Fully automatic fruit foaming mesh belt packaging machine

A technology of foaming nets and packaging machines, which is applied in packaging, food packaging, transportation and packaging, etc., and can solve the problems of large size differences of fruits, low operating efficiency, and rising fruit production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

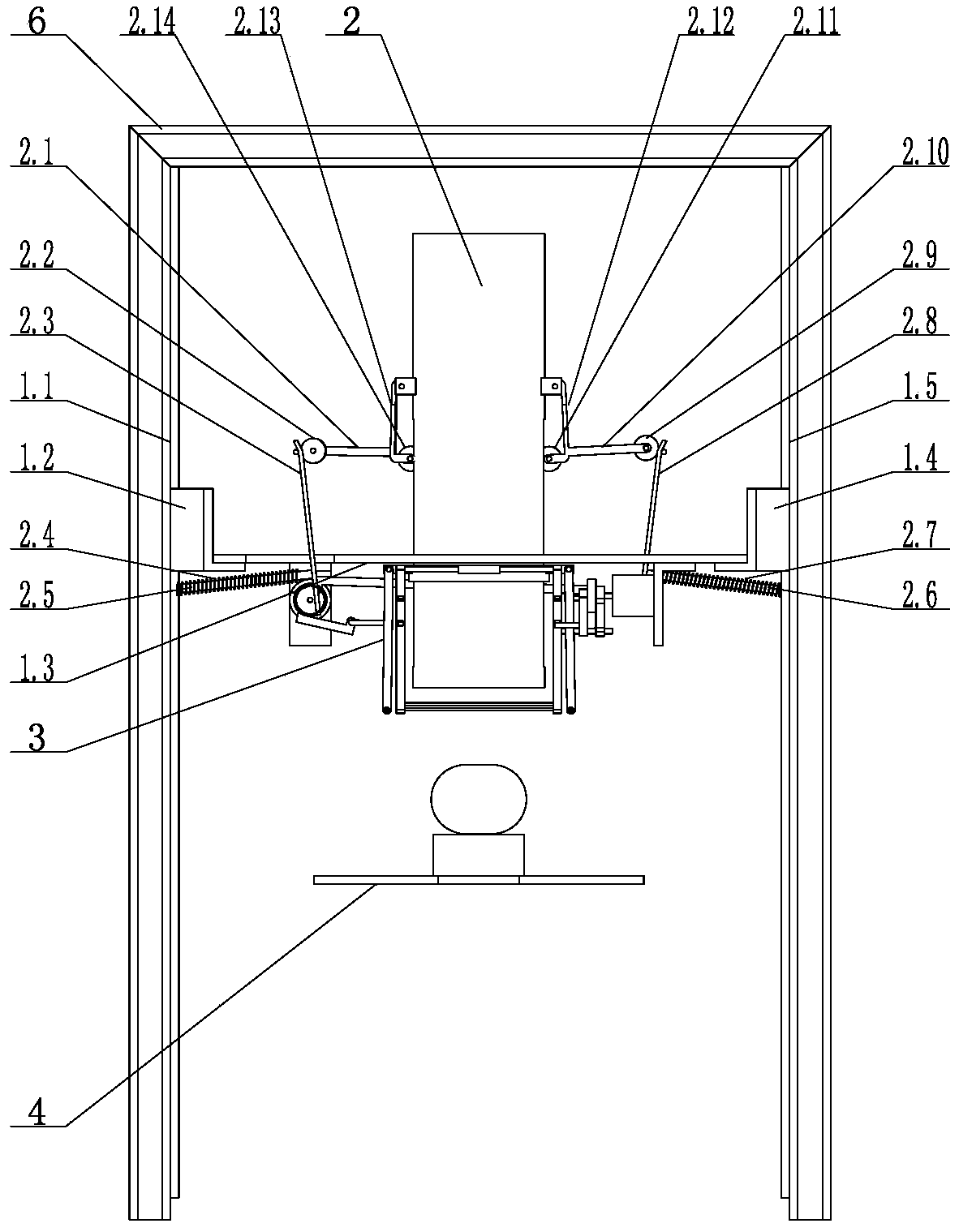

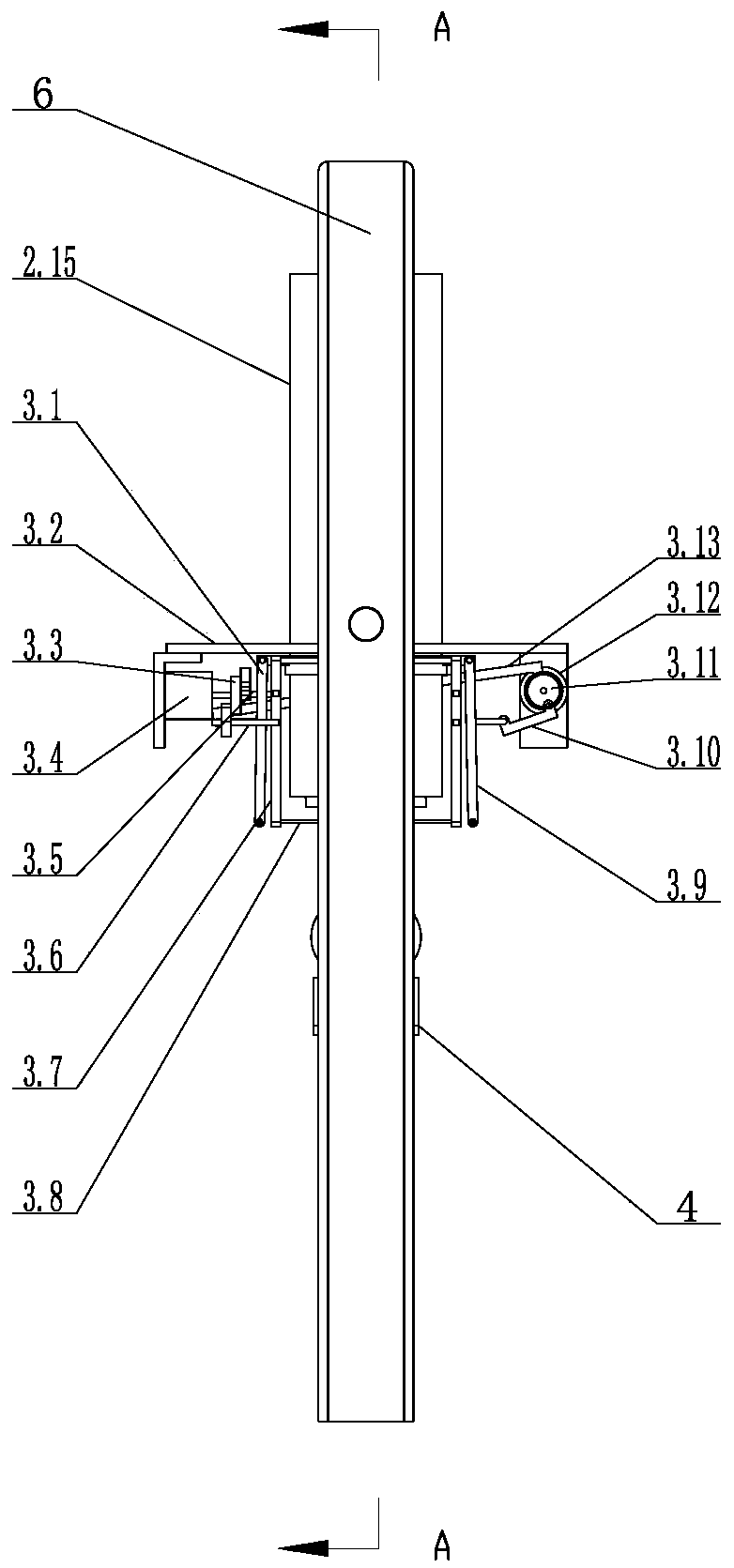

[0068] Such as figure 1 , 2 , 3 and 4, a kind of fully automatic fruit foaming mesh belt packaging machine of the present invention includes a frame and a transmission device, and the transmission device includes a transmission chain; the middle part of the frame is provided with a fruit packaging position, and the The conveying chain passes through the fruit packaging position; the lifting chain plate is installed and fixed on the conveying chain; the upper netting mechanism is set on the upper part of the frame, and the upper netting mechanism is set above the conveying chain; the upper netting mechanism is controlled by the netting power mechanism drive up and down; the upper netting mechanism includes an upper mold cylinder and an upper mold core, the upper end of the upper mold core is arc-shaped, an outer convex ring is set on the upper periphery of the upper mold core, and an inner ring is set on the inner wall of the upper mold cylinder. The convex ring, the upper mol...

Embodiment 2

[0086] This embodiment is different from the first embodiment in that: the ballistic-resistance power device is a cylinder-type ballistic-resistance power structure.

