Cigarette diversion and supplying device

A technology for bar cigarettes and cigarette filling, which is applied to conveyor control devices, transportation and packaging, conveyor objects, etc., can solve problems such as the mismatch between the structure design of the cigarette filling channel and the sorting mechanism, and achieve simplified structure and improved cigarette filling. Efficiency, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

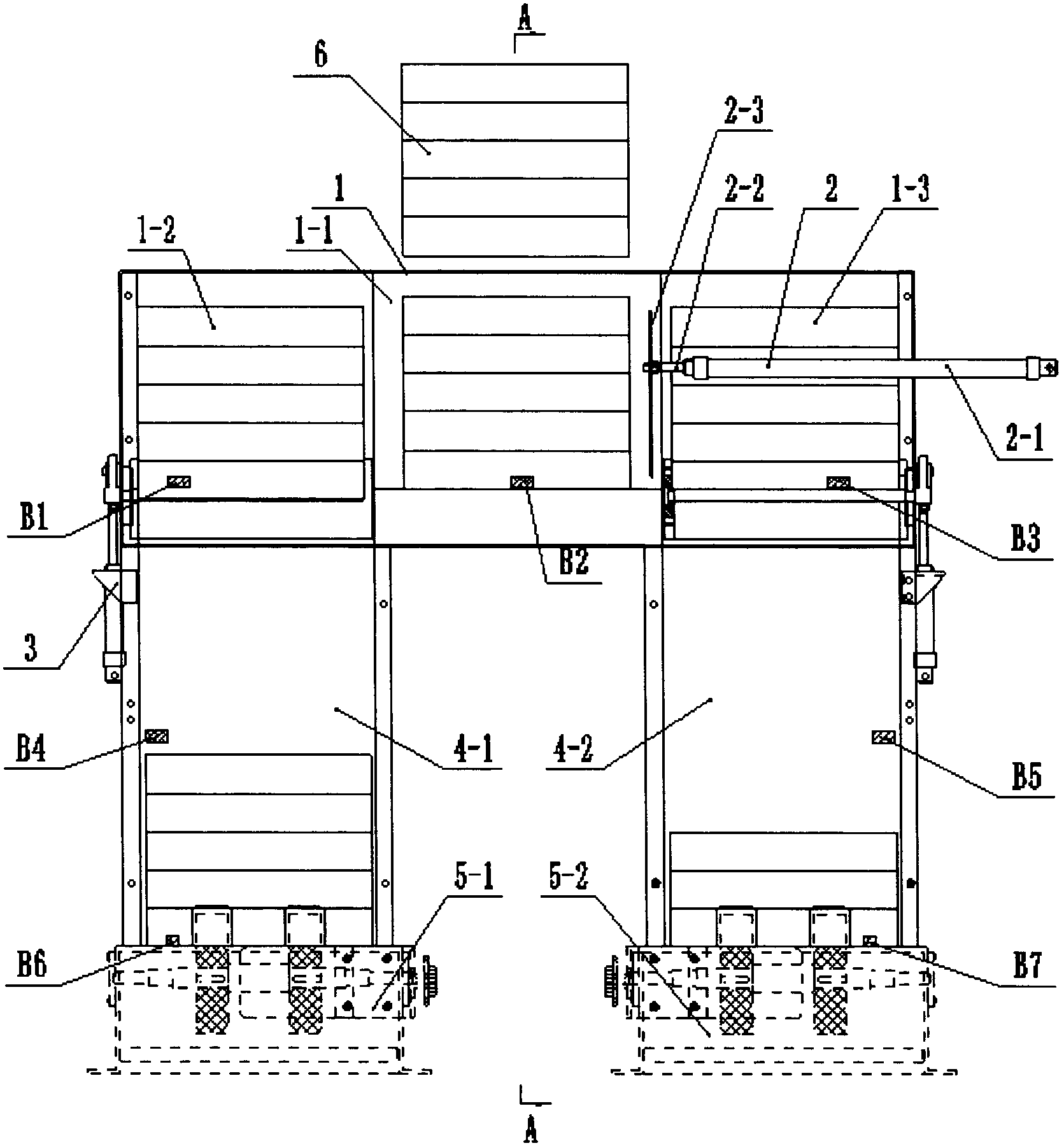

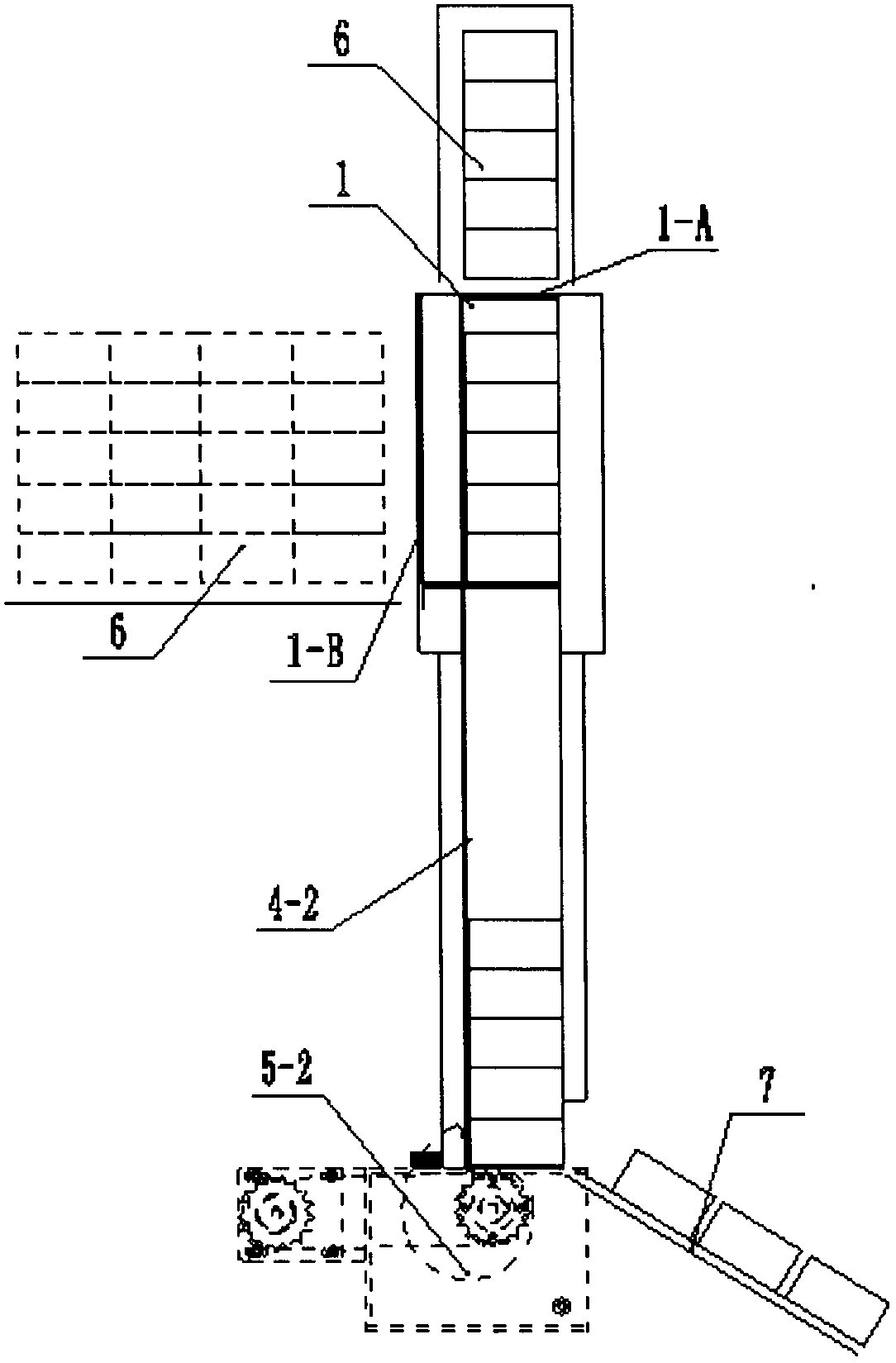

