A manufacturing method for identification and decoration member of clock surface

A decorative component and literal technology, which is applied in the field of marking and decoration on the surface of watches and clocks, and can solve the problems of high cost, lack of layering, and easy falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further description will be given below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection of the present invention is not limited thereto.

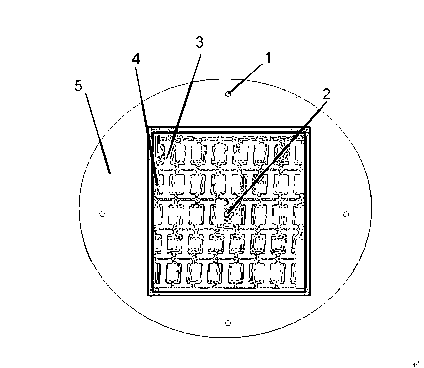

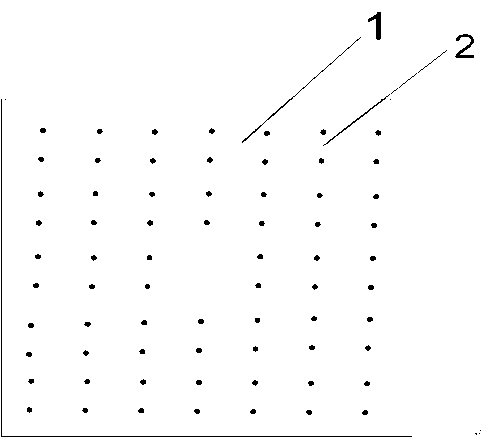

[0015] figure 1 As shown, it is a picture of a semi-finished product that has been processed. The 1 and 2 shown in the figure are all positioning holes, and the number of positioning holes is plural on the base material. Shown in figure 3 is the position that needs to be reserved after twice CNC processing on the base material, namely the product produced by the present invention. It will be detached from the base material 5 when the reverse side is processed for the second time. The position of 4 in the figure is the required dispensing position, and its range is the range marked in the inner black box.

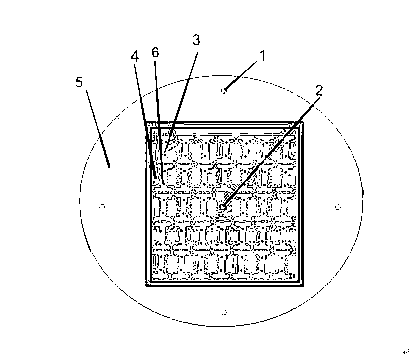

[0016] figure 2 As shown, it is a patented product that has been processed on both sides, and the leftovers have not been removed. 6 is the positioning hole (feet) on the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com