Method for determining thermal crown of hot rolled strip roller

A hot-rolled strip steel and determination method technology, which is applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problem that the initial temperature of the roll cannot be accurately given, and improve the control accuracy of forecasting and shape setting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

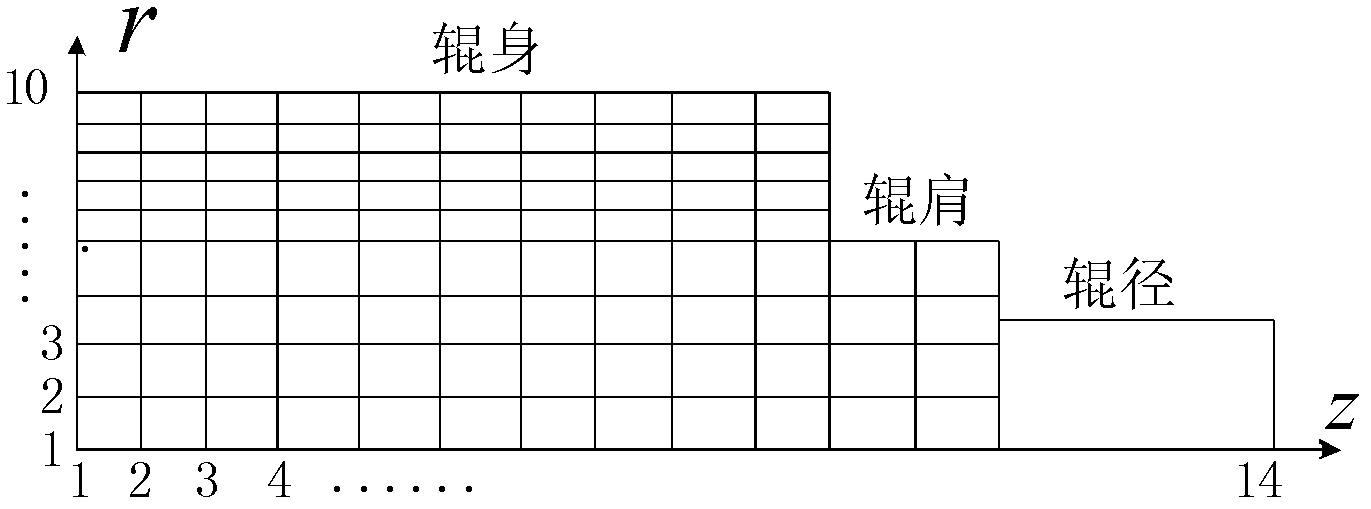

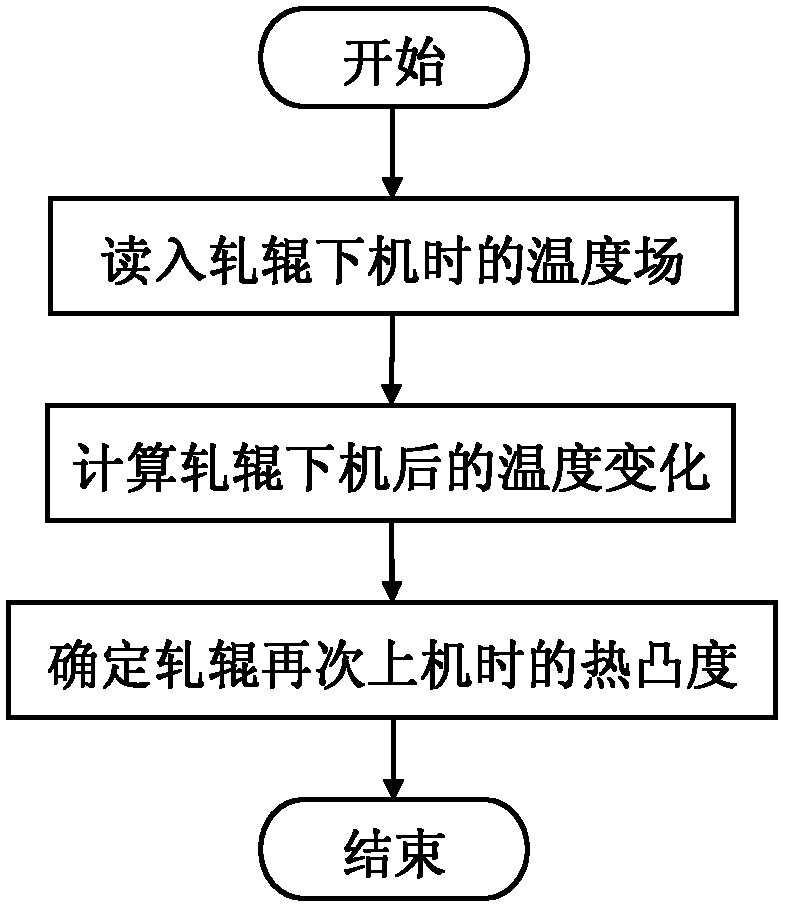

[0096] This method is applicable to the situation that the rolls are not regrinded in the production of hot-rolled strips, and the rolls are put on the machine again after staying for 1 to 5 hours to determine the initial temperature and thermal crown of the rolls.

[0097] The calculation process and results of determining the temperature, thermal expansion and thermal crown changes of the work rolls of the hot rolling mill after being off-machine by the method of the present invention are given below.

[0098] The cooling conditions of the rolls are shown in Table 1, and the thermal physical parameters of the roll materials are shown in Table 2.

[0099] Table 1 Roll Cooling Conditions

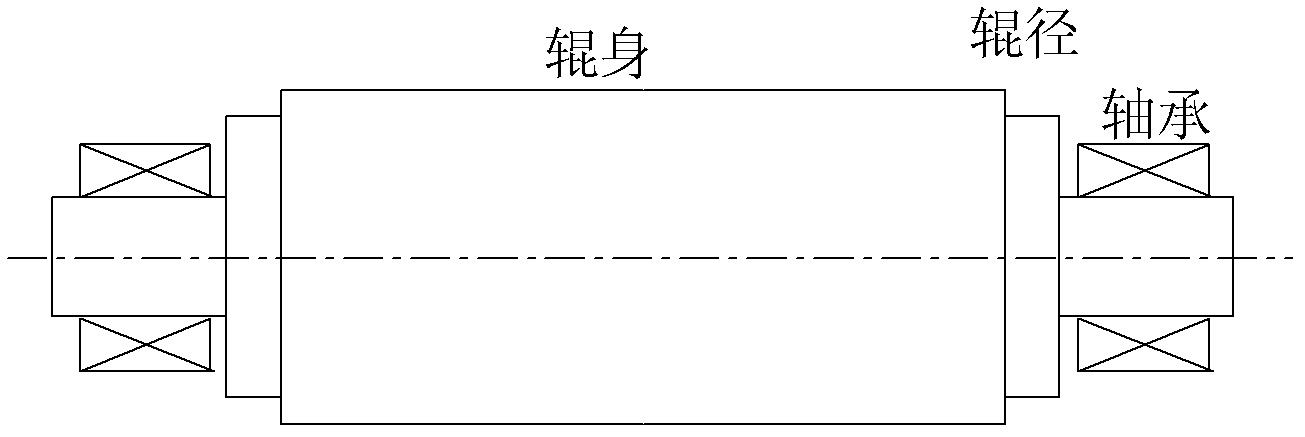

[0100] Roll radius(mm)

397.7

Roller body length (mm)

1780

Roll diameter length (mm)

210

Bearing length (mm)

860

30

Air cooling time (h)

5

[0101] Table 2 Thermal physical parameters o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com