Cucurbit flute

A gourd silk and sound tube technology, applied in the field of reed wind instruments, can solve the problems of unbalanced gas flow in gourds, affect the quality of pronunciation, increase maintenance costs, etc., and achieve the effects of preventing damage to the inner wall, preventing airflow from being scattered, and facilitating replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

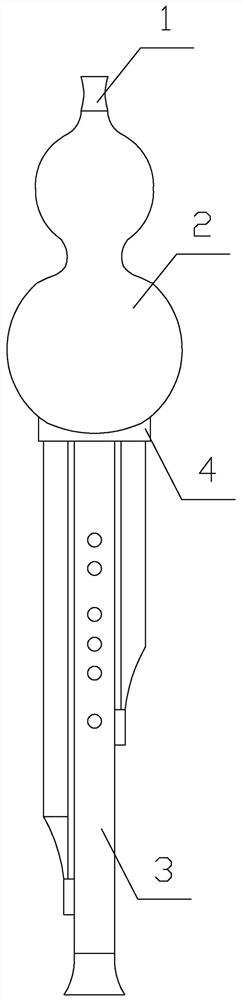

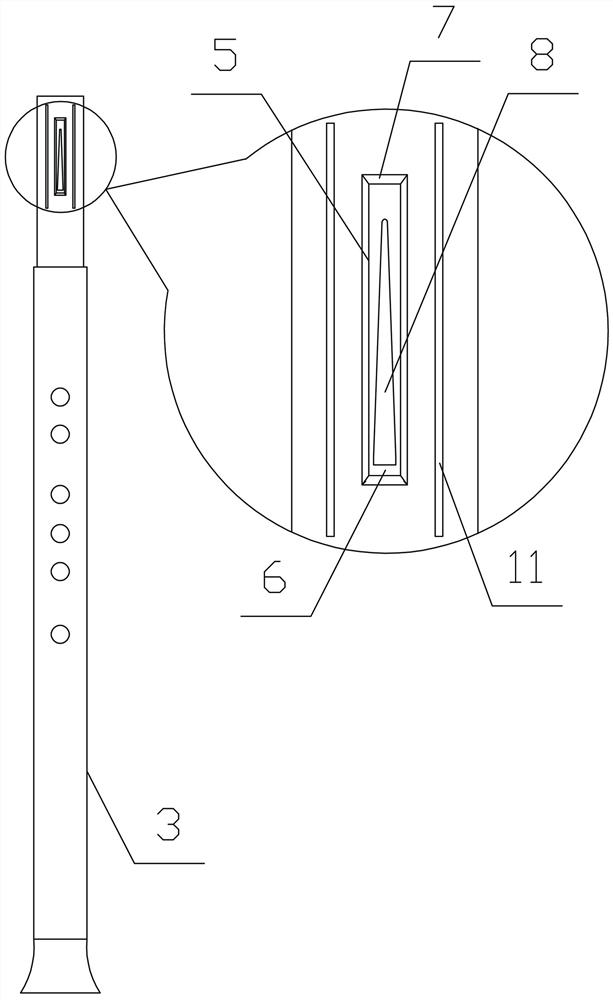

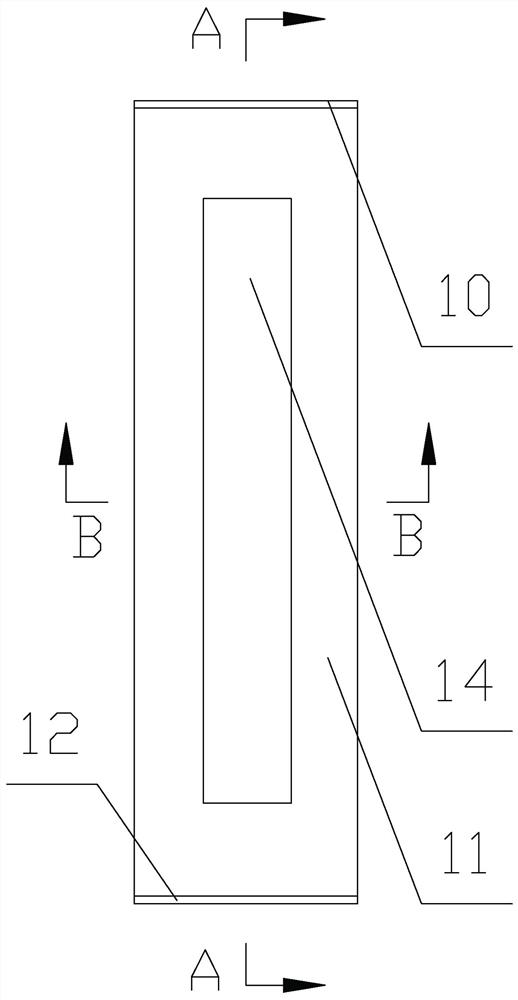

[0035] Such as figure 1 and figure 2 As shown, the application discloses a cucurbit silk, including a mouthpiece 1, a sound bucket 2 and a sound pipe 3, the sound pipe 3 includes a main sound pipe and two and sound pipes located on both sides of the main sound pipe, and the sound pipe 3 is installed on the sound pipe through the interface 4. The lower end of the bucket 2, the first air intake hole 5 and the reed 6 are set at the end where the sound pipe 3 extends into the sound bucket 2, and the airflow guide slope 7 is arranged around the first air intake hole 5, and the extension direction of the airflow guide slope 7 points to The tongue plate 8 of the reed 6 is detachably mounted on the inner side of the first air inlet 5 of the sound pipe 3 through the connection assembly.

[0036] Such as Figure 2 to Figure 5 As shown, the connection assembly includes a socket arranged on the sound pipe and intersecting with the first air inlet 5 and an adapter block tightly fitted i...

Embodiment 2

[0040] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 8 As shown, there are two middle arc-shaped parts 21 of the intima removal assembly, and the size of the upper middle arc-shaped part 21 is larger than the size of the lower middle arc-shaped part 21. When this embodiment is used, the endometrium removal assembly Insert from the interface opening at the bottom of the sound bucket, the small-sized middle arc part extends into the small cavity of the sound bucket and contacts the inner wall of the sound bucket, and the large-sized middle arc part is located in the large cavity of the sound bucket and It is in contact with the inner membrane of the inner wall of the sound bucket, and the membrane is removed by rotating under the drive of the electric drill.

Embodiment 3

[0042] The structure of this embodiment is basically the same as that of Implementation 1, the difference is: as Figure 9 As shown, a moisture-proof layer 27 is set on the upper end of the interface 4 (at the end inside the audio bucket 2). The moisture-proof layer 27 can be made of a water-absorbing material in the prior art, such as a polymer water-absorbing resin with a thickness of 1 mm. The moisture-proof layer 27 is set on The outer side of the sound tube 3 is in contact with the upper end of the interface 4, and the edge of the moisture-proof layer 27 can be glued to the interface 4. This embodiment can reduce the exhaled moist air without affecting the flow or flow direction of the gas in the sound bucket. Negative effects on the reed or the sound bucket, such as reed oxidation, moldy sound bucket, etc., prolong the maintenance cycle of the cucurbit silk, and during maintenance, the moisture-proof layer 27 is easy to disassemble and assemble, which has a time-saving an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com