Portable tool box in match with tool cabinet

A technology for portable tools and tool boxes, which is applied in the field of tool boxes and can solve problems such as restricting individual movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

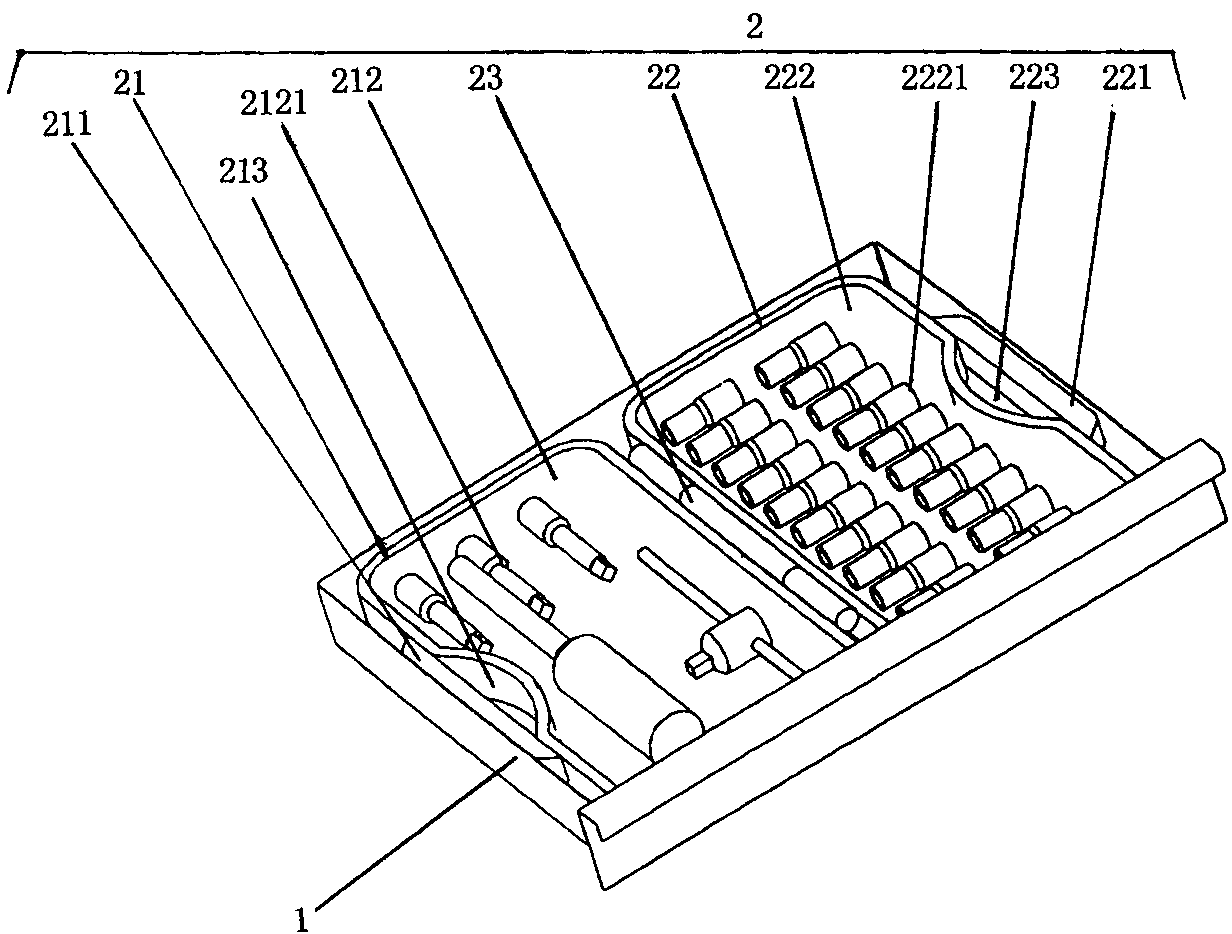

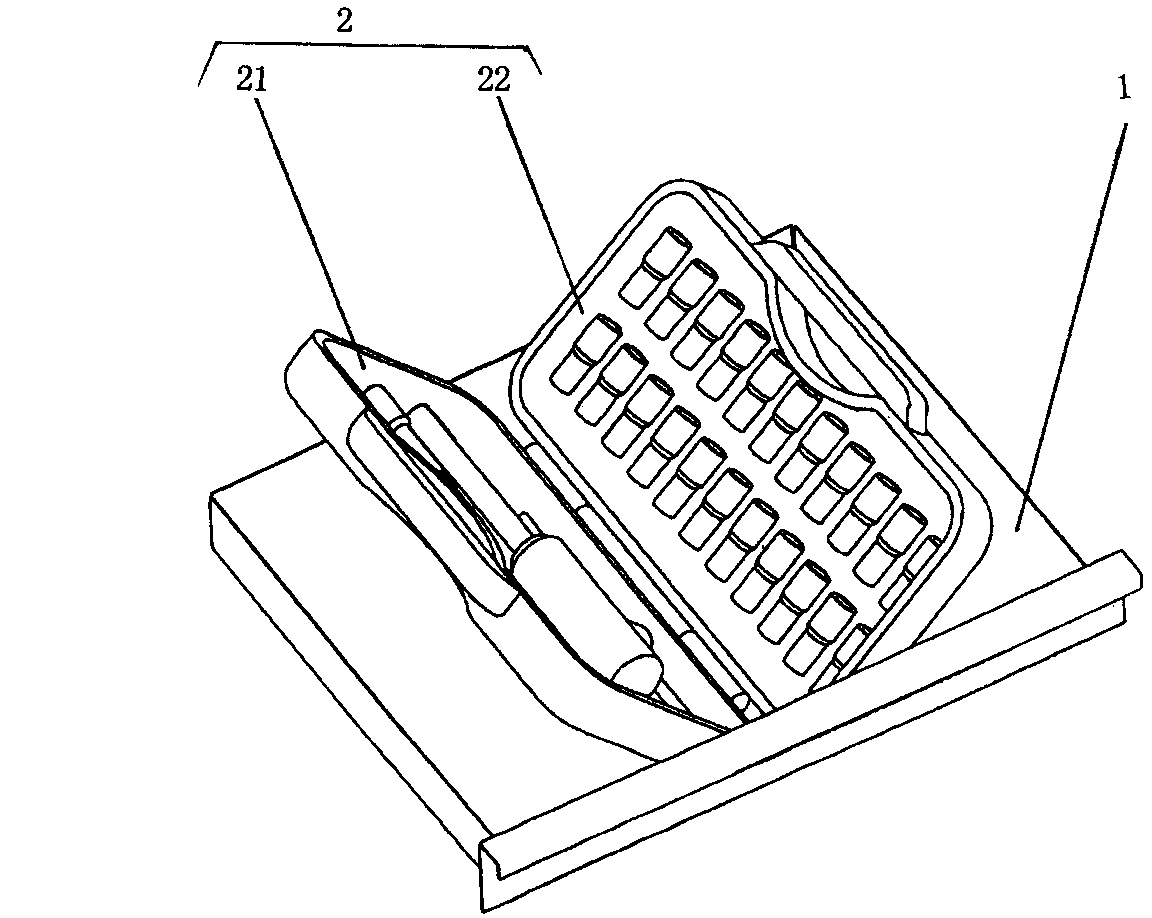

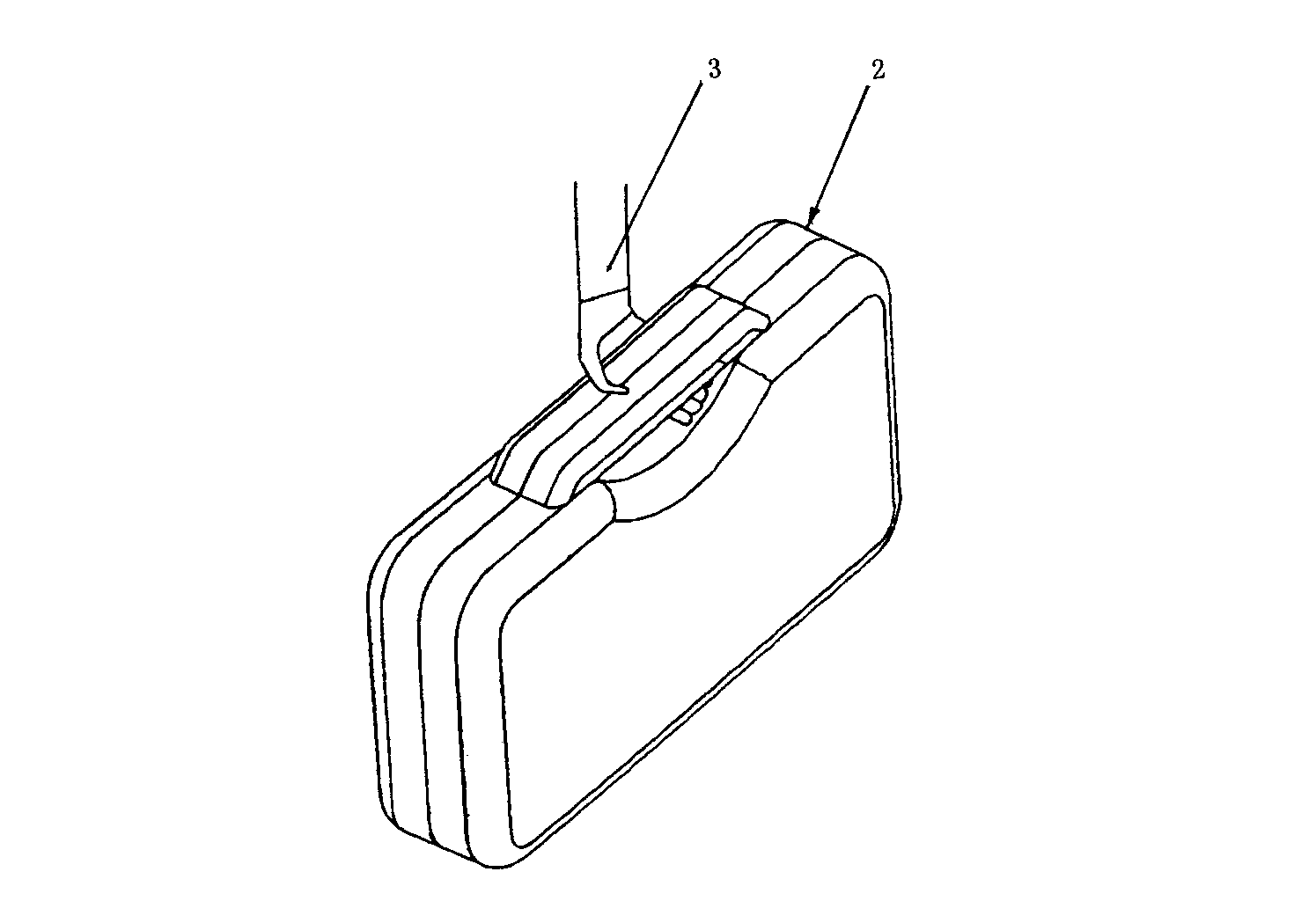

[0018] See figure 1 , the drawer 1 of the toolbox cabinet is provided, and the tool box body 2 of the structure of the present invention is configured on the drawer 1, and the tool box body 2 includes a first blister box flap 21, a second blister box flap 22 and Hinge 23, the shape and size of the first and second blister box flaps 21, 22 are the same, a first handle 211 is formed on the first blister box flap 21, and a first handle 211 is formed on the second blister box flap 22 The second handle 221, the positions of the first and second handles 211, 221 correspond, and when the first and second blister box flaps 21, 22 are closed (also called closed), the first and second The handles 211, 221 are then closed. Moreover, the first blister box flap 21 has a first tool receiving chamber 212 , and the second blister box flap 22 has a second tool receiving cavity 322 , and the depths of the first and second tool receiving chambers 212 and 222 are equal. The aforementioned hinge...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap