A combination method of high-temperature creasing and electric embroidery cutting for shoe production and shoes

A combined method and electric embroidery technology, applied in shoe uppers, footwear, applications, etc., can solve the problems of easy displacement, uneven crumpled cloth, low production efficiency, etc., and achieve simple process production, uniform and smooth creasing, and improved The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

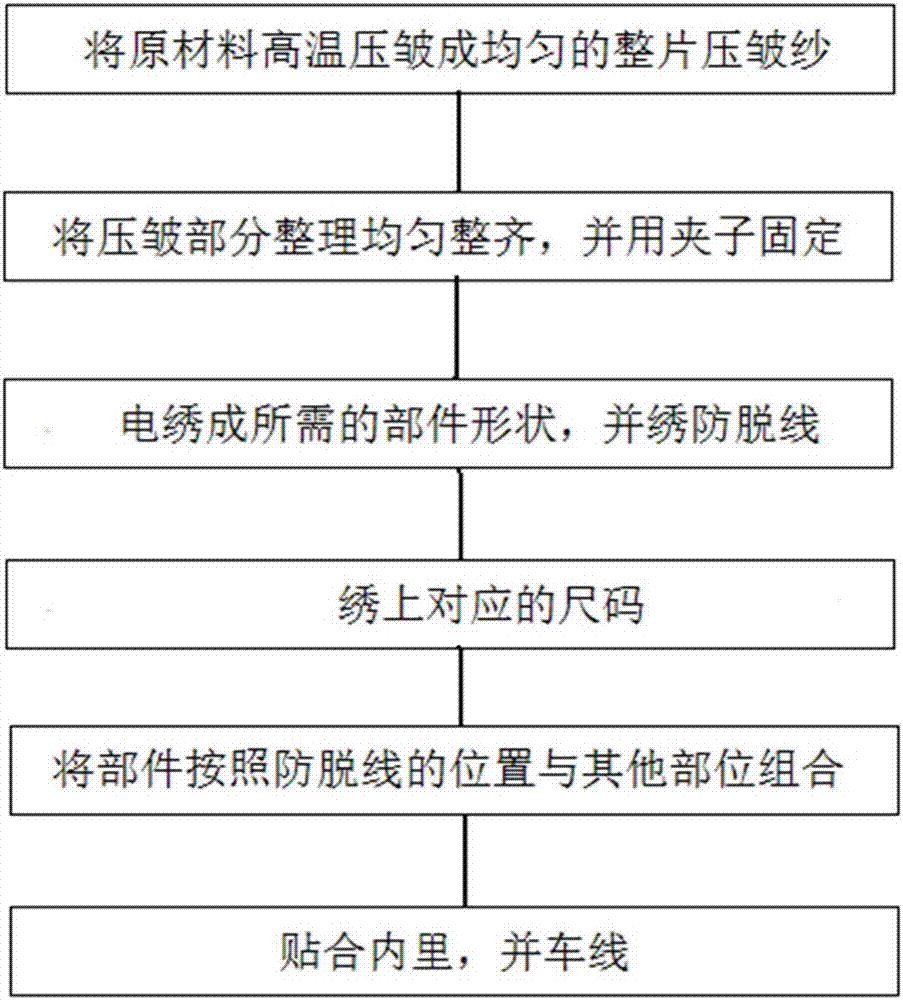

[0017] Such as figure 1 As shown, the present invention is realized in this way, and a kind of high-temperature creasing electric embroidery cutting combined method for shoe production comprises the following steps:

[0018] (1) The raw material encrypted chiffon yarn is pressed into a uniform whole piece of crumpled yarn by high-temperature crumpling; in production, the encrypted chiffon yarn with a raw material of 120D or more is pressed into a large piece of relatively uniform crumpled yarn by high-temperature crumpling crumpled yarn;

[0019] (2) Place the whole piece of crumpled yarn on the grid plate of the electric embroidery machine, first arrange the crumpled part of the whole piece of crumpled yarn evenly and neatly, and then fix the whole piece of crumpled yarn on the grid plate with clips; This step ensures that the creped shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com