Cutting machine with cutting clamp

A technology of clamping device and cutting machine, which is applied in the direction of shearing device, cutter for shearing machine, accessory device of shearing machine, etc., which can solve the problem of uneven cutting length and cutting weight, and the inability to produce blanks uniformly and constantly , Unable to stabilize the blank cutting accuracy and other problems, to achieve the effect of eliminating the rebound phenomenon, stably manufacturing parts, and uniform weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1~3

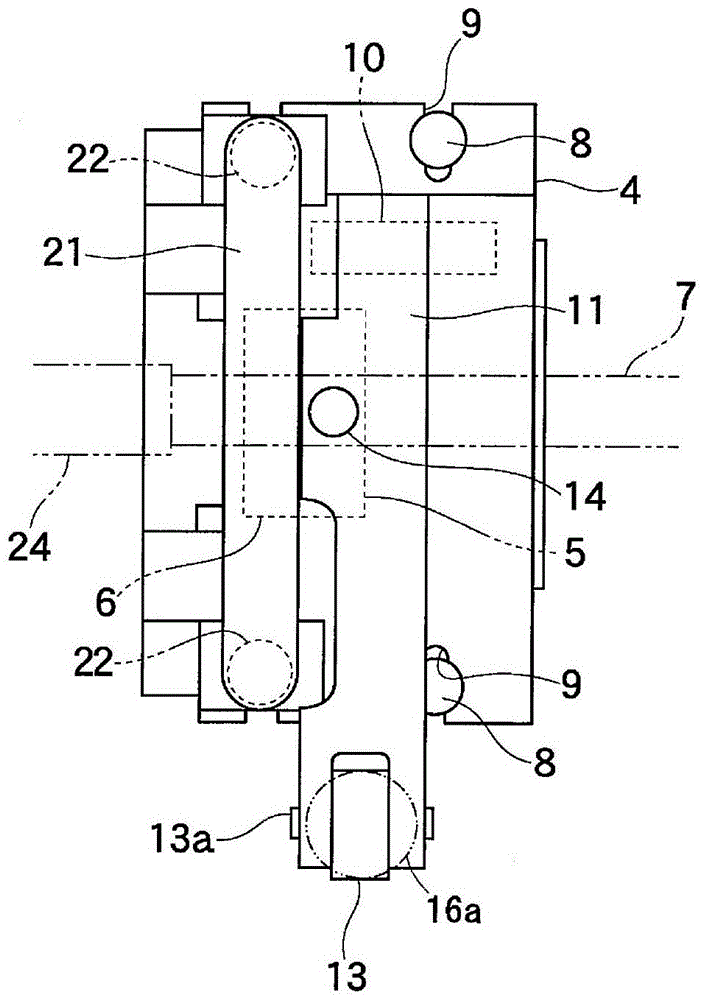

[0058] according to Figure 6-8 Other embodiments 1 to 3 of the clamp cutting device will be described. In addition, in the description of these other embodiments 1 to 3, the same reference numerals are assigned to the same components as those in the above-mentioned embodiment, and detailed description thereof will be omitted.

