Processing method of accordion sound spring

A processing method and an accordion technology, which are applied in the processing field of accordion gongs, can solve the problems that the quality and stability of the gongs cannot be guaranteed, the gap between the gongs and the gong frame is uneven, and the force control of the press is difficult to grasp. Guaranteed intonation, firm riveting, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

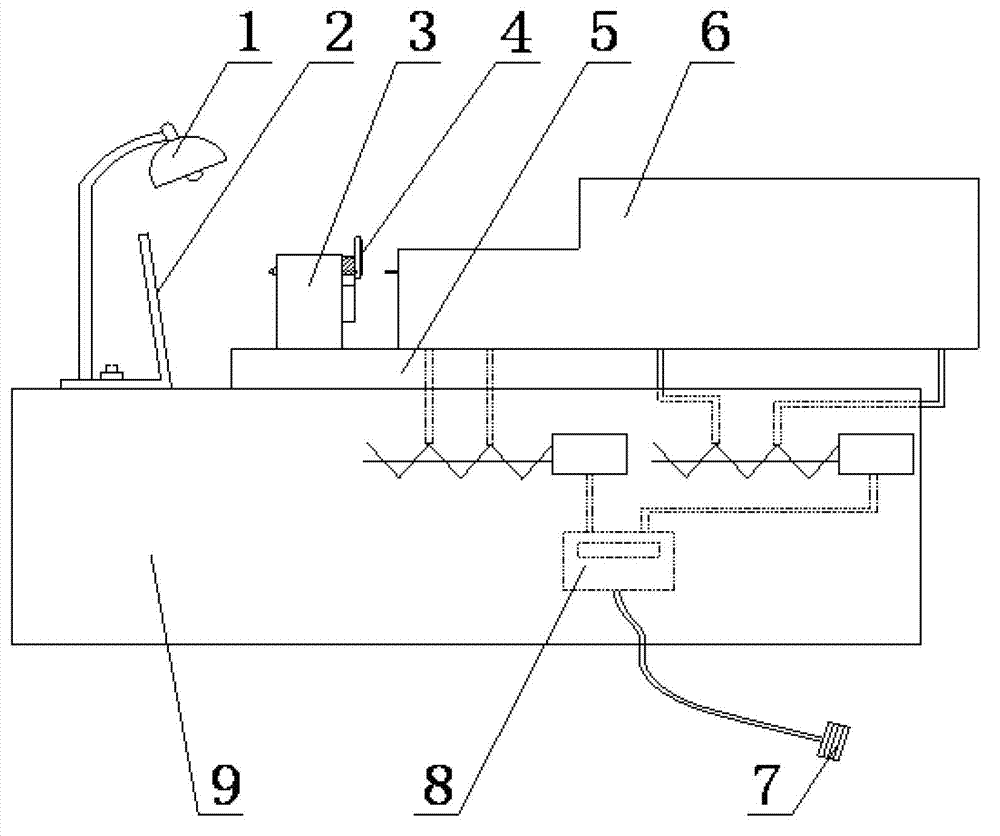

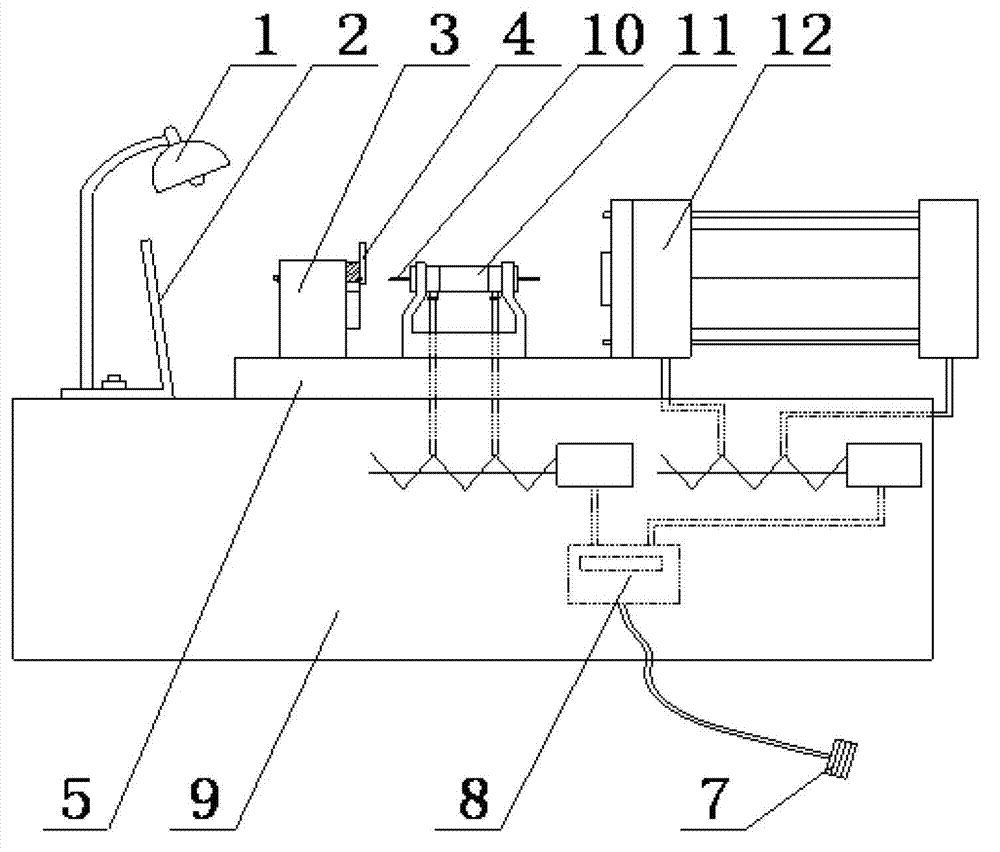

[0028] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0029] A processing method for an accordion gong, the innovation of which is that the steps of the processing method are:

