Sintering method of ceramic concentric sphere

A technology of ceramic concentric balls and concentric balls, applied in the field of handicraft manufacturing, can solve the problems of cracking, easy deformation, easy cracking and deformation of ceramic concentric balls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] As shown in the figure, the present invention discloses a method for sintering ceramic concentric spheres by wrapping ceramic concentric sphere bodies with two cylindrical ceramic green bodies with hollow spherical cavities, including the following steps:

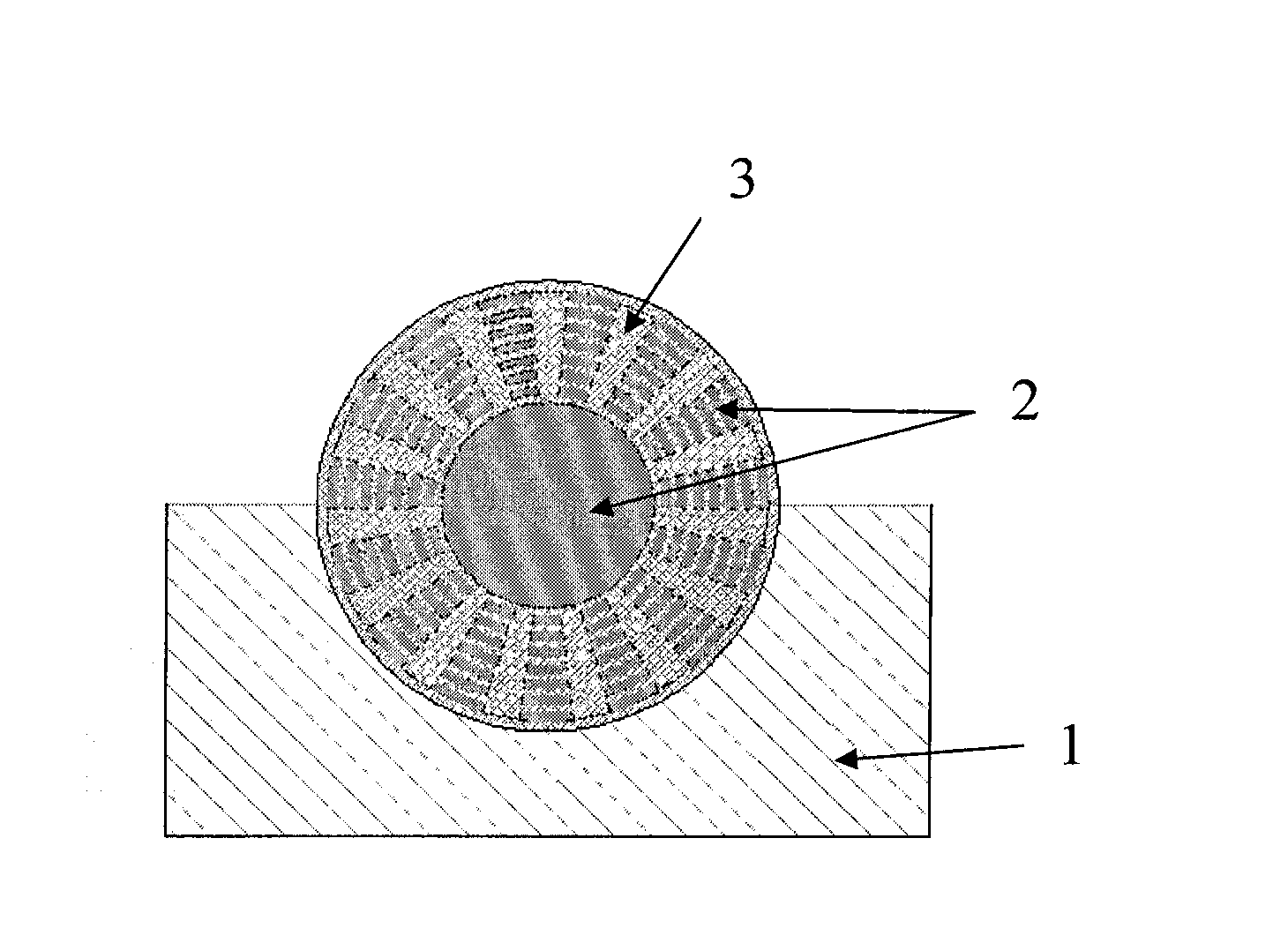

[0021] Step 1, after making the ceramic layer 2 of the last layer of ceramic concentric spheres, make a layer of isolation layer 3 on its surface;

