Sewing control method and system of sewing machine

A control method and control system technology, applied in the direction of sewing machine components, program-controlled sewing machines, sewing equipment, etc., can solve problems affecting sewing quality, local wrinkles, etc., and achieve high sewing quality and uniform folded folds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

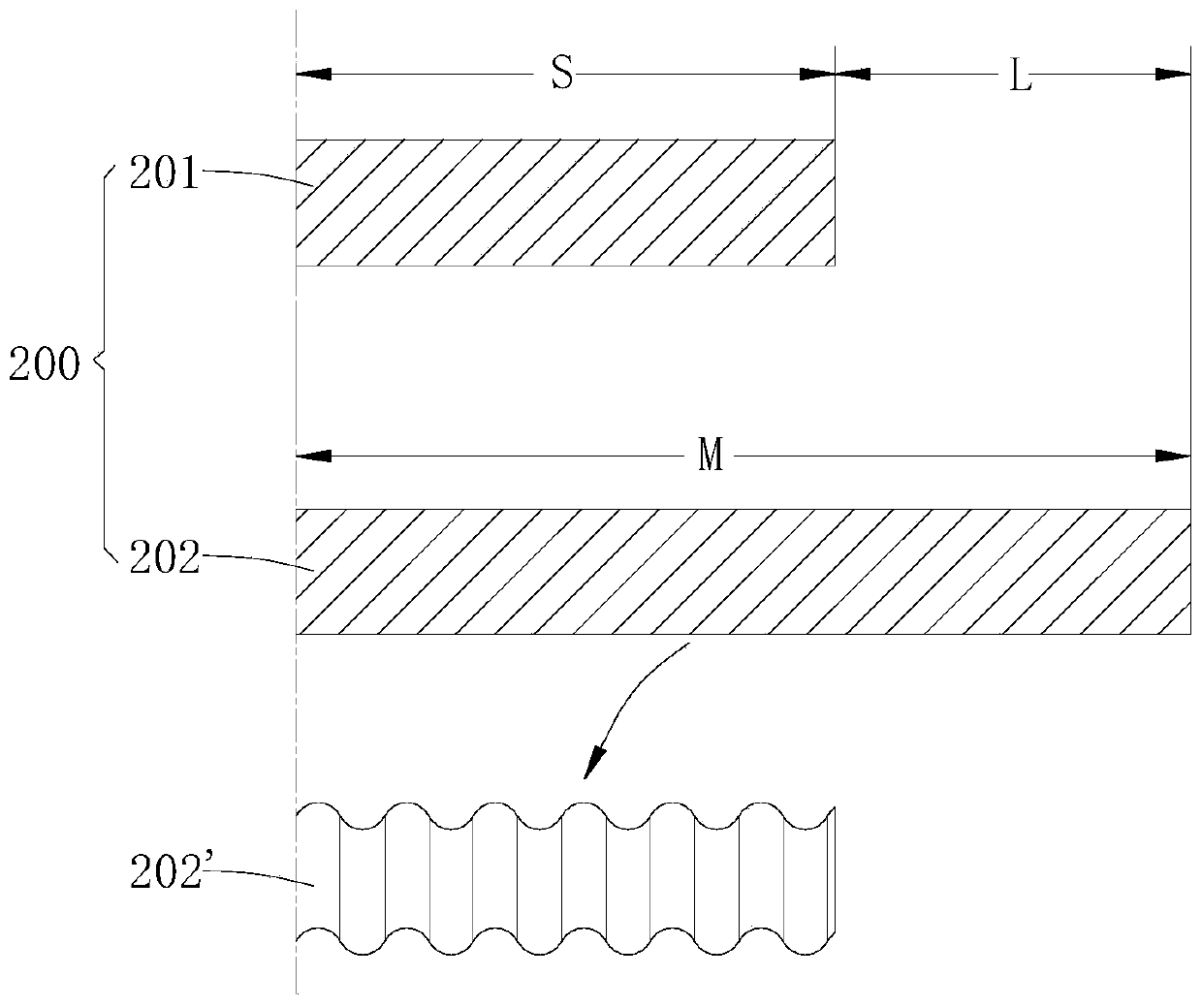

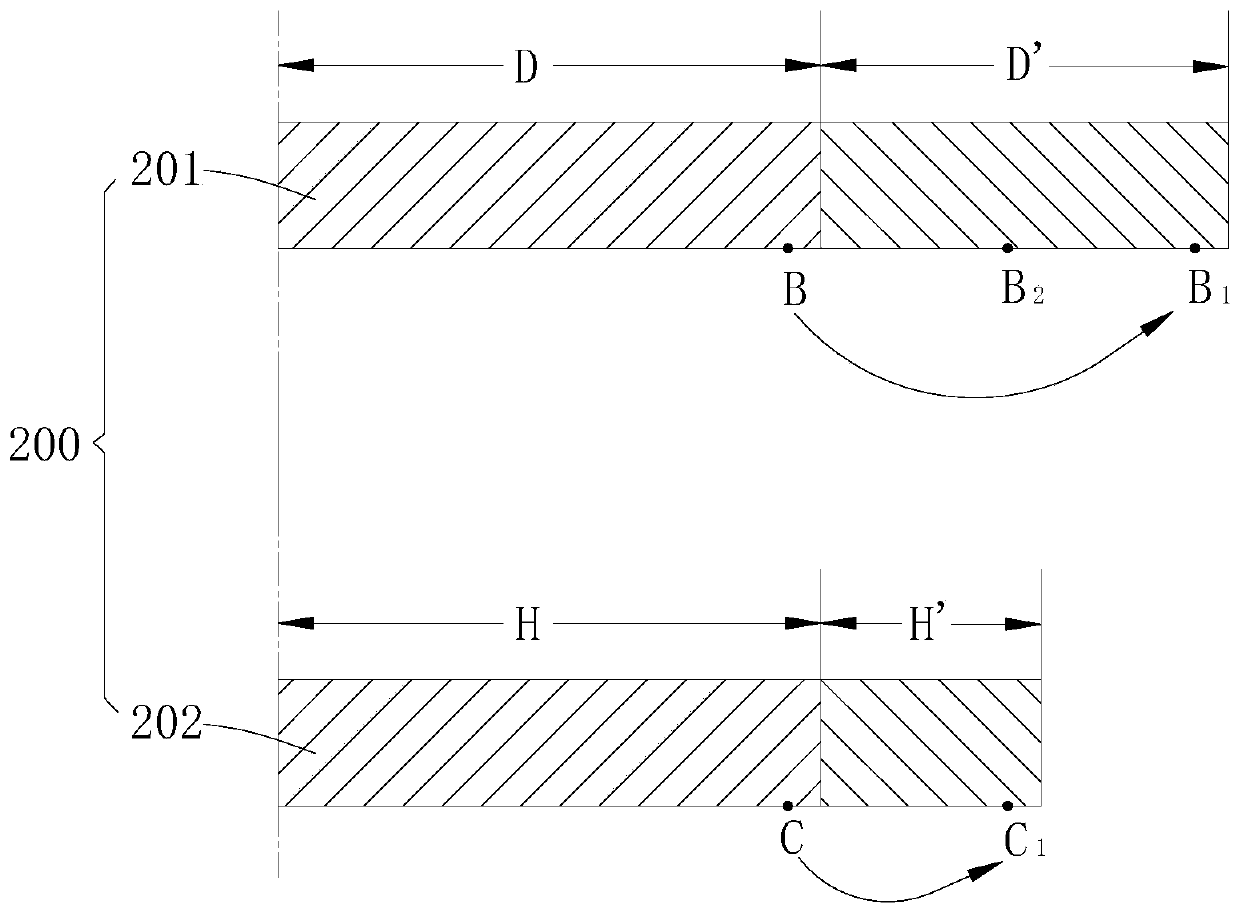

[0037] see figure 1 and figure 2 According to an embodiment of the present invention, a sewing control method S100 for a sewing machine is suitable for sewing tubular clothes with a folded layer 200. The sewing control method S100 for a sewing machine includes: sewing the rotating folded layer 200 by a sewing needle assembly, A rotating pressing wheel is arranged on the side of the sewing needle assembly to arrange the outer layer 202 of the folded layer 200. If the circumference M of the outer layer 202 of the folded layer 200 is greater than the circumference S of the inner layer 201 of the folded layer, then The rotation speed of the pressing wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com