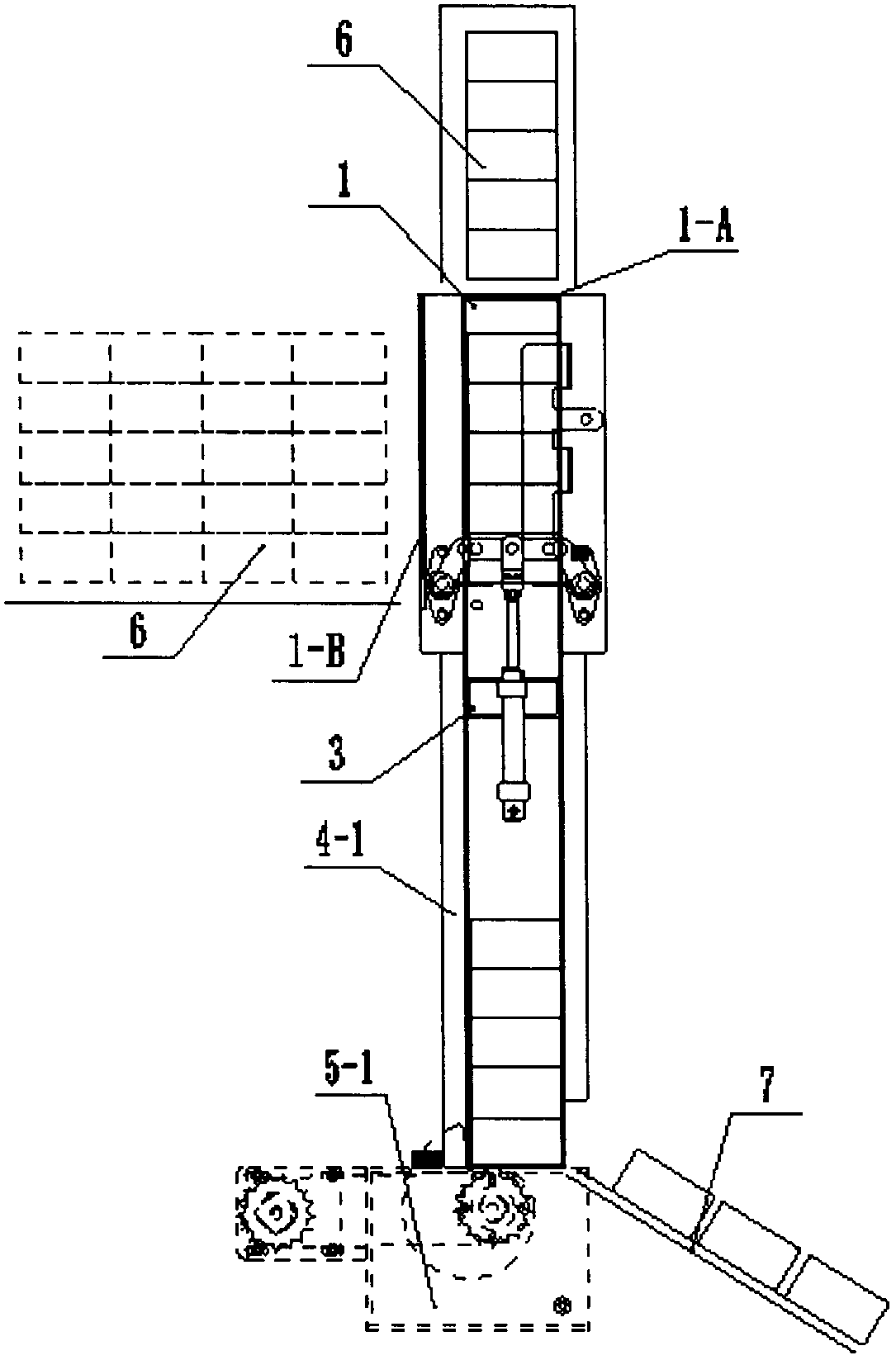

[0026] Attached below Figure 1~4 The implementation process of the present invention is described in detail.

[0027] The invention is installed between the tobacco filling channel and the sorting mechanism of the tobacco sorting system, and is connected with the control system of the sorting system. It is composed of a diversion temporary storage chute 1, a diversion smoking device 2, two cigarette release devices 3, and two buffer storage troughs 4-1 and 4-2; -1. The split temporary storage smoke trough A1-2 and the split temporary smoke storage tank B1-3; the temporary smoke storage trough 1-1 to be split is equipped with an upper smoke filling channel interface 1-A and a side filling smoke channel interface 1-B Distributing smoke pulling device 2 is made of cylinder block 2-1, piston rod 2-2, smoke pulling plate 2-3, and piston rod 2-2 is installed in the cylinder block 2-1, and its moving length is to wait for shunting to temporarily store smoke. The width of the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com