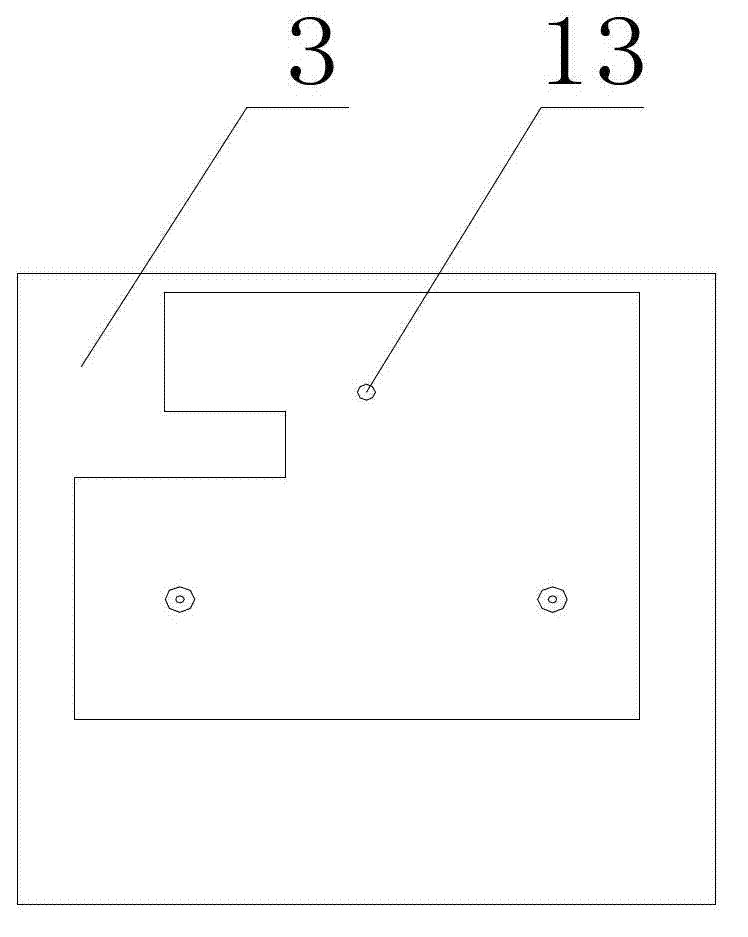

[0030] ⑴. Punching and blanking of sound reed 14: Place the raw material of the sound spring in strips on the punching and blanking machine for punching and blanking to make a sound reed. The head of the sound reed is punched and formed with rivets Mounting holes;

[0031] (2) Assemble the gong frame 15 with the rivet: use a rivet machine to put the rivet in the rivet hole made on the formed gong frame, and the rivet and the gong frame are closely fitted and fixed;

[0032] ⑶. Adjustment and riveting of the sound reed and the gong frame: the adjustment and riveting of the sound reed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com