Camellia oleifera fruit huller

A technology of shelling machine and camellia fruit, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of not easy peeling of fruit shells, small processing capacity, waste of manpower and material resources, etc., and achieves high peeling efficiency and easy peeling. , the effect of easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

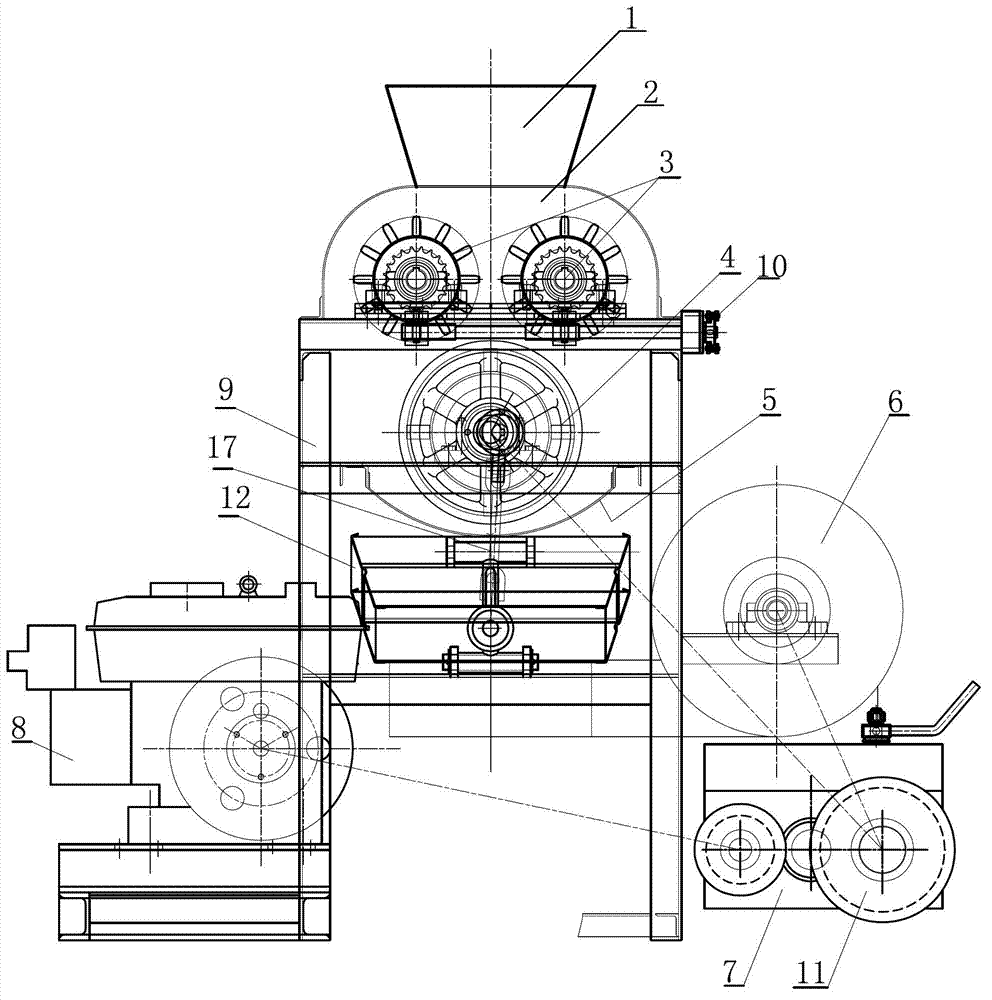

[0016] Embodiment 1: as figure 1 As shown, the present invention comprises frame 9, reversing box 2, two toothed rollers 3, main roller 4, bar sieve 12, semicircle sieve 5 and blower fan 6, and described frame 9 tops are provided with feed inlet 1, in The frame 9 is provided with two relatively rotating toothed rollers 3 relative to the feed port 1, and the two toothed rollers 3 are respectively connected with the reversing box 2, and the main roller 4, the semicircular screen 5 and the strip are arranged in sequence below the two toothed rollers 3. Sieve 12, one end of main roller 4 shafts are connected with the reversing box, fan 6 is arranged on one side of strip sieve 12, and the power machine is diesel engine 8, which is connected with main roller 4 one end and fan 6 respectively.