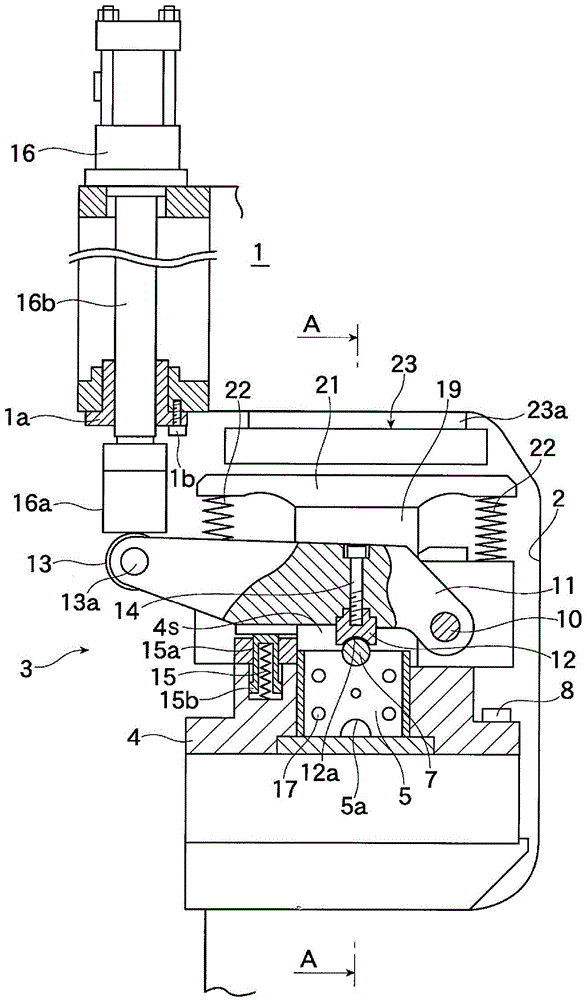

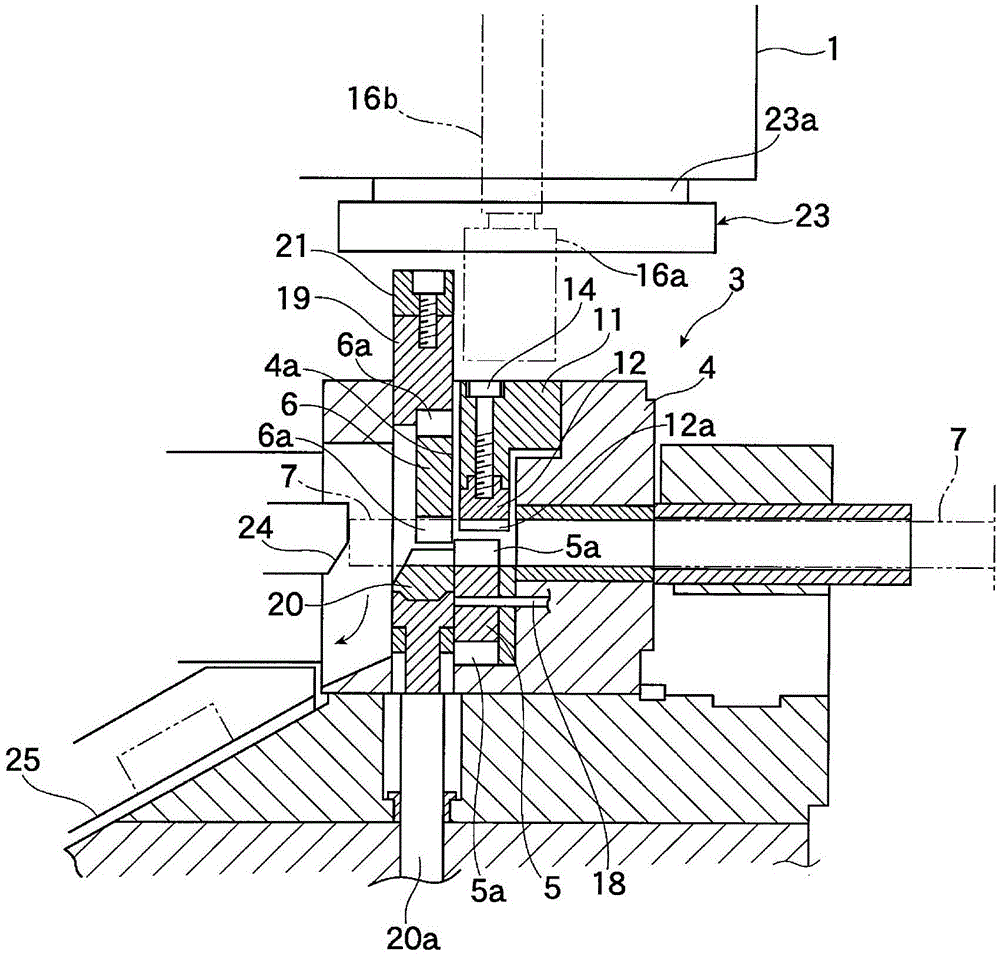

[0059] Figure 6 It shows the cutting machine provided with the cutting clamp device of other Embodiment 1, and is a front view which shows the rod-shaped cutting clamp device which provided the shaft body in the main body side. according to Figure 6 Another embodiment 1 of the clamp cutting device will be described.

[0060] In the above description, the case where the shaft body 10 as a fulcrum for swinging the lever 11 is provided on the base 4 has been described, but the shaft body 10 may be provided on the main body 1 side. Figure 6 as an example. The bearing member 26 is fixed to the wall surface of the recessed part 2 of the main body 1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com