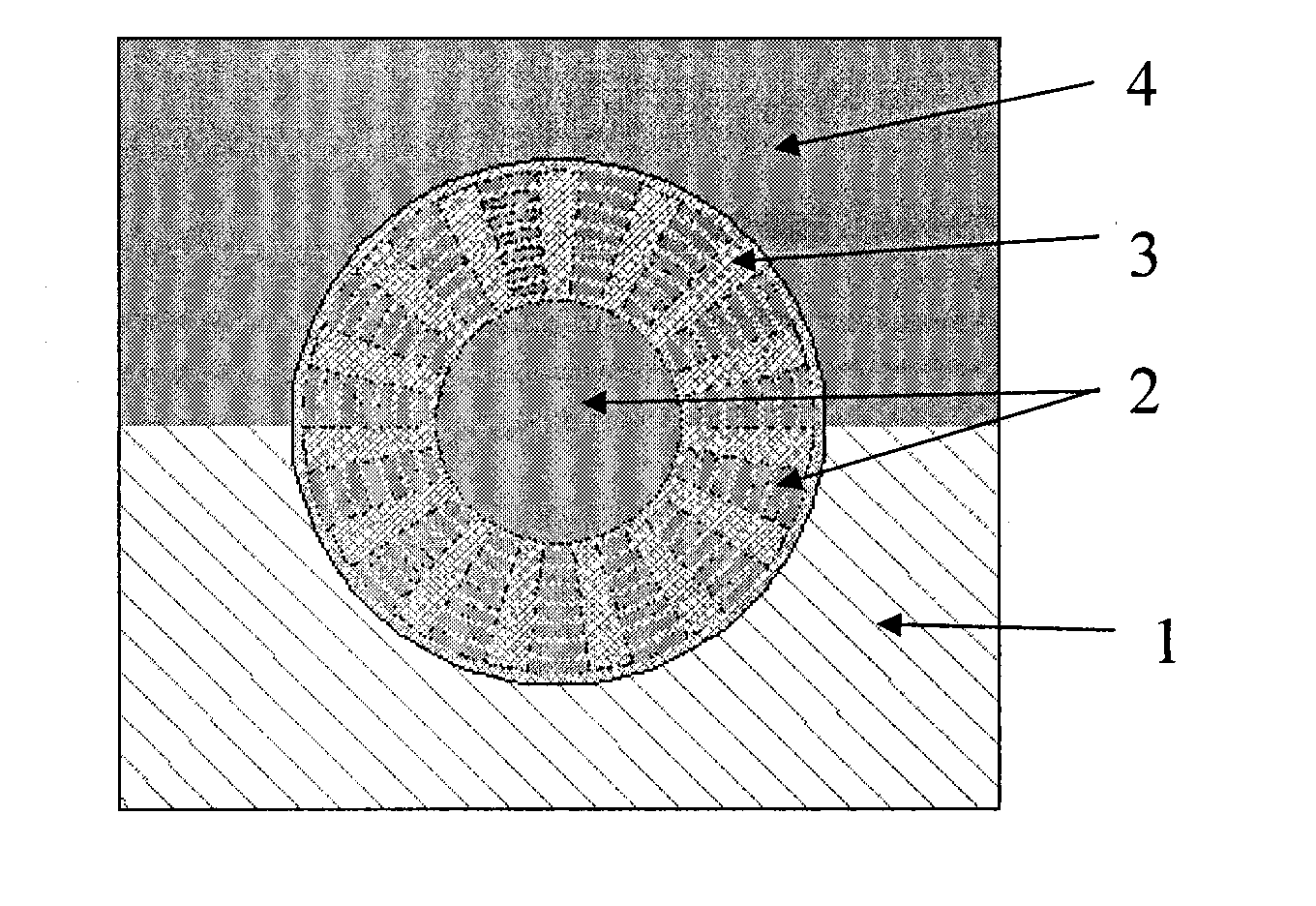

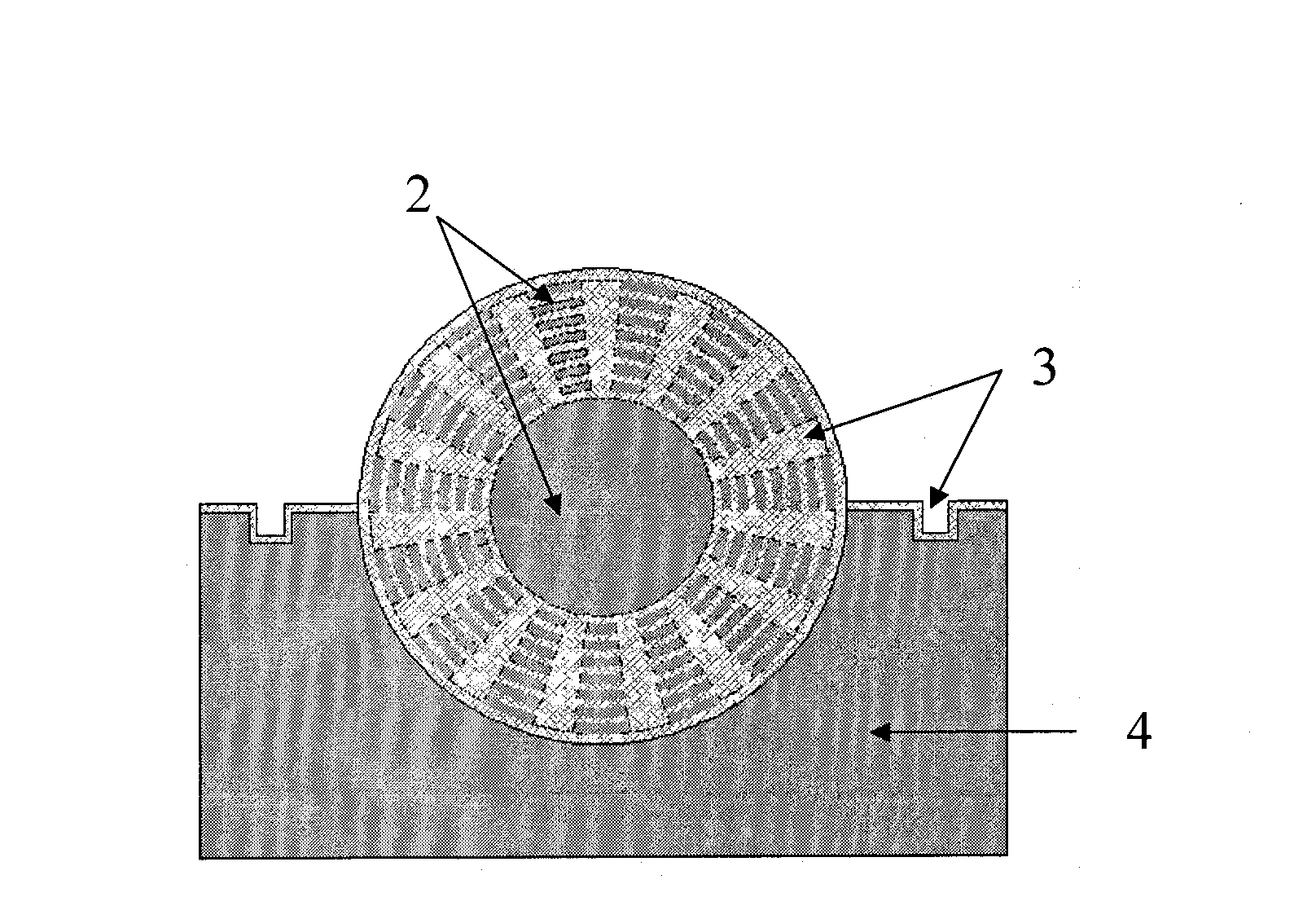

[0022] Step 2, still utilizing the mold for positioning the ceramic concentric sphere body 2 when making the isolation layer 3, so that the lower hemisphere part of the ceramic concentric sphere is still in the mold 1, exposing the upper hemisphere part, and using the materials and methods for making the ceramic layer on the isolation layer 3 A cylinder 4 is made on the outside of the upper hemisphere, allowing the cylinder to tightly wrap the upper hemisphere of the ceramic concentric sphere body;

[0023] Step 3: Flip the finished cylinder 4 together with the ceramic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com