Mechanical stopping device for home elevator

A technology for mechanical blocking and household elevators, applied in elevators, transportation and packaging, etc., can solve the problems of difficult production and installation, no space for installation, small shaft size, etc., to achieve convenient operation, small installation space, and improved safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

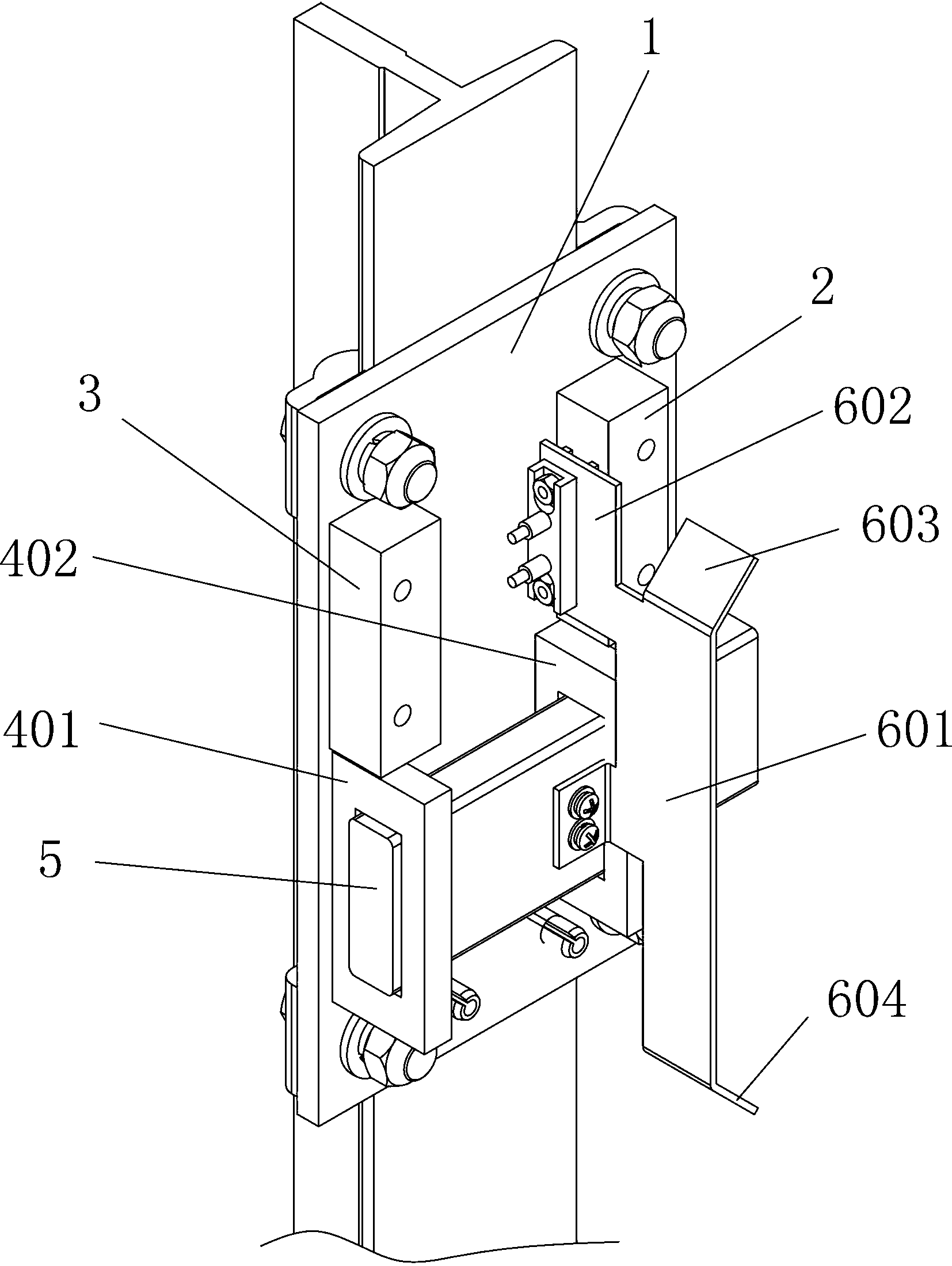

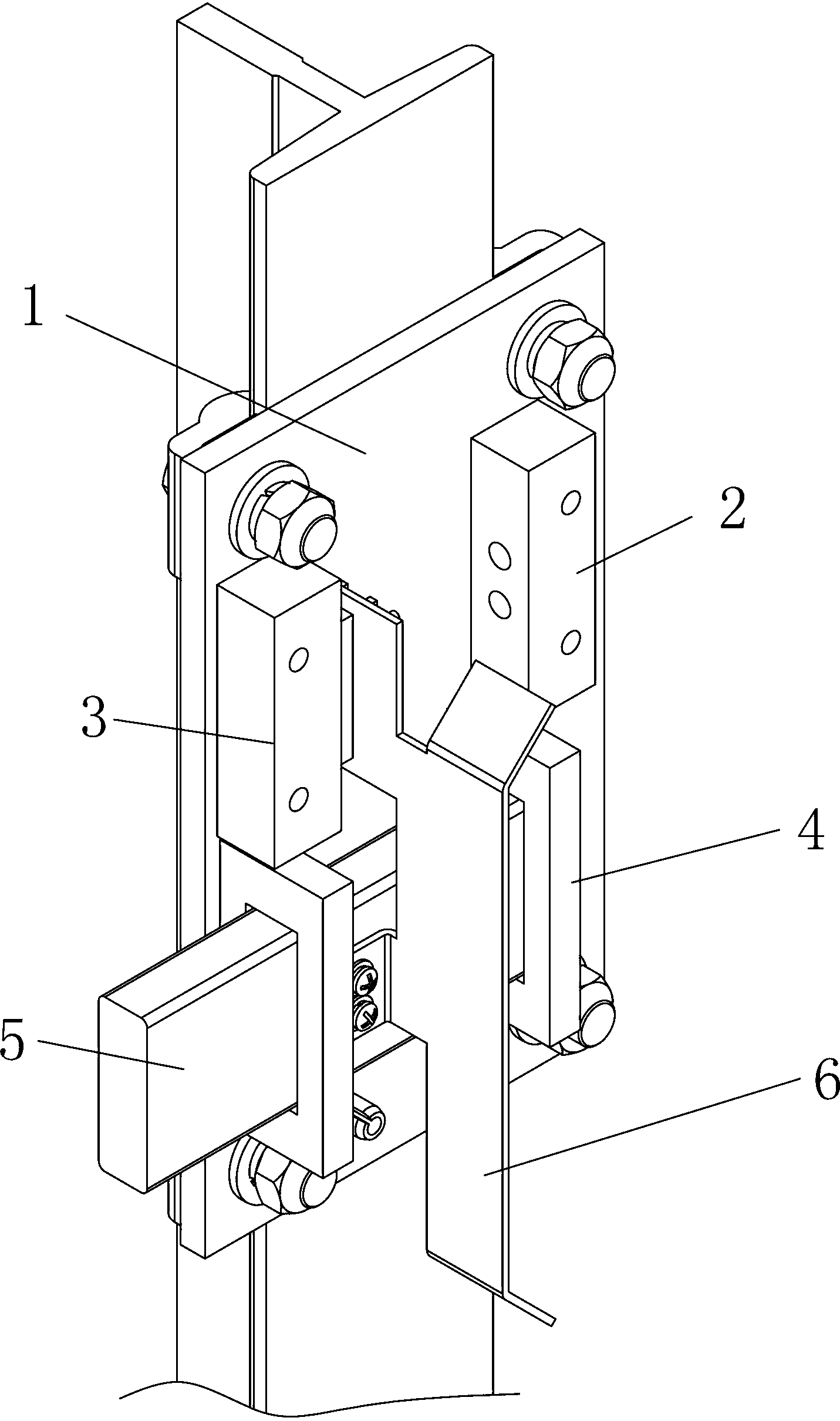

[0041] Embodiment 1, see attached figure 1 , 2 , a mechanical stopping device 1 for a home elevator, including a fixed plate 1, which will be fixedly connected with the guide rails in the elevator in the future, and a home switch 2, an operating switch 3, and a lateral guide 4 are installed on the fixed plate 1, A sliding lance 5 is installed in the transverse guide 4, and a bow 6 is screwed and fixed on the sliding lance 5. The home switch 2 and the working switch 3 adopt mechanical electric contact switches, and can also use proximity switches, etc. The home switch 2 and the working switch 3 are screwed and fixed on the fixed plate 1, and the sliding lance 5 is mounted on the lateral guide part