Feeding method of double-spiral roller attrition mill

A refiner and double-screw technology, which is applied in the feeding field of double-screw roller refiners, can solve the problems of large fluctuations in equipment load and affect the service life of double-screw roller refiners, and achieve large conveying capacity, The effect of ensuring the stability of the operation and reducing the fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A kind of feeding method of twin-screw roller refiner of the present invention, it utilizes drum type continuous metering conveyer belt to finish feeding; It comprises the following steps:

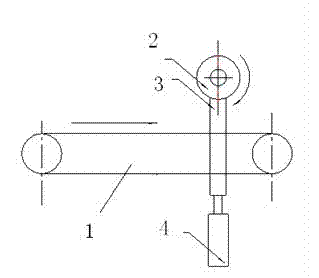

[0015] 1) Send the material to the drum-type continuous metering conveyor belt; the drum-type continuous metering conveyor belt includes a drum 1 and a conveyor belt 2, the conveyor belt 1 is located above the bin of the double-screw roller refiner, and the drum 2 can rotate The drum and the conveyor belt are fixedly arranged on the frame, the conveyor belt is arranged directly above the bin of the double-screw roller refiner, and the rotating shaft of the drum is perpendicular to the conveyor belt; the drum is connected to the driving motor, and the rotation The drum is fixedly connected with the drum bracket, and the drum bracket is vertically slidably arranged on the frame, and the drum bracket is connected with the hydraulic piston rod 3, and the hydraulic piston rod 3 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com