Stripe luminous fabric

A technology of light-emitting fabrics and fabrics, applied in the field of textile fabrics and fabrics, can solve the problems of no layering and single fabric structure, and achieve the effect of enhancing layering and enhancing warmth retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

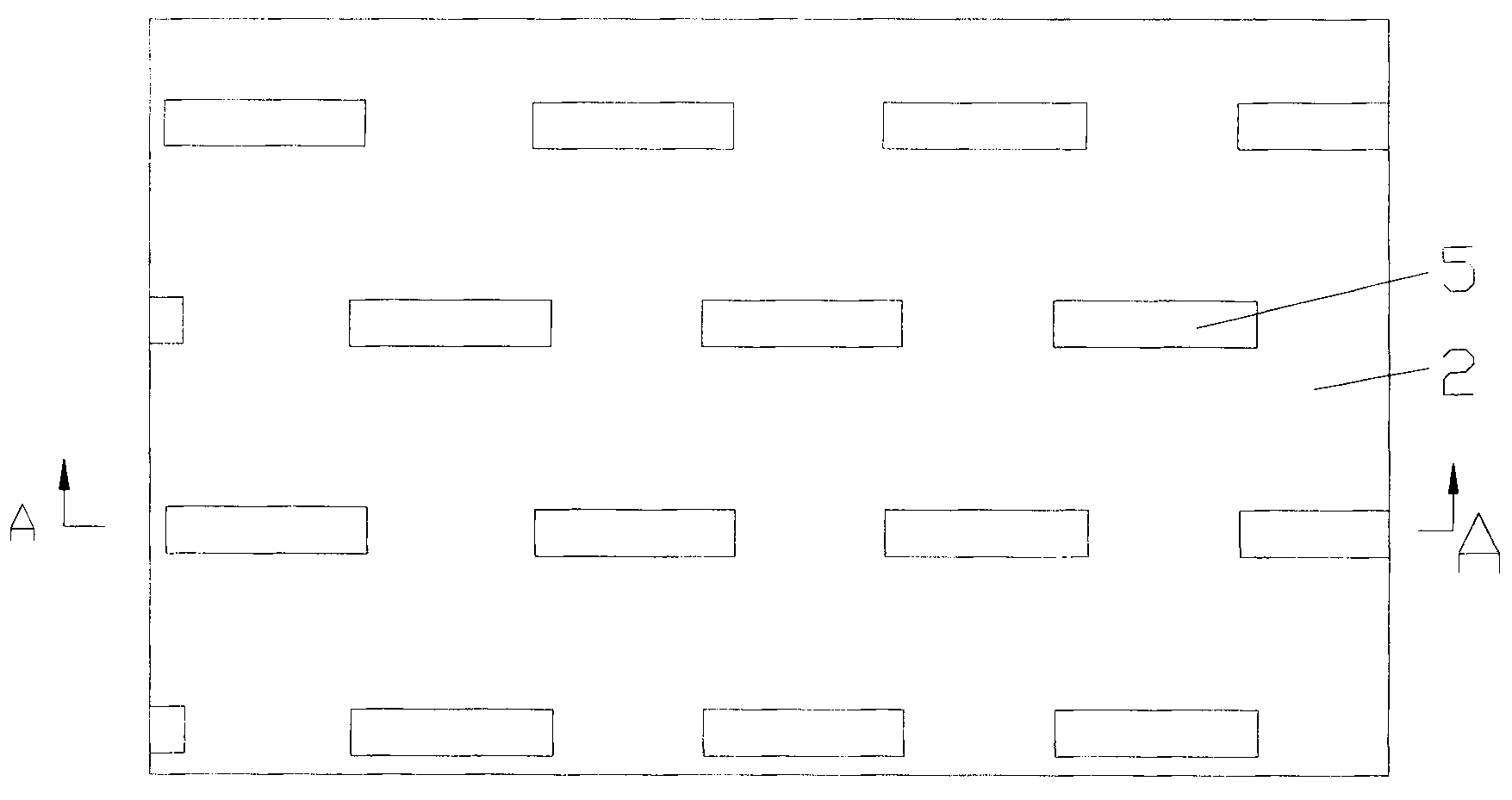

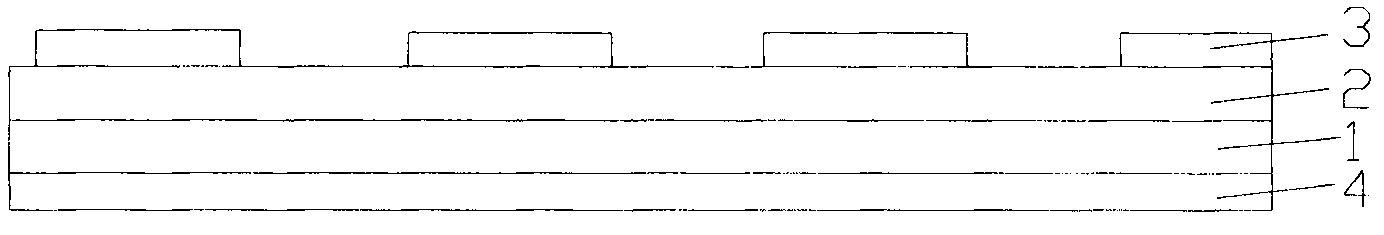

[0016] see figure 1 and figure 2 , The present invention relates to a striped luminescent fabric, which includes a fabric body 1, a fine-grain fabric layer 2 is provided on the front of the fabric body 1, and the fine-grain fabric layer 2 is connected to the fabric body 1 by a thread. On the fine-weave fabric layer 2 , coarse-grain rectangular short strips 3 are distributed, and the short strips 3 are arranged in a staggered manner in the horizontal direction, and are fixed on the fine-grain fabric layer 2 with threads. The surface of the short strip of cloth 3 is coated with a luminous body 5, which is a long phosphorescent phosphor or a rare earth long afterglow phosphor; Fabric Body1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com