Method for preparing carbon nano tube by sunflower seed skin

A technology for carbon nanotubes and sunflower seeds is applied in the field of preparing carbon nanotubes, which can solve the problems of high cost of carbon nanotube raw materials, high energy consumption, harsh experimental conditions, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

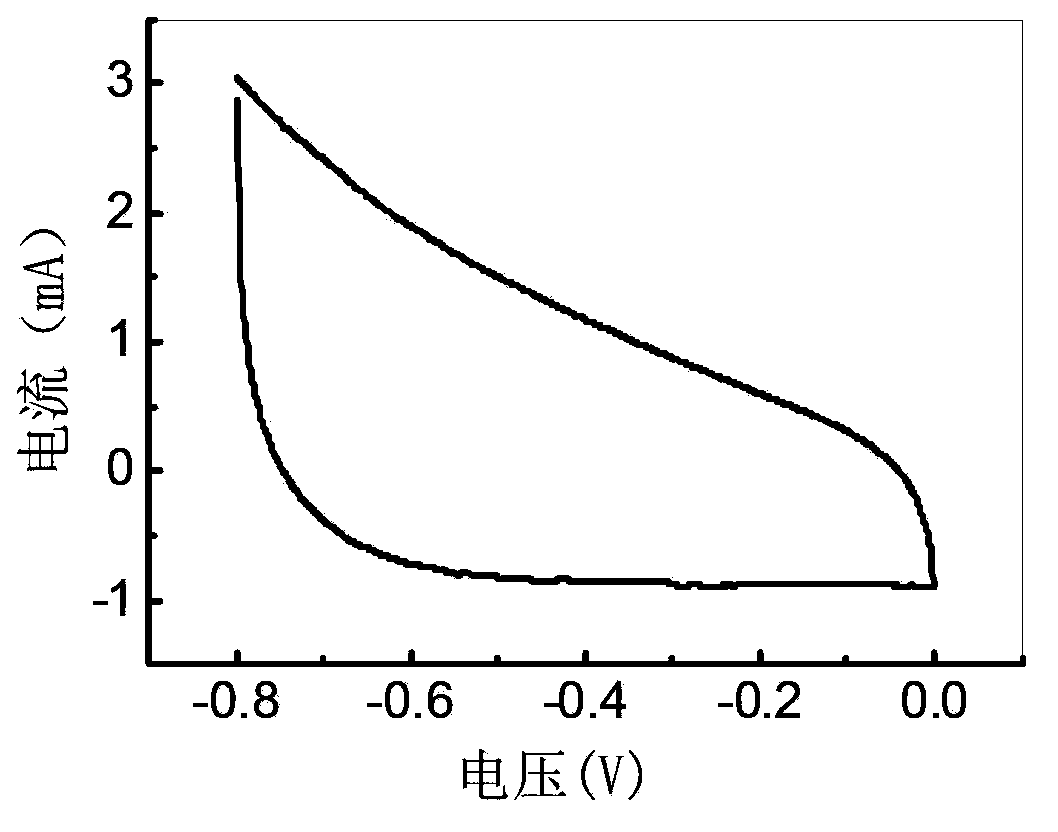

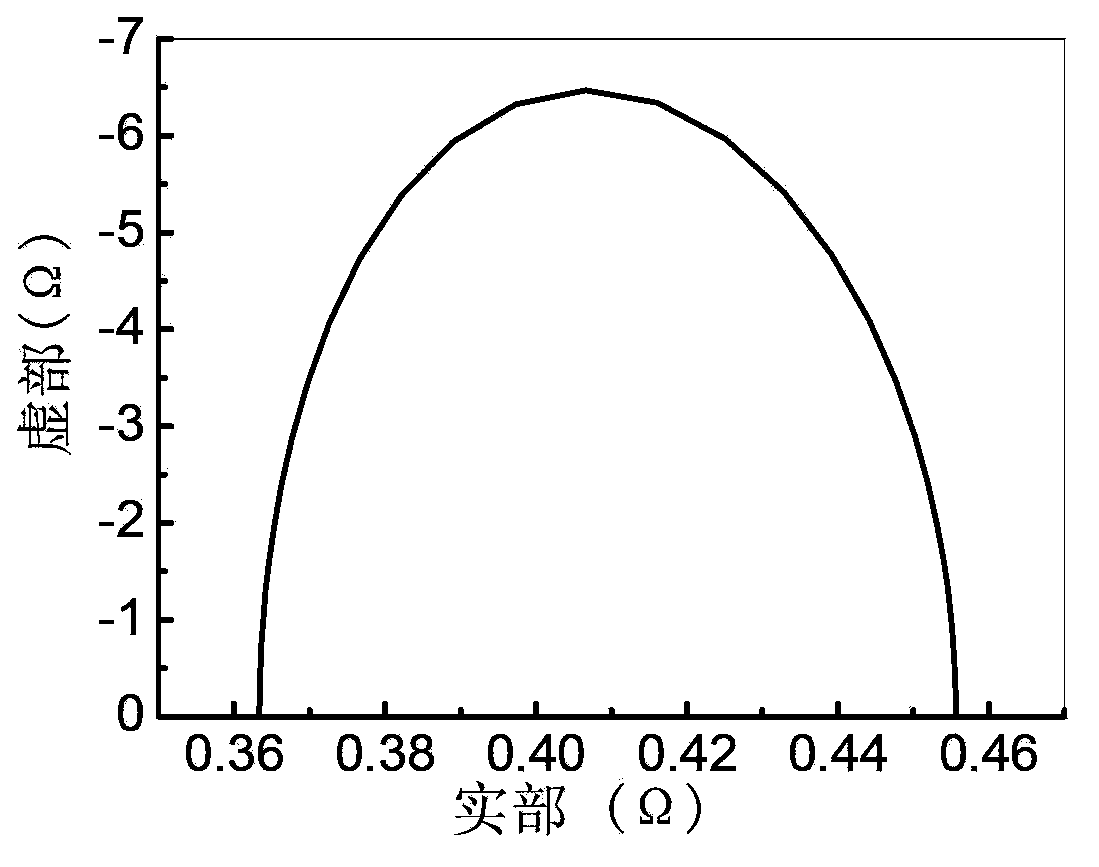

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: a kind of method that utilizes sunflower seed skin to prepare carbon nanotube, specifically is carried out according to the following steps:

[0018] 1. Place the quartz tube with sunflower seed husk in a high-temperature tubular resistance furnace, one end of the quartz tube is connected to the atmosphere, and the other end of the quartz tube uses a nitrogen bottle to flow into the quartz tube at a rate of 300mL / min~500mL / min. Nitrogen is fed for 0.5h~1.5h, and a protective bottle is connected between the nitrogen bottle and the tube furnace. Then, stop feeding nitrogen and seal the nitrogen end and the end connected to the atmosphere. The heating rate is 15°C / min, from room temperature to 400°C~1200°C, then keep the temperature for 2h~4h, and then naturally cool to room temperature to obtain the carbonized solid;

[0019] 2. Grind the carbonized solid in step 1 with a mortar for 10min~30min, then add 1mol / L~4mol / L nitric acid to the ground sol...

specific Embodiment approach 2

[0021] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the rate of introducing nitrogen in step 1 is 400mL / min. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is: the time for passing nitrogen in step 1 is 1 h. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com