Sample warper

A warping machine and fancy technology, applied in warping machines, textiles, papermaking, tool manufacturing, etc., can solve the problems of warp yarn cutting and unwinding difficulty, increasing difficulty, warping speed limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

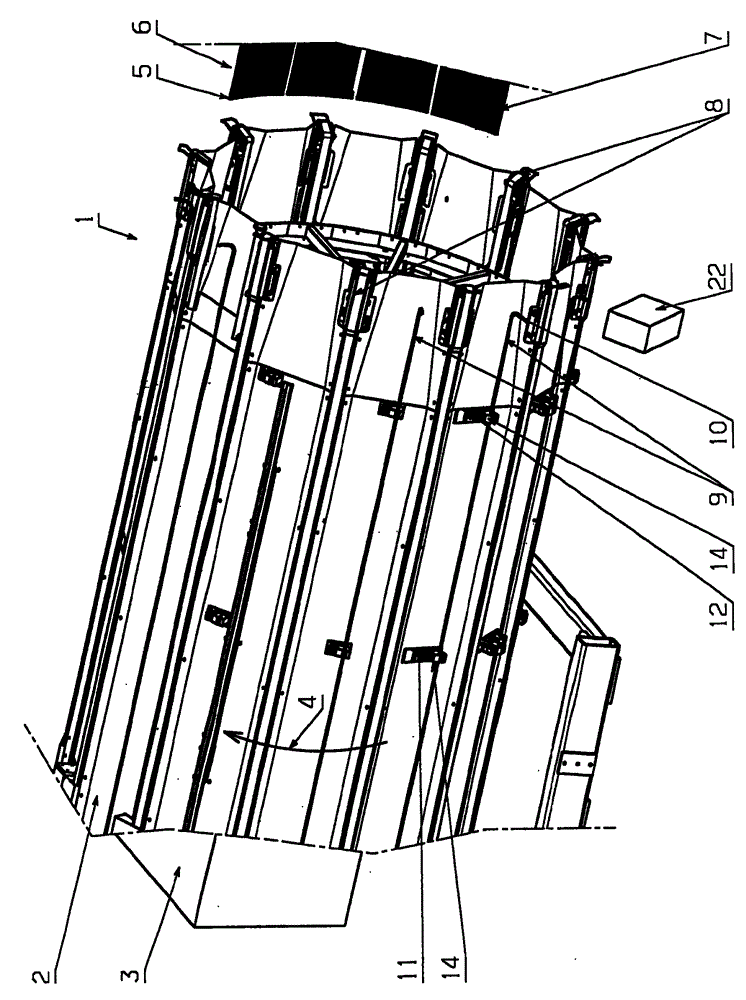

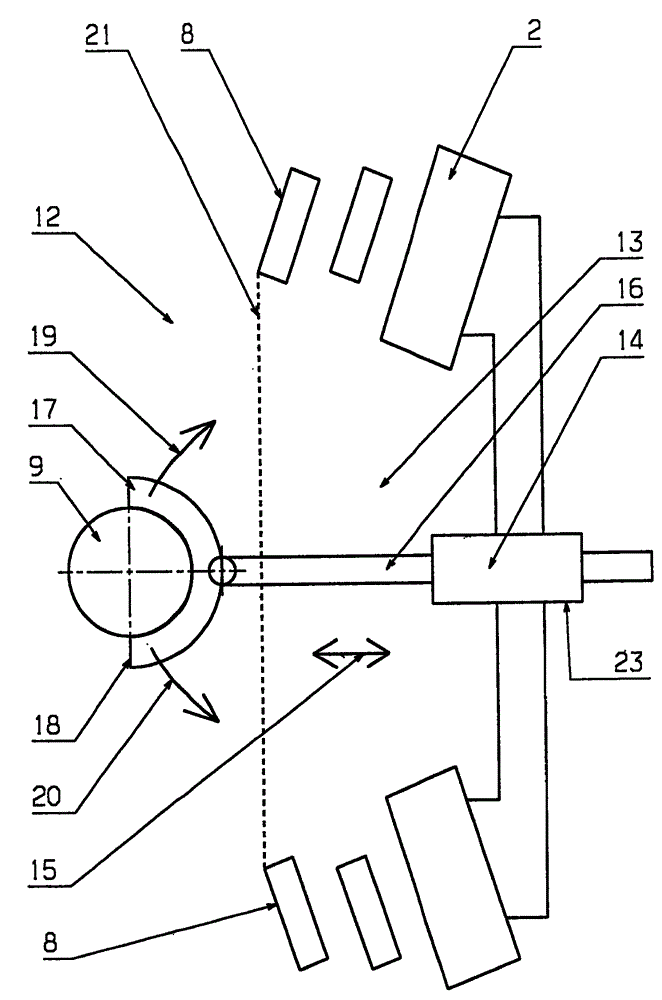

[0023] figure 1 A pattern warping machine 1 is shown schematically with a warping cylinder 2 connected to a rotary drive 3 which is only schematically shown. During winding, the rotary drive 3 is able to turn the warping cylinder 2 in the direction indicated by the arrow 4 .

[0024] A plurality of bobbins are mounted on creels, not shown in detail. In this exemplary embodiment, up to 128 bobbins can be mounted on the creel. The thread is drawn from each bobbin and guided through the thread guide eyelet 5 of the thread guide 6 . All yarn guides 6 together form a yarn guide device 7 .

[0025] During warping, that is to say during the production of warp effects, the thread guide 6 is at rest in the direction of rotation 4 of the warping cylinder 2 . However, the thread guide 6 can be moved in the axial direction, that is to say parallel to the axis of the warping cylinder 2 , to be precise, the thread guide eyelets 5 are guided in the axial direction on the warping cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com