Device for automatically propelling screw into pipe

A screw and automatic technology, applied in screwdrivers, wrenches, manufacturing tools, etc., to achieve the effect of improving construction efficiency and broadening market space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

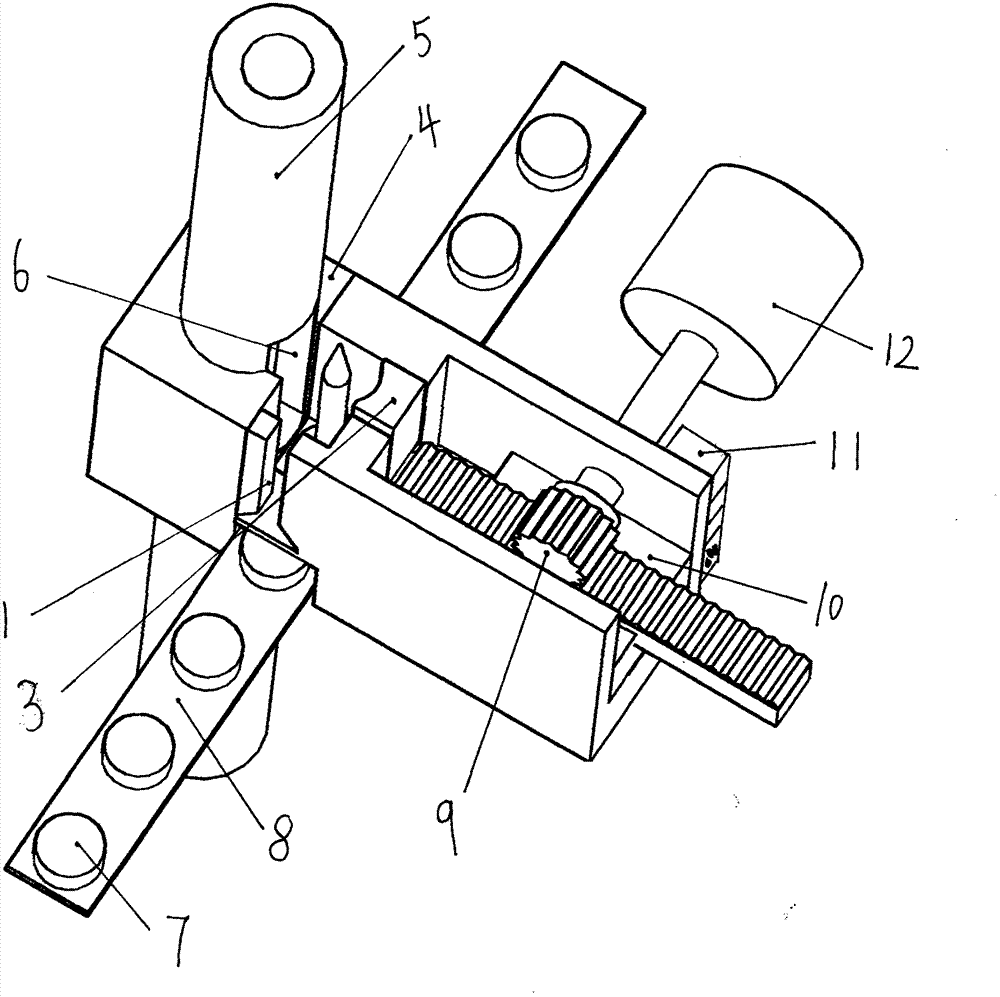

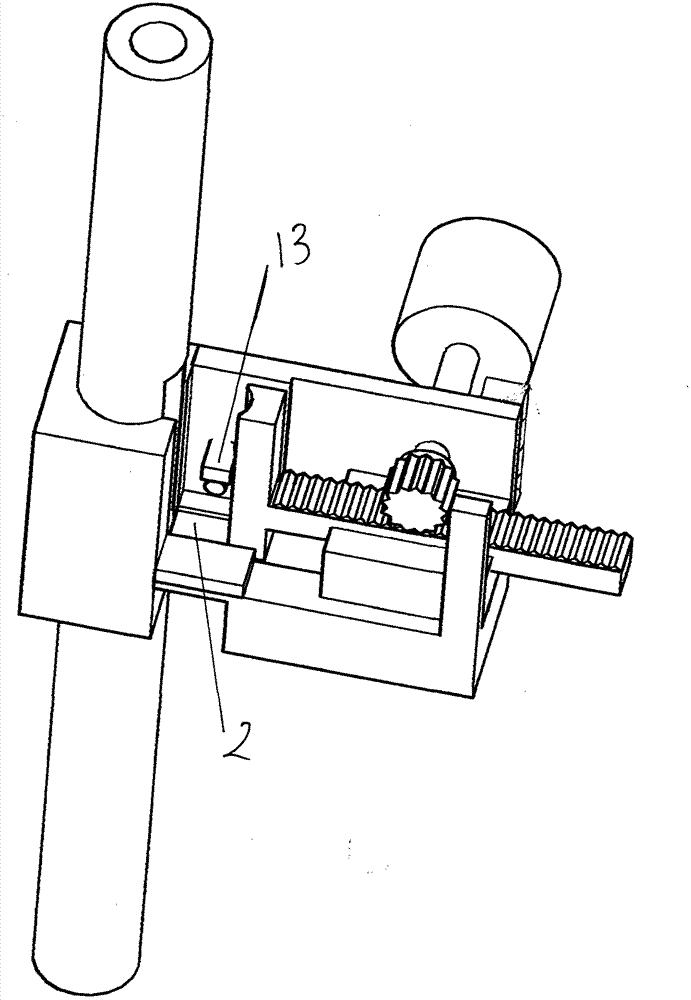

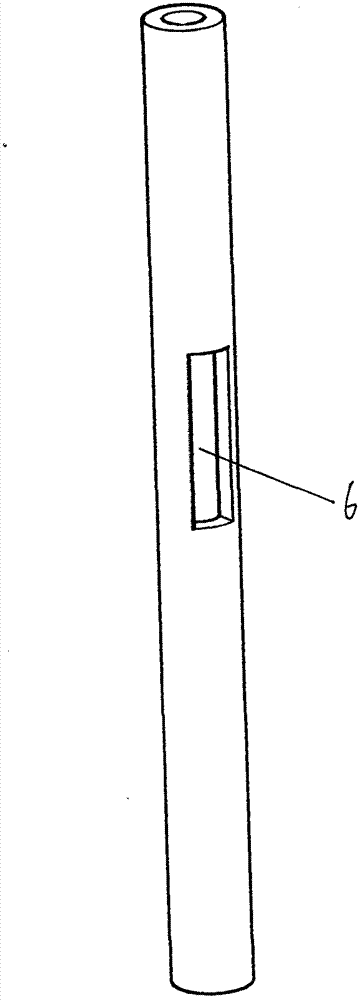

[0015] A screw automatic pipe insertion device, including dovetail groove 1, groove 2, concave semicircular block 3, fixing seat 4, screw feeding pipe 5, window 6, magnet 7, belt 8, rack and pinion mechanism 9, slide rail mechanism 10. Control system 11, motor 12 and sensor 13, the screw tube 5 is inserted into the through hole of the fixing seat 4, one side of the fixing seat 4 is provided with a dovetail groove 1, and the other side is provided with a sensor 13; the screw tube 5 is provided A window 6 is opened on the top, and its size is equivalent to the cross-sectional size of the screw, so that the screw can enter loosely; a groove 2 is provided on the fixing seat 4 facing the window 6, so that after the screw enters the groove 2, it reaches the position facing the window 6 , so that the concave semicircular block 3 pushes the screw into the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com