Mirror board support device of solar trough type power generation system

A support device and power generation system technology, applied in solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems of difficult control of precision, large bolt connection, inconvenient transportation, etc., and achieve reasonable mechanical bending and torsion resistance , Small amount of bolt connection, high assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

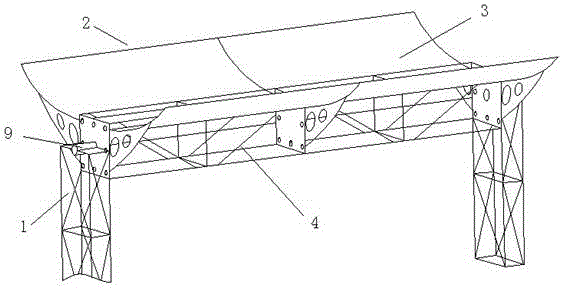

[0023] Such as figure 2 As shown, a solar trough power generation system mirror panel support device of the present invention includes a truss support 1 and a reflector support structure 2 . The mirror supporting structure 2 is arranged on the truss pillars 1 located at both ends of the mirror supporting structure 2 through the rotating parts 9 arranged at both ends thereof, and can rotate around the axis of the rotating part 9 driven by an external driving device. The mirror support structure 2 includes several arc supports 3 and several truss frame units 4 , wherein the arc supports 3 are directly used to support the reflector, and the truss frame units 4 are used for connection and support between the arc supports 3 .

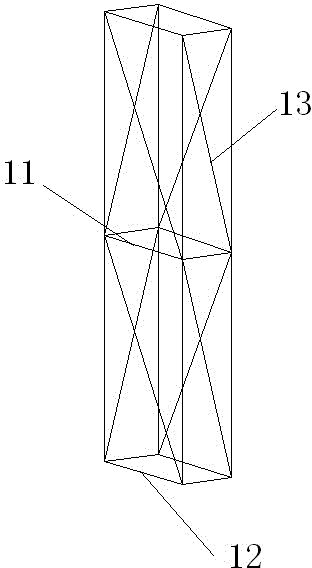

[0024] The truss pillar 1 is fixed on the foundation, such as image 3 As shown, it is a parallel chord truss in which the upper chord 11 and the lower chord 12 are parallel to each other. The upper and lower chords 11 and 12 are distributed at the four co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com