Preparation method for super-hydrophobic polypropylene film

A polypropylene film and super-hydrophobic technology, which is applied in the preparation of super-hydrophobic polypropylene film and the preparation of hydrophobic film materials, can solve the problems of poor controllability and complicated process, and achieve low cost, good reproducibility and good industrialization The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

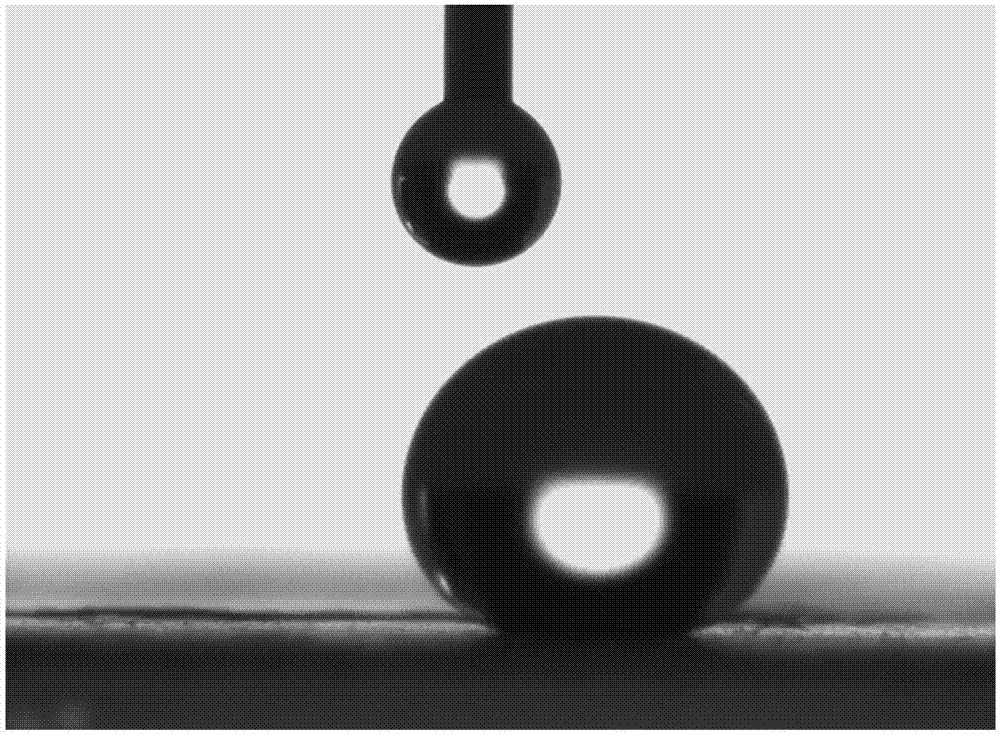

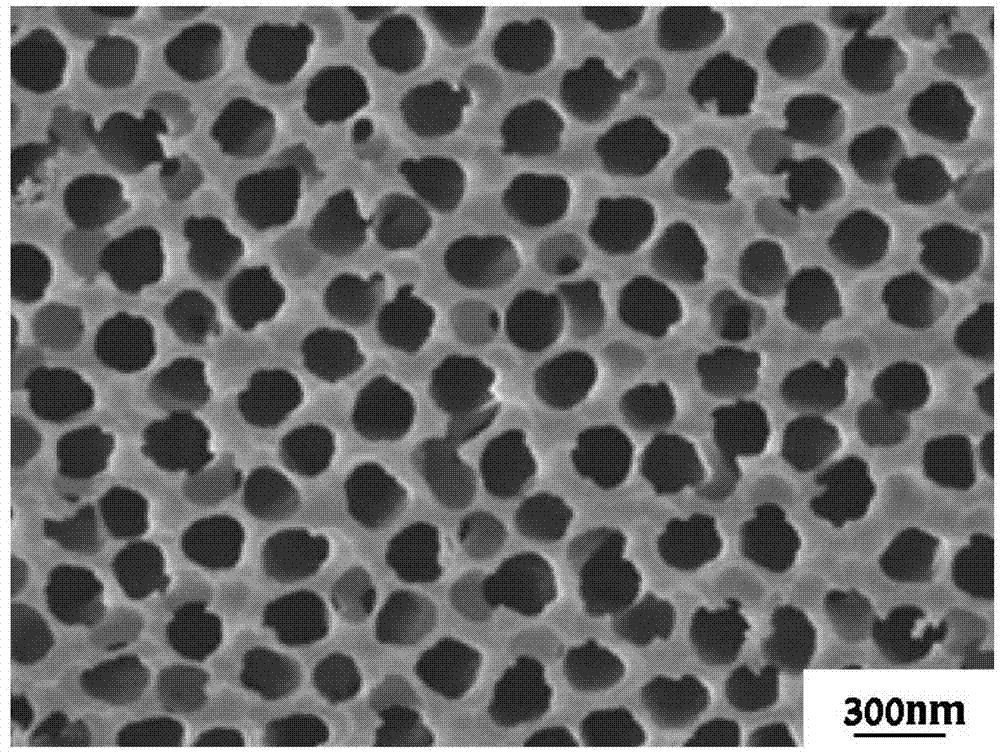

[0024] First, 10 grams of polypropylene pellets were weighed and dissolved in 1000ml of xylene at 120°C to form a polypropylene solution with a concentration of 10mg / ml; 85% and 20% ethanol vapor concentration at 80°C for 10 hours. During drying, the ethanol vapor and water vapor in the air penetrate into the surface of the polypropylene solution to form honeycomb pores, thereby obtaining a superhydrophobic surface. The obtained film is It is a superhydrophobic polypropylene film, and the surface of the superhydrophobic polypropylene film is honeycomb (such as figure 2 shown). Test the wettability of this film surface with OCA20 contact angle tester, the result shows that the contact angle of this film and water is 155 ± 1.9 ° (as figure 1 shown).

Embodiment 2

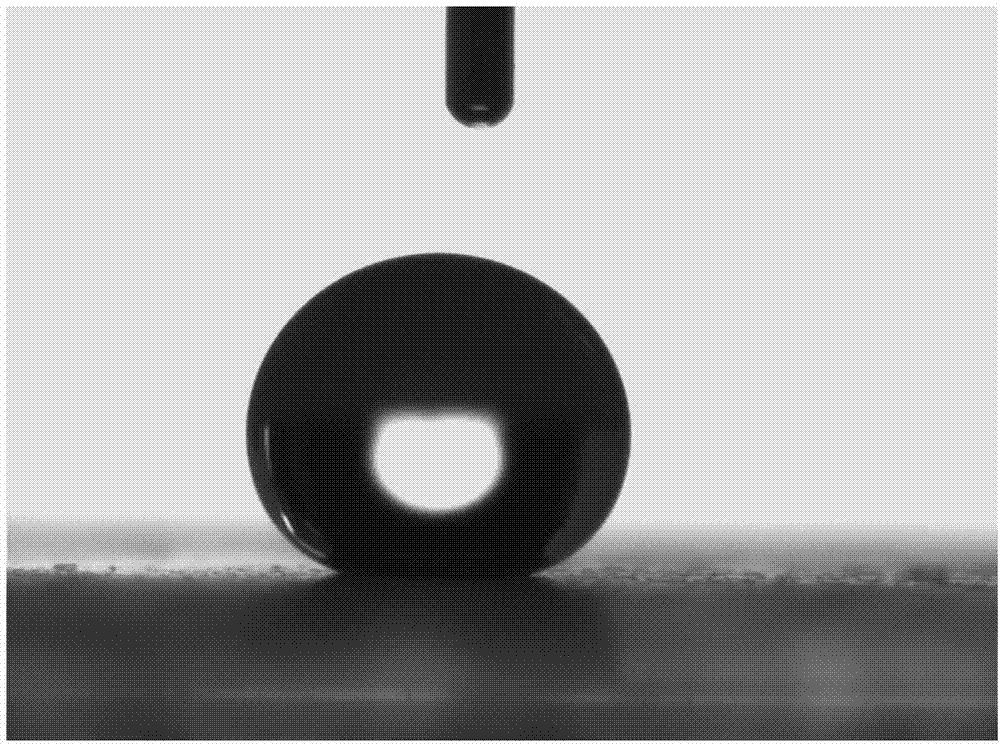

[0026] First, weigh 20 grams of polypropylene pellets and dissolve them in 1000ml of toluene at 120°C to form a polypropylene solution with a concentration of 20mg / ml; %, the ethanol vapor concentration is 5% and dried at 100°C for 15 hours. During drying, the ethanol vapor and water vapor in the air penetrate into the surface of the polypropylene solution to form honeycomb holes, thereby obtaining a super-hydrophobic surface. The resulting film is Superhydrophobic polypropylene film. Test the wettability of this film surface with OCA20 contact angle tester, the result shows that the contact angle of this film and water is 156 ± 1.6 ° (as image 3 shown).

Embodiment 3

[0028] First, weigh 50 grams of polypropylene pellets and dissolve them in 1000ml of benzene at 120°C to form a polypropylene solution with a concentration of 50mg / ml; %, the ethanol vapor concentration is 15% and dried at 120°C for 15 hours. During drying, the ethanol vapor and water vapor in the air are used to infiltrate the surface of the polypropylene solution to form honeycomb holes, thereby obtaining a super-hydrophobic surface. The obtained film is Superhydrophobic polypropylene film. Test the wettability of this film surface with OCA20 contact angle tester, the result shows that the contact angle of this film and water is 156 ± 1.8 ° (as Figure 4 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com