Screen distance adjustor

A technology for regulators and handles, which is applied in hand-held tools and manufacturing tools, can solve the problems of poor reliability and misoperation of adjacent running screens, and achieve the effect of good reliability and vibration avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the drawings.

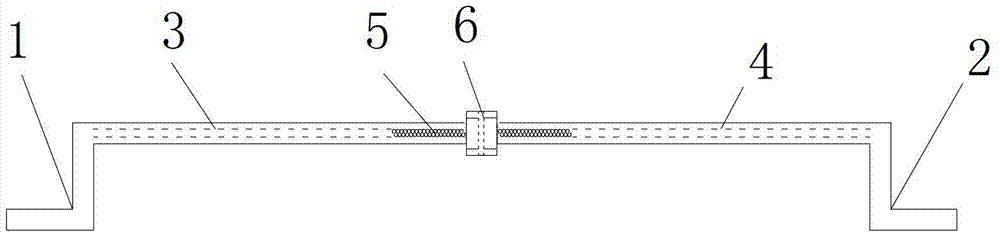

[0011] Reference figure 1 , A screen pitch adjuster, comprising a left fixing seat 1 and a right fixing seat 2. The left fixing seat 1 is fixedly connected to the left internally threaded pipe 3, and the right fixing seat 2 is fixedly connected to the right threaded pipe 4. The thread direction of the left internally threaded tube 3 is opposite to the thread direction of the right threaded tube 4, the left section of the screw 5 is installed in the left threaded tube 3, and the right section of the screw 5 is installed on the right threaded tube 4 Inside, the middle part of the screw 3 is an adjustment handle 6.

[0012] Further, the adjusting handle is a nut, and a through hole for inserting a screwdriver is provided in the nut.

[0013] In this embodiment, the screen pitch adjuster uses galvanized steel as the main component, and its strength meets the force requirements for opening t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com