Loading system and method for loading packaged items

A technology for packaging and equipment, which is applied in the field of picking equipment and for picking packages, can solve problems such as high cost, and achieve the effect of improving the independence of packaging type and state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

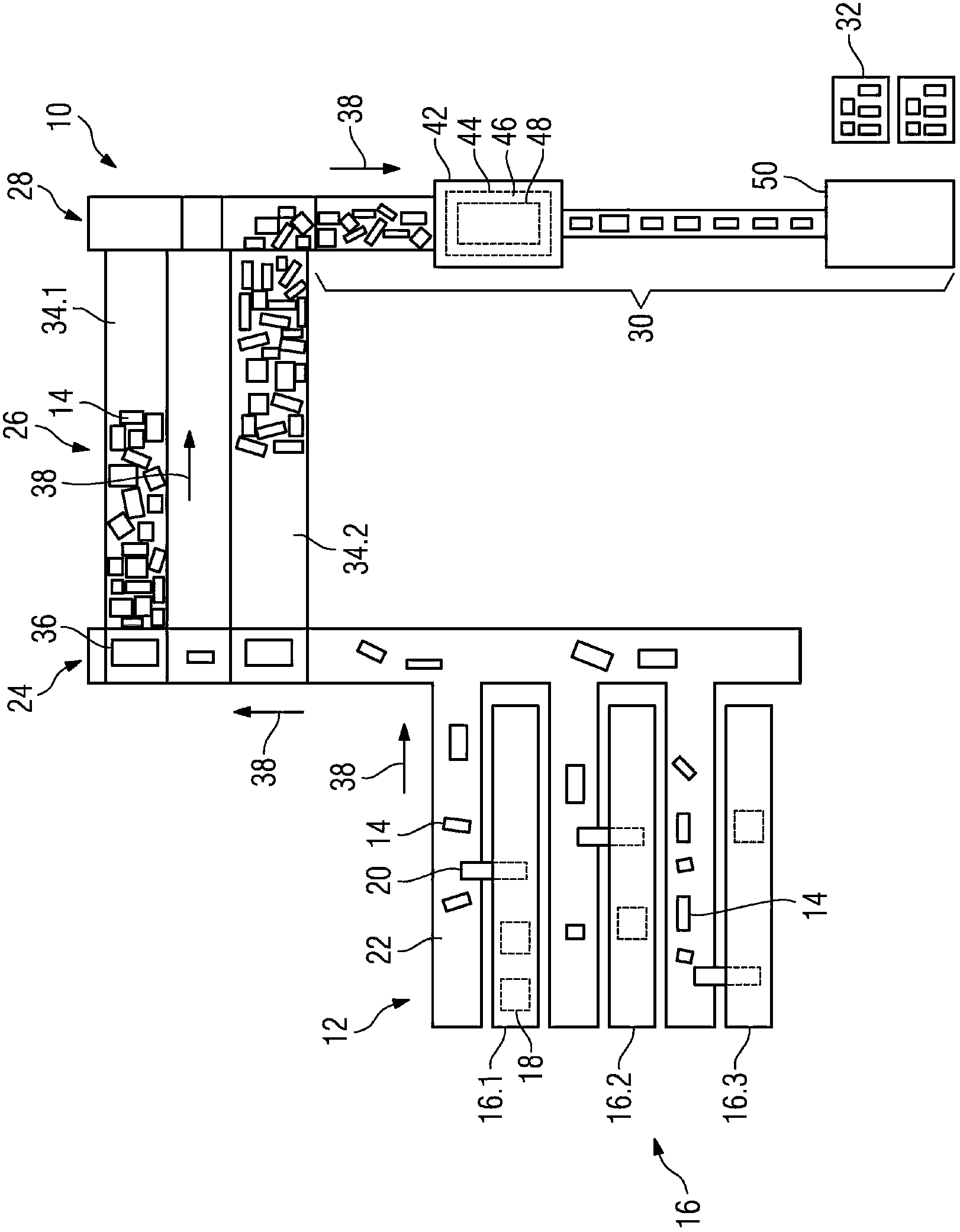

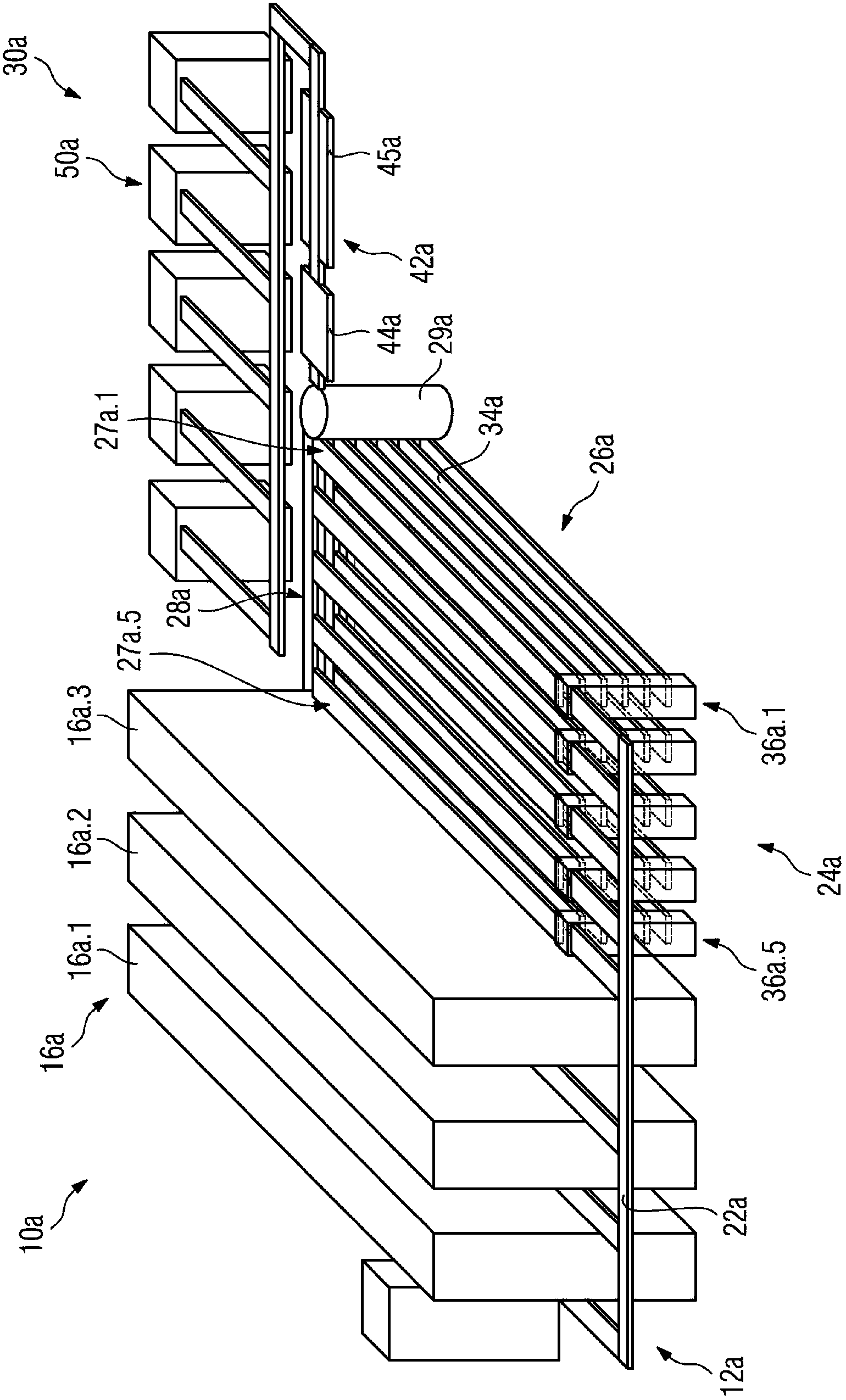

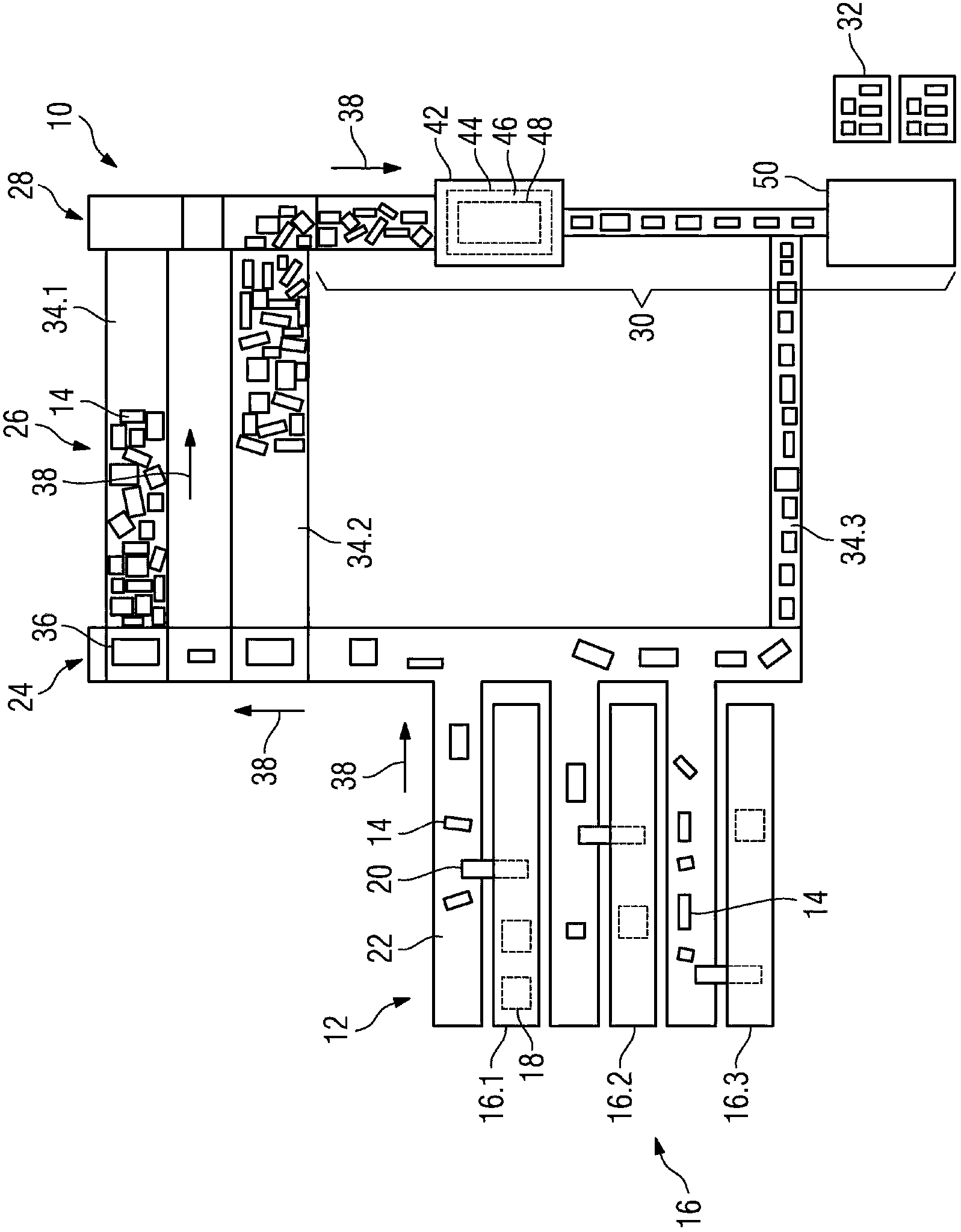

[0024] figure 1 A schematic view of a picking device 10 of a distribution or shipping center is shown from above. The picking plant has a removal device 12 for removing packages 14 from a warehouse 16 . The warehouse 16 is configured as a high-bay warehouse comprising a plurality of rack warehouse units 16.1, 16.2, 16.3. The packages 14 are preferably stored in the rack storage unit directly after their dispatch to the distribution center. For example, in warehouse 16 are stored pallets 18 to which packages 14 are strapped in a conventional manner. The reference number 14 is used uniformly to denote the individual packages, wherein the packages 14 can differ from one another with respect to their shape, weight, packaging material and the like.

[0025] The removal device 12 includes a mechanism 20 for separating the packages 14 , that is to say the individual packages 14 are removed from the pallet 18 . The mechanism 20 can be used for automatic, in particular fully automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com