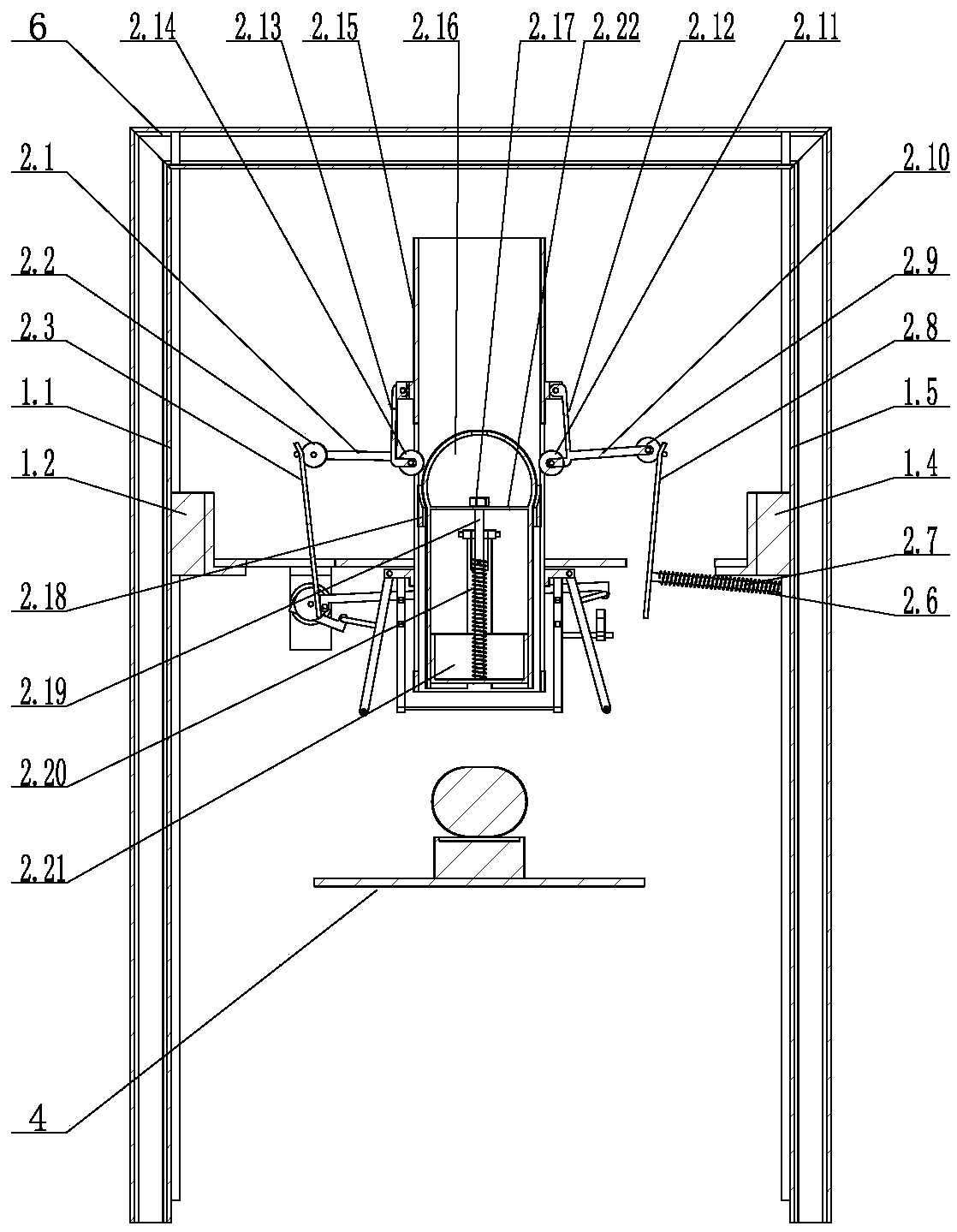

[0087] The cylinder-type anti-ballistic power mechanism includes an upper left anti-ballistic cylinder and an upper right anti-ballistic cylinder, and the upper left anti-ballistic cylinder and the upper right anti-ballistic cylinder are respectively installed on the left and right sides of the outer wall of the upper mold barrel, and are installed on the left side of the upper left articulated arm The left tie rod is installed on the right side of the upper right articulated arm. The telescopic shaft of the upper left ballistic cylinder is hinged to the left tie rod, and the telescopic shaft of the upper right ballistic cylinder is hinged to the right tie rod; When retracting, the left upper articulated arm and the right upper articulated arm can be driven to open outward through the left pull rod and the right ...

Embodiment 3

[0091] In this embodiment, the structure of the upper net mechanism is different from the first and second embodiments, and this embodiment is also provided with a lower net mechanism.

[0092] Such as Figure 10 , 11 Shown in and 12, the fully automatic fruit foaming mesh belt packaging machine described in the present embodiment includes a frame and a transmission device, and the transmission device includes a transmission chain; the middle part of the frame is provided with a fruit packaging position, and the transmission chain passes through Pass the fruit packaging position; install and fix the lifting chain plate on the conveyor chain; set the upper netting mechanism on the upper part of the frame, and the upper netting mechanism is set above the conveyor chain; the upper netting mechanism is driven by the netting power mechanism to move up and down The upper netting mechanism includes an upper mold cylinder and an upper mold core, the upper end of the upper mold core i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com