Transmission shaft sealing device of grate coolers

A technology of sealing device and transmission shaft, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., which can solve the problems of reduced work efficiency, time-consuming and troublesome, difficult pressure balance adjustment of seal 56, etc., and achieves convenient lubricating oil and easy disassembly Easy and convenient pressure adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

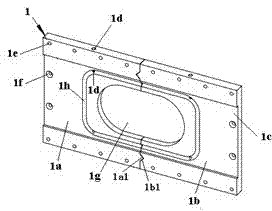

[0050] control figure 1 The sealing plate 1 is a rectangular plate and is formed by splicing the first half sealing plate 1a and the second half sealing plate 1b. The chute 1c provided on one side of the sealing plate 1 is set at the center of the bottom surface of the chute. A waist-shaped hole 1g, a rectangular annular oil groove 1h is also provided on the bottom surface of the chute around the periphery of the waist-shaped hole 1g; and the above-mentioned waist-shaped hole 1g and oil groove 1h are respectively arranged in the first half of the sealing plate 1a in two completely symmetrical parts and on the second half-sealed plate 1b. At least one triangular protrusion 1a1 and a triangular groove 1b1 are provided on the splicing surface 1i of the two halves of the sealing plate; preferably as figure 1 As shown, a triangular protrusion 1a1 and a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com