Shearing mechanism for lower chord steel bar of steel bar truss

A shearing mechanism and steel bar truss technology, applied in shearing devices, shearing machine equipment, metal processing equipment, etc., can solve the problems of asynchronous shearing, only one lower chord bar is cut, affecting the production of steel bar trusses, etc. The effect of structural stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

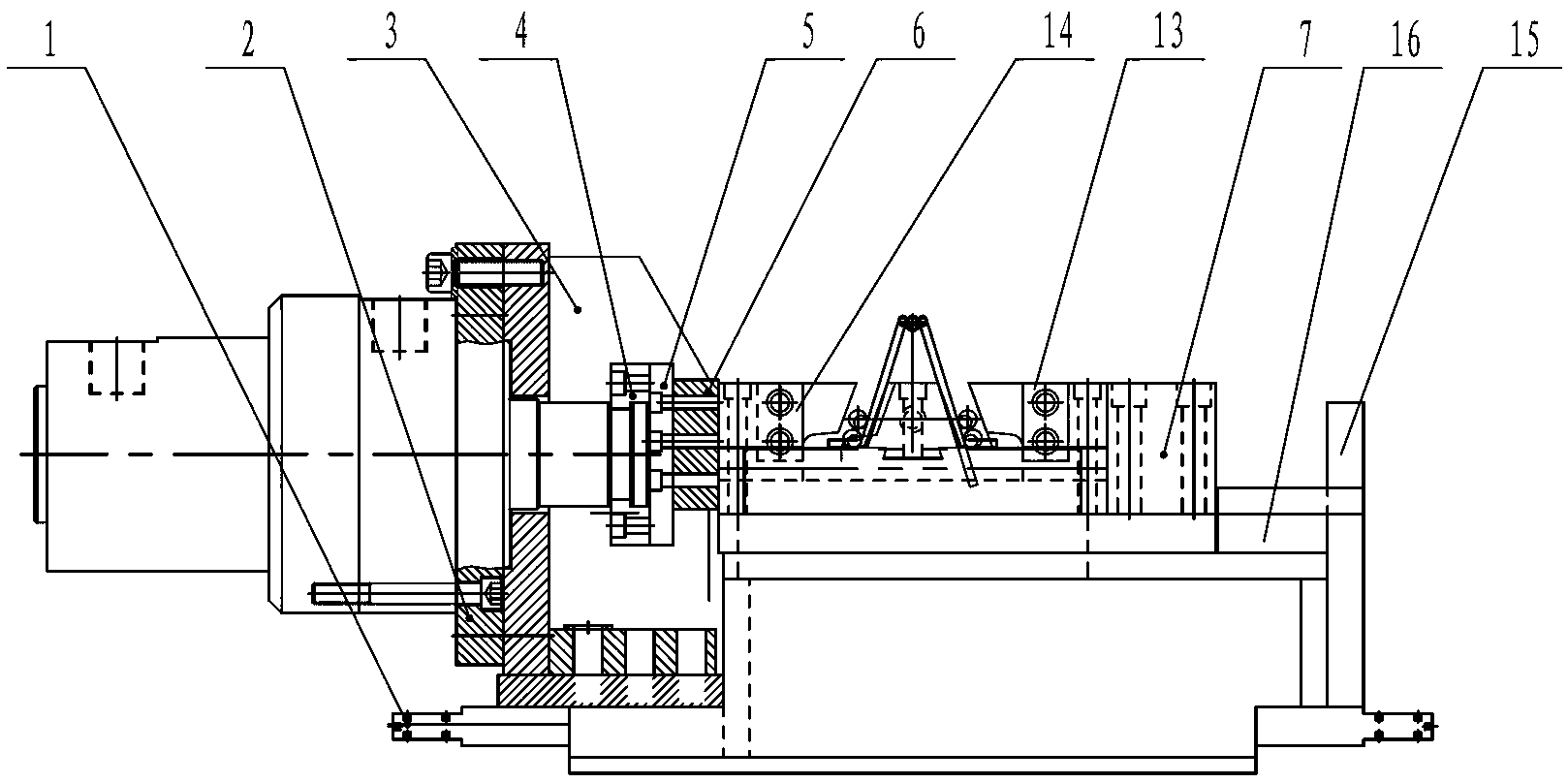

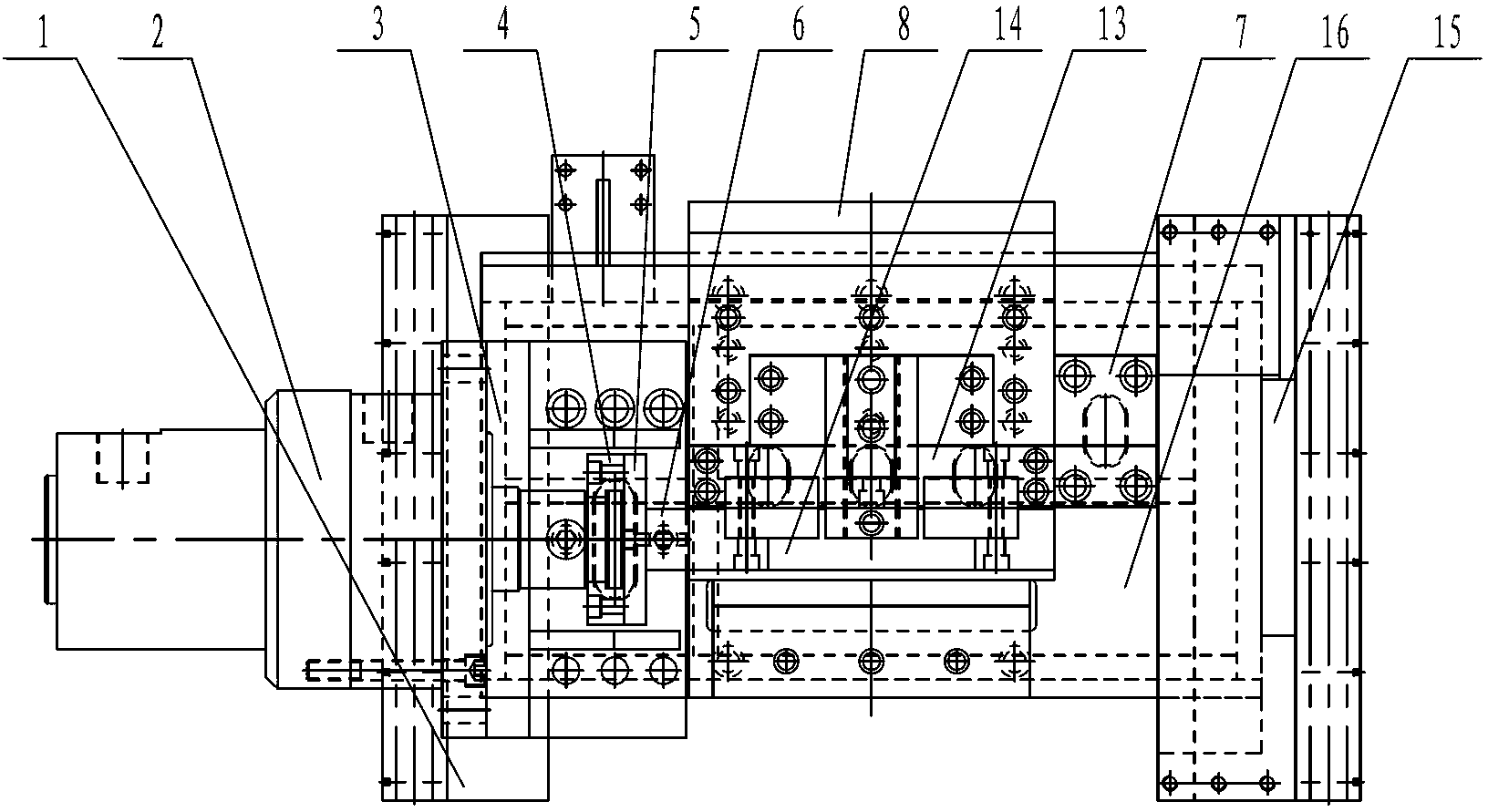