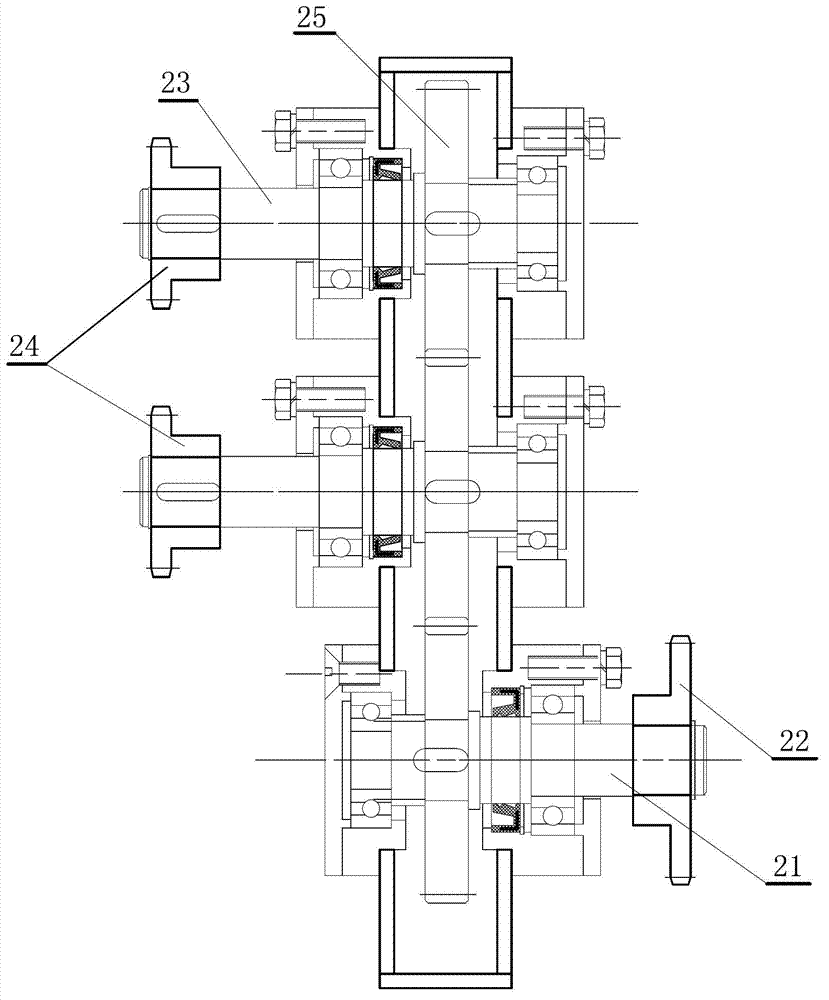

[0017] Such as figure 2 As shown, the steering box 2 includes an input shaft 21 and two relatively rotating output shafts 23. The input shaft 21 and the output shaft 23 are respectively prov...

Embodiment 2

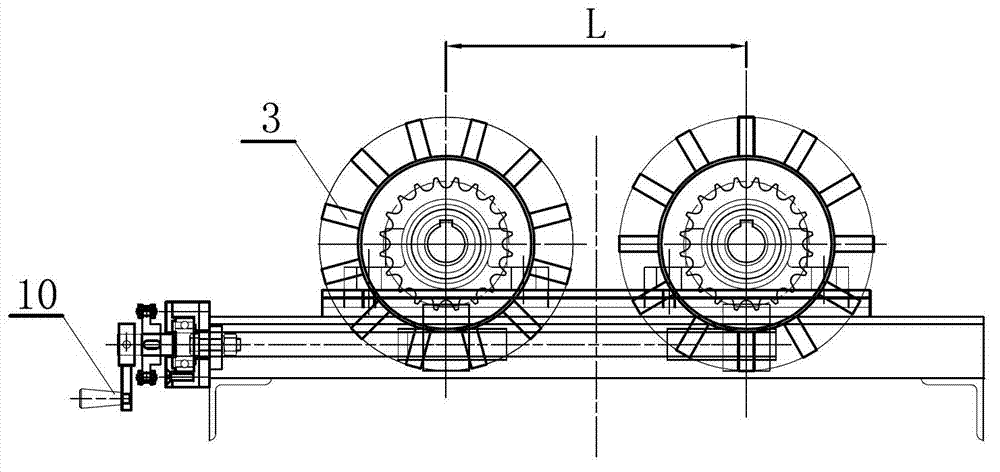

[0021] Embodiment 2: The difference between this example and Embodiment 1 is that the center distance L between the two toothed rollers 3 described in this example is 166 mm; the range of 15-55 mm between the two toothed rollers 3 can be adjusted by the hand wheel 10 . The distance between the main roller and the semicircular screen is 15mm.

Embodiment 3

[0022] Embodiment 3: The center distance L between the two toothed rollers 3 is 180 mm; the range of 15-55 mm between the two toothed rollers 3 can be adjusted by the hand wheel 10; the distance between the main roller and the semicircular sieve is 20 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com