with clearance fit. 4, it can slide freely. In this embodiment, the transverse guide part 4 includes a left frame 401 and a right frame 402 fixed on the fixed plate 1. The left frame 401 and the right frame 402 are screwed or welded on the fixed plate. Above, the sliding lance 5 is ...

Embodiment 2

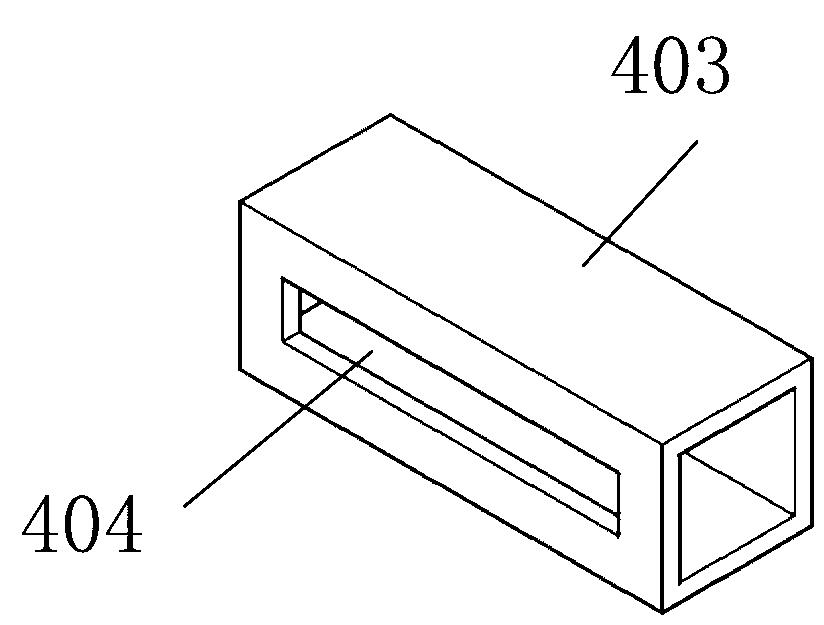

[0047] Embodiment 2, see attached image 3 , the lateral guide part 4 includes a steel pipe 403 fixed on the fixed plate 1, the inner hole of the steel pipe corresponds to the sliding lance 5, in the present embodiment, the steel pipe is a square steel pipe, and the inner hole is rectangular; the surface of the steel pipe 403 is provided with a through groove 404, the through groove can be arranged on the upper surface or side of the steel pipe, the through groove 404 communicates with the inner hole of the steel pipe, and the sliding lance is installed in the steel pipe, and the rest are the same as in embodiment 1.

Embodiment 3

[0048] In Embodiment 3, the transverse guide part 4 may also adopt a dovetail guide rail, and the sliding lance 5 may adopt a plate provided with a dovetail groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com