Method for preparing lactic acid by soapberry seed shell

A technology of Sapindus chinensis and lactic acid, applied in fermentation and other directions, can solve the problems of high cost and large food consumption, and achieve the effect of small investment, reduced consumption and large amount of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

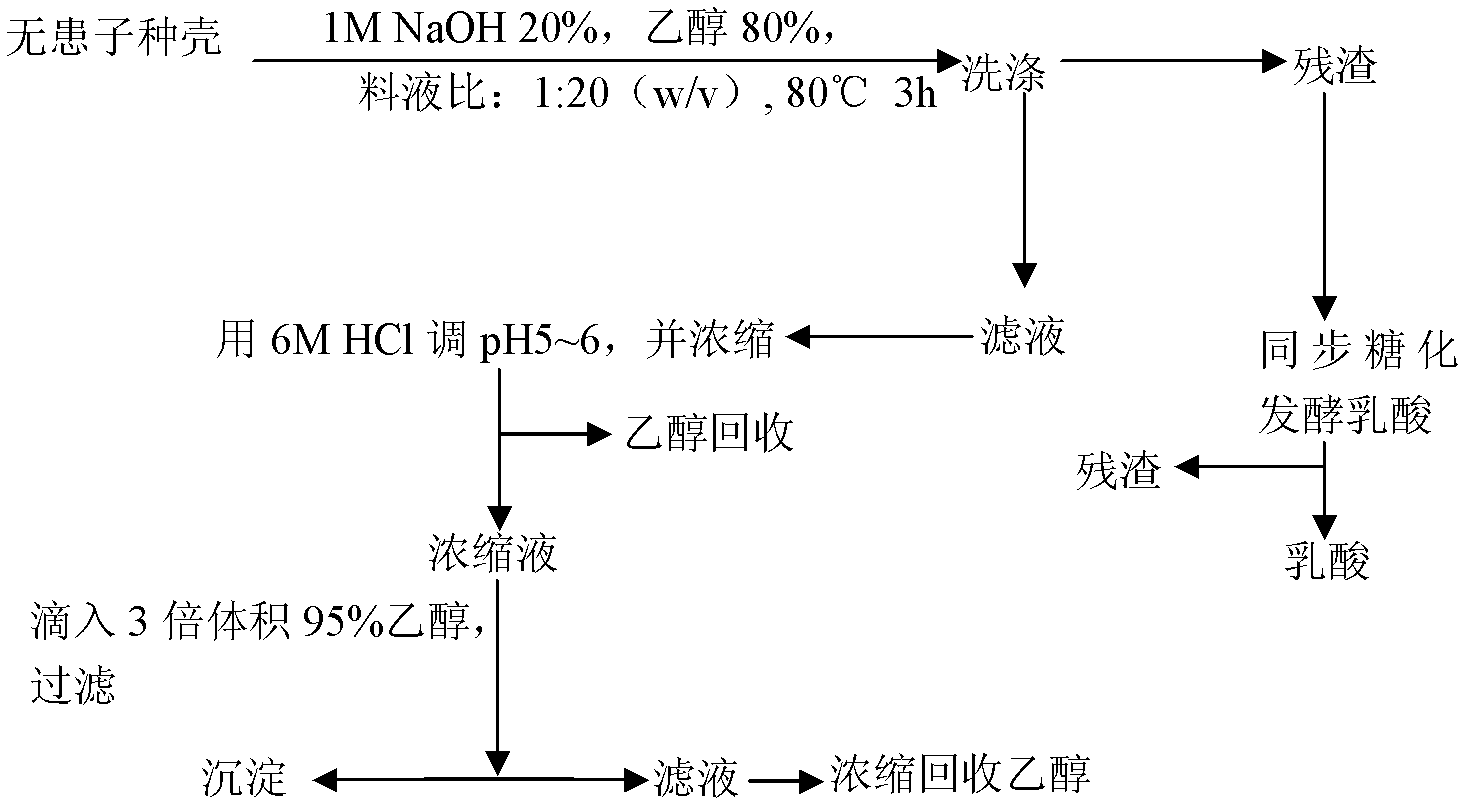

Image

Examples

Embodiment 1

[0020] Put 1 kg of sapindus seed husks crushed into 40 meshes in 20 L of alkali-alcohol solution (20% 1M NaOH solution, 80% ethanol), treat at 80°C for 3 hours, then filter, wash the residue with hot water until neutral, and then carry out synchronous saccharification Fermentation converts lactic acid. In 1 liter of fermentation system, the addition amount of alkali-alcohol-treated Sapindus seed husk is 130 g, the addition amount of cellulase is 15 FPU / g cellulose, and the addition amount of lactic acid bacteria strain is 3 g (dry matter). Carry out synchronous saccharification and fermentation for 120 hours, the reaction temperature is 45° C., and the pH value is 4.8. The composition of the fermentation medium is KH 2 PO 4 0.5g / l, MgSO 4 ·7H 2 O 0.5g / l, NaCl 0.1g / l, beef extract 5g / l, solid CaCO 3 20g / l. The yield of lactic acid is 99.5%.

Embodiment 2

[0022] Put 1 kg of sapindus seed husks crushed into 40 meshes in 20 L of alkali-alcohol solution (20% 1M NaOH solution, 80% ethanol), treat at 80°C for 3 hours, then filter, wash the residue with hot water until neutral, and then carry out synchronous saccharification Fermentation converts lactic acid. In 1 liter of fermentation system, the amount of sapindus seed husks treated with alkali alcohol is 150 g, the amount of cellulase is 15 FPU / g cellulose, and the amount of lactic acid bacteria is 2 g (in terms of dry matter). Carry out synchronous saccharification and fermentation for 96 hours, the reaction temperature is 48°C, and the pH value is 4.8. The composition of the fermentation medium is KH 2 PO 4 0.5g / l, MgSO 4 ·7H 2 O 0.5g / l, NaCl 0.1g / l, beef extract 5g / l, solid CaCO 3 20g / l. The yield of lactic acid was 92.8%.

Embodiment 3

[0024] Put 1 kg of sapindus seed husks crushed into 40 meshes in 20 L of alkali-alcohol solution (20% 1M NaOH solution, 80% ethanol), treat at 80°C for 3 hours, then filter, wash the residue with hot water until neutral, and then carry out synchronous saccharification Fermentation converts lactic acid. In 1 liter of fermentation system, the amount of sapindus seed husks treated with alkali alcohol is 120 g, the amount of cellulase is 15 FPU / g cellulose, and the amount of lactic acid bacteria is 4 g (in terms of dry matter). Carry out synchronous saccharification and fermentation for 120 hours, the reaction temperature is 46°C, and the pH value is 4.8. The composition of the fermentation medium is KH 2 PO 4 0.5g / l, MgSO 4 ·7H 2 O 0.5g / l, NaCl 0.1g / l, beef extract 5g / l, solid CaCO 3 20g / l. The yield of lactic acid was 98.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com