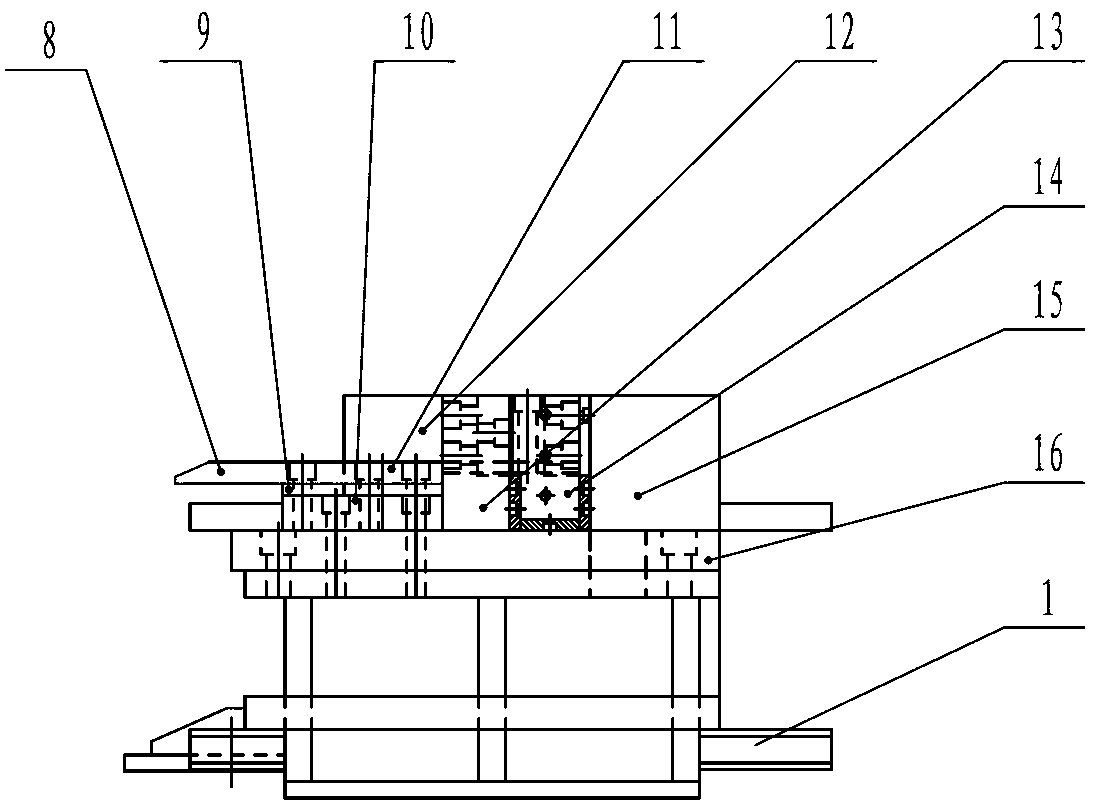

[0012] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Figure 1~Figure 3 Among them, including the lower frame 1, the lower shearing cylinder 2, the cylinder mounting frame 3, the half-moon cover 4, the connecting plate 5, the transition plate 6, the stopper 7, the guide plate 8, the adjusting plate 9, the lower backing plate 10, and the upper backing plate 11. Long fixed body 12, front tool seat assembly 13, rear tool seat assembly 14, limit block 15, large backing plate 16, etc.

[0014] Such as Figure 1~Figure 3 As shown, the present invention is a shearing mechanism for the lower chord bar of a steel bar truss, including a lower frame 1, a lower shear cylinder 2, a front knife block assembly 13 and a rear knife block assembly 14.

[0015] One side of the lower frame 1 is fixed with an oil cylinder mount 3 by screw keying, and the lower shear oil cylinder 2 is horizontally installe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap