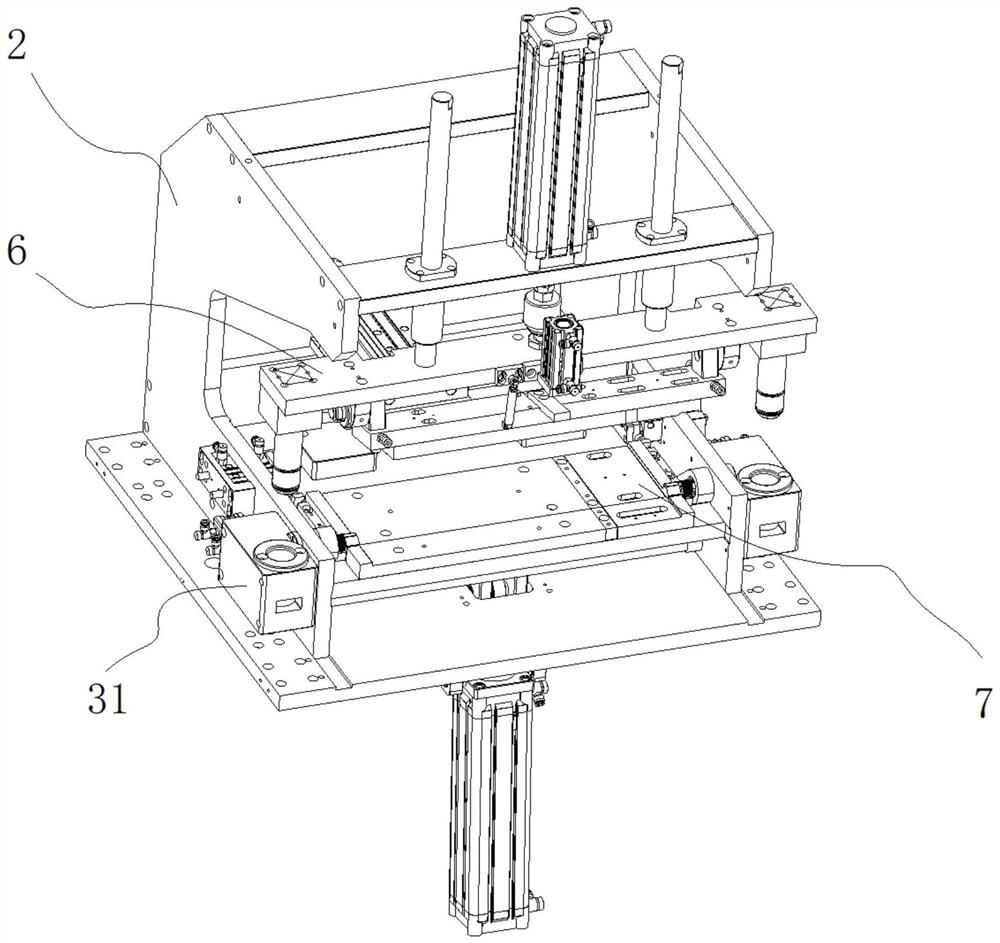

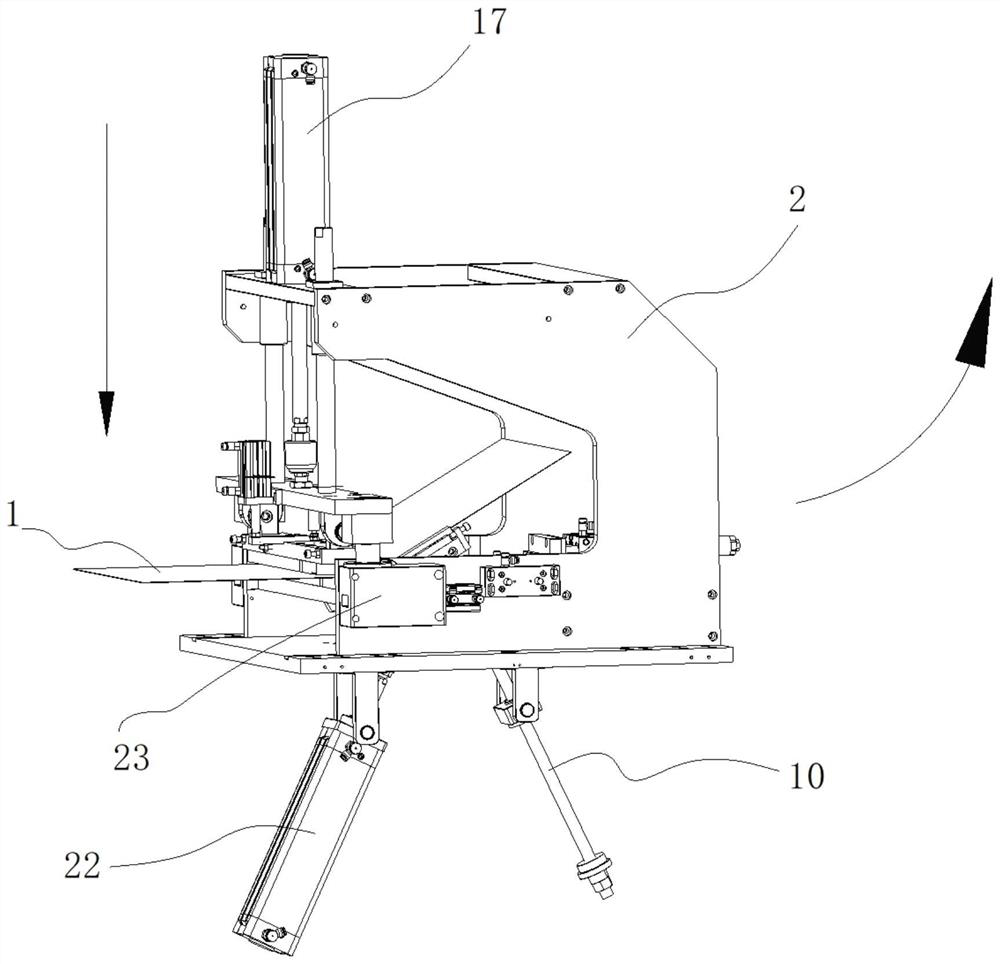

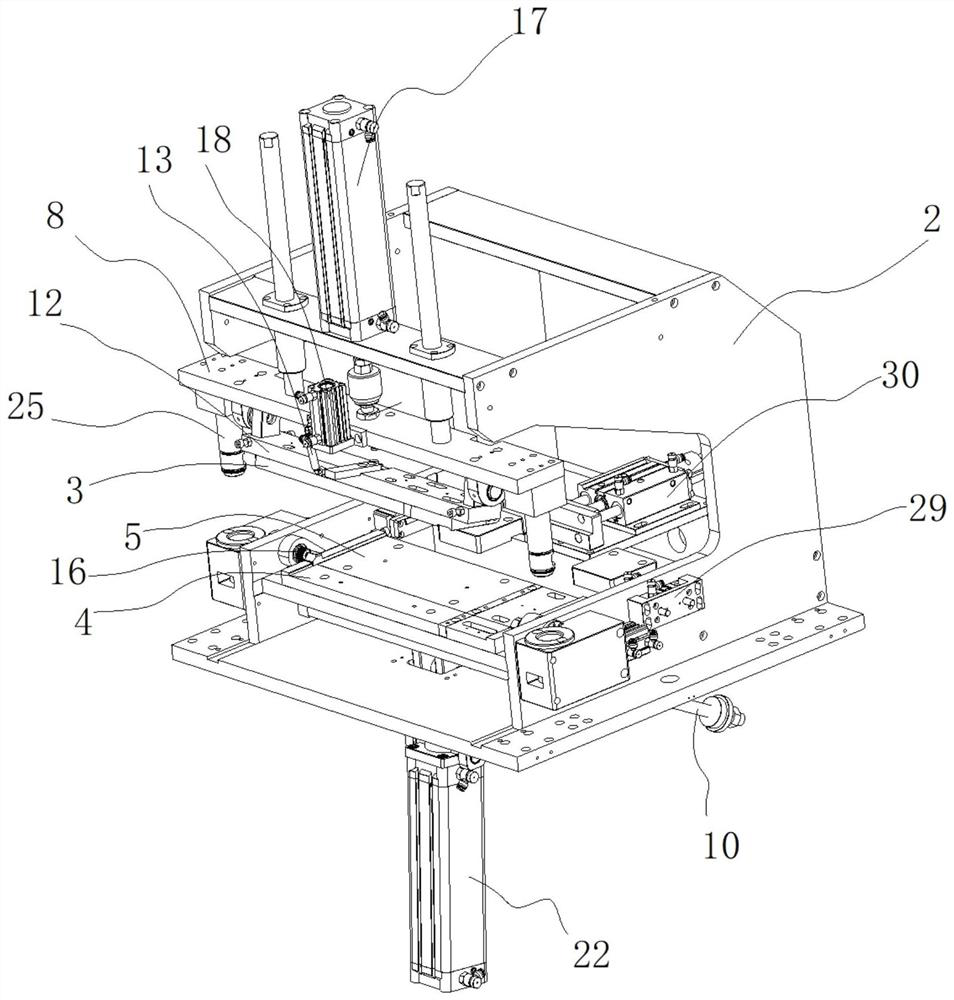

[0042] Embodiment 1: As shown in the figure, a sheet metal bending mechanism includes a sheet material 1 and an operating frame 2. The upper end of the operating frame 2 is provided with a downwardly shiftable and reversible upper mold pressing plate 3. The lower end of the operating frame 2 is provided with a lower mold fixed plate 4 and a lower mold movable plate 5, and the lower mold movable plate 5 is bent upward along the lower mold fixed plate 4, and the lower mold fixed plate 4 and the movable plate of the lower mold 5 form a bending platform;

[0043] The plate 1 is extended to the movable plate 5 of the lower mold through the fixed plate 4 of the lower mold, and the pressing plate 3 of the upper mold is displaced downward and then pressed against the plate 1, and the movable plate 5 of the lower mold is bent upward to complete the bending operation .

[0044] The upper end of the operating frame 2 is provided with a binder turning assembly 6